Project Aims

Table of contents

a) Soft lithography

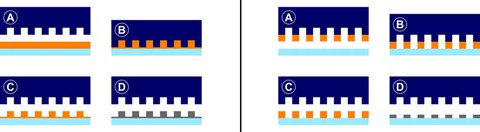

The preparation of the nanostructured films was done by soft lithography using a µCP 3.0 micro-contact printer from GeSiM mbH. The stamps were prepared by curing a PDMS-precursor (Sylgard 184, Dow Corning) over an etched silicon wafer. For printing, the stamp can be wetted with the precursor solution and then be pressed onto the surface of the substrate using pneumatic pressure. As an alternative the stamp can be pressed directly into a thin film of the precursor on the substrate. This method is called nano imprint lithography (NIL), whereas the first one is known as micro contact printing (Fig. 1). The high resolution of the resulting structures and their low thickness are crucial for the preparation of transparent films.

Fig. 1: Scheme of the different soft lithography processes: nanoimprint lithography (left) and micro contact printing (right). Stamp (dark blue), precursor (orange) and substrate (light blue)

b)Preparation of precursors and imprinting

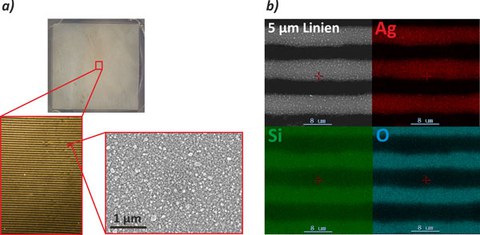

As inks new silver complexes and polymeric precursors could be prepared. One possible complex is the complex from silver with pyrrolidone ([Ag(Pyl)2NO3] (Pyl = 2-Pyrrolidon)). By adding tert-butylpyrrolidone to an ethanolic solution of this complex crystallization during printing could be avoided. After UV treatment and heating at 220°C either thin compact films or structures such as lines could be achieved after imprinting (Fig. 2).

Fig. 2: a) 1x1 cm2 line pattern of silver with SEM magnified image of the line (bottom, right) b) EDX mapping of the pattern

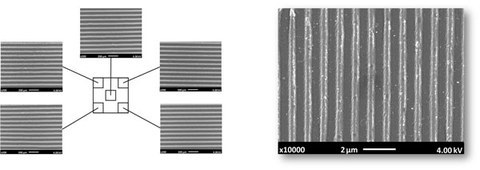

TCO films were prepared by the so-called Pechini approach. To an acidic solution of pre-polymerized ethylene glycol and citric acid the corresponding metal salts such as cadmium nitrate and tin citrate were added. During printing the solvent was evaporated by heating and simultaneously the polycondensation took place. By calcination at 700°C of a structured precursor of cadmium tin oxide (CTO) lines with a width down to 400 nm and a distance down to 600 nm could be prepared (Fig. 3). These structured CTO films have a transparency of around 80% while offering a good sheet resistance and could be used as transparent electrodes.

Fig. 3: SEM images of 20 µm line pattern (left) and 400 nm pattern (right)

c) Preparation of electroluminescence devices as proof of concept

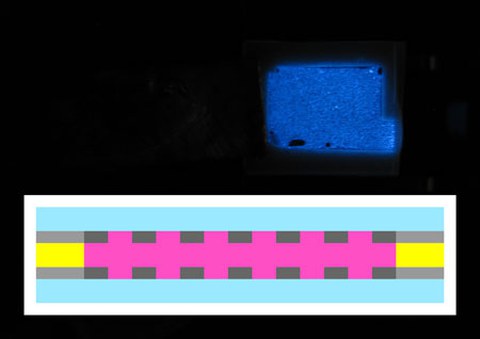

Patterned CTO electrodes were used for the fabrication of an electro-luminescence (EL) device. This EL device was prepared by pressing the EL paste - consisting of microcrystalline ZnS:Cu dissolved in different acrylates - between two electrodes. Afterwards the EL paste was cured using UV illumination. The resulting lamp was exited by applying an alternating current. The device shows a blue luminescence (Fig. 4).

Fig. 4: Photo of an EL device with CTO electrodes. Inset: Scheme of the EL-Device: glass substrate (blue), transparent electrode (dark grey), electrical contact (light grey), dielectric spacer (yellow) and EL phosphor (pink)