Cleaning Technologies

The cleaning of machines and facilities is a decisive process to maintain product quality in the food processing industry. At the same time, requirements for environmental protection and efficiency increase, resulting in a discrepancy between safety for the consumer and a minimum use of resources. Therefore, the optimisation of cleaning processes is of great importance. In addition to focusing on food technology, we see ourselves as a cross-industry competence provider for automated industrial cleaning tasks.

In close cooperation with the Fraunhofer IVV Dresden we are well networked on a national and international level. This ensures you, as an industrial partner, interdisciplinary access to international research as well as a wide range of opportunities in the field of research funding.

Overview flyer as pdf-download

The research group is dedicated to the development of methods for the investigation of the cleaning progress and the process influences for open and closed systems including the application of novel flow regimes. This includes solutions for the following sub-steps/processes:

- selection and development of model soils,

- cleaning relevant characterisation of soils,

- defined application of soils on complex surfaces,

- characterisation of liquid jets and films,

- quantified monitoring of the cleaning progress,

- evaluation of cleaning efficiencies,

- automated data evaluation and interpretation of results as well as

- cleaning simulations to increase the understanding of the process and for purposeful optimisation.

In addition, the test rigs are used to assess the cleanability of components and surfaces in contact with the product.

We contribute to the development of innovative products and provide development impulses for component manufacturers. In addition, we optimise the cleanability of your machines and facilities and do research on the resource-saving production in processing companies.

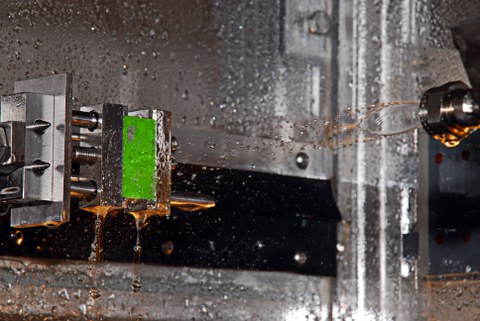

Spray cleaning test rig

The spray cleaning test rig allows the imitation of automated cleaning processes up to a volume flow rate of 10 l/min, a pressure of 8 bar and a media temperature of 60 °C. A monitoring unit can be used to document the cleaning progress of test components on a cm-scale and thus to analyse the effect of different influencing factors. In this test rig both intermittent and continuous cleaning with nozzles of different designs can be investigated.

Flush Cleaning Test Facility

The flush celaning test facility offers the possibility to investigate the flushing process of highly viscous processed goods (food, cosmetics) in closed pipe systems. With the help of the integrated measurement technology and the developed measurement methodology, it is possible to improve industrial flush cleaning when changing products and to reduce the waste of a possible mixing phase. The modular design also enables the investigation of different system components.

Modular test rig for CIP processes

The modular cleaning test rig is used to simulate industrial cleaning in place (CIP) processes. Using standard DN50 connections, the cleaning of components and assemblies with flow rates of up to 5.5 m³/h can be investigated.

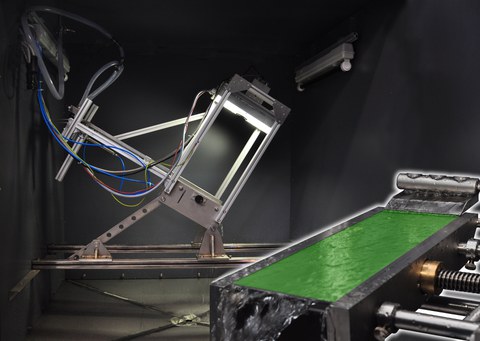

Falling film test rig

The falling film test rig enables the investigation of cleaning processes by means of gravitation-driven liquid films. In addition, the test rig can be used to study wetting conditions and to determine flow parameters (e.g. film thickness). Continuous and discontinuous flows can be studied.

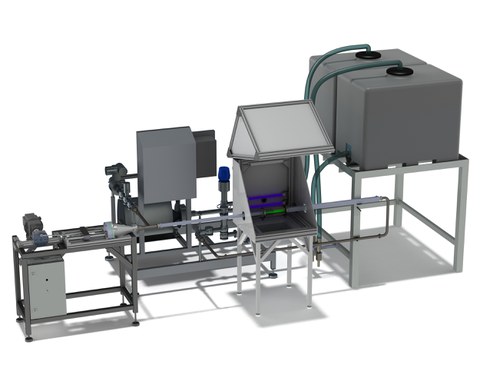

Parts washing machine

The parts washing machine enables spray cleaning tests on complex components with maximum dimensions of 1 m x 1 m x 1.5 m (width x height x length), with an adjustable flow rate of up to 16 m³/h or operating gauge pressure of up to 4 bar. In addition, a torispherical head with industrial installations for testing tank cleaners is available.

- Spray cabin with robot

- 10 m³ test tank

- High-pressure pump

- Foam applicator

- Measuring instruments for spray and jet characterization

- Equipment for soil application and characterization

An overview of further research projects can be found here.