Adhesion tendency, wearing properties and cleaning efforts of ta-C coated surfaces applied in food processing plants

(Bio)-Fouling is one of the major risk factors in the food processing industry with respect to product safety and the resulting health threat to con-sumers. In particular contaminants from surface biofilms being in contact with the raw materials and products pose threats to the processed food. Parts of the bacterial communities can be stripped off and distributed in the processing equipment and products. For this reason, food producers undertake big efforts to eliminate (bio)-fouling. These efforts include strategies to prevent adhesion of contaminants as well as efficient cleaning and disinfection routines to shorten shut-down periods.

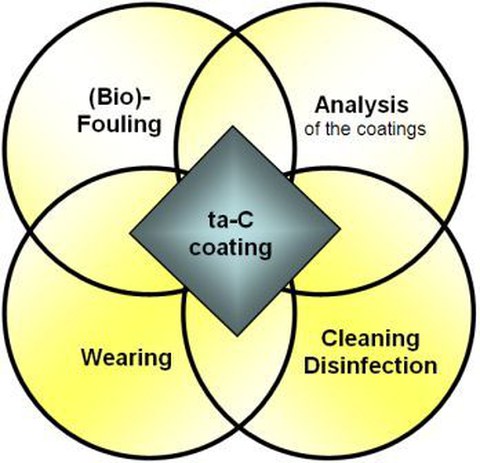

In this context, the aim of this project is to test innovative ta-C coatings on food processing blades. Therefore it is intended to study:

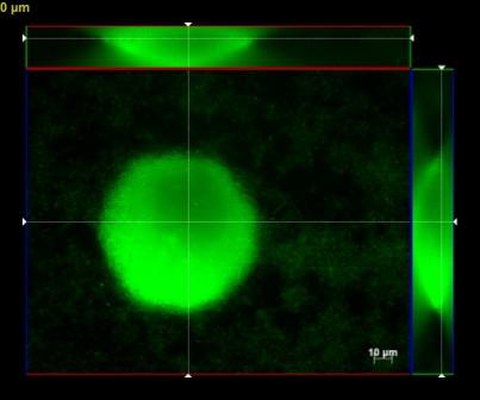

- The adhesion tendency of bacteria and/or food macromolecules on ta-C coatings by Atomic Force Microscopy.

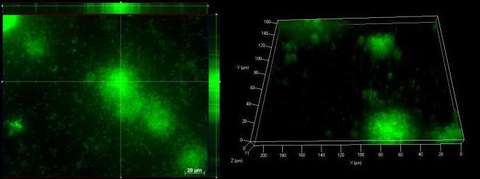

- (Bio)-fouling on ta-C coatings in flow chambers.

- The wearing behaviour of the ta-C coatings using food materials such as cheese or meat.

- Efficient cleaning and disinfection routines for the ta-C coatings.

This is a joint research project of TU Dresden (Institute of Food Technology and Bioprocess Engineering and Institute of Processing Machines and Mobile Machinery) and the Max Bergmann Center of Biomaterials. The Biomonitoring group of the Institute of Food Technology and Bioprocess Engineering is working on dynamics of bacterial growth and biofilm formation on anti-fouling-surfaces. Therefore the spatio temporal distribution of bacteria biofilms is studied and mathematical models are built.

Project financing:

- Arbeitsgemeinschaft industrieller Forschungsvereinigungen "Otto von Guericke" e.V. (AiF)

- Industrievereinigung für Lebensmitteltechnologie und Verpackung e.V.

Project term:

01.09.2010 - 28.02.2013

Contact:

Mulansky, Boschke, Bley