Development of an aerosol former for the production of conditioned fleece for low-water paper and cardboard production

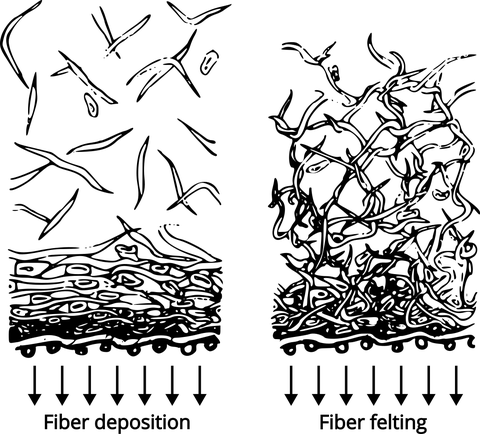

Mechanisms of dry fleece formation

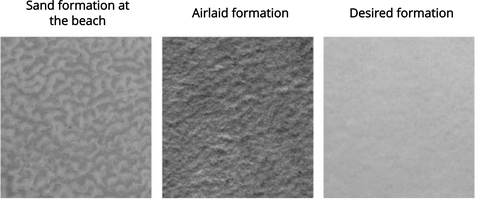

Paper and cardboard packaging are particularly sustainable and recyclable products, as they are primarily made from renewable raw materials and can be recycled many times in the closed waste paper system. Current manufacturing processes for paper fleece are the conventional wet process (fiber transport in water) or dry processes, such as the airlaid process (fiber transport in air). The disadvantage of wet processes is that they require a lot of water and energy, while the thickness and density of the fleece varies greatly in dry processes.

The PAerForM project is focusing on the development of a procedure for the production of paper fleece with low resource and energy consumption and improved fleece quality compared to current dry processes.

The Chair of Fluid Mechanics is working on the analysis of the fibre-loaded flow and the deposition process. Numerical simulations and experimental studies are used to investigate the influence of flow parameters and design on fleece formation. Based on this, solutions for the technical implementation of the system and for process control are developed.

| Cooperation |

Arbeitsgruppe Papiertechnik, TU Dresden |

| Funding |

“Central Innovation Programme for small and medium-sized enterprises (SMEs)” (ZIM) - Cooperation part KF (Funding reference KK5482602BU4) |

| Contact |