Apr 11, 2023

Huge demand for packaging made of thermal-insulated waste paper

Dagmar Möbius

If you’ve ever had to ship refrigerated food or medication, you’ll know all about this environmental dilemma – standard packaging made from polystyrene or plastic is notoriously difficult to recycle. It’s usually incinerated after use. But insulated material developed at TU Dresden, together with the Munich company easy2cool, is sustainable, award-winning, and increasingly popular.

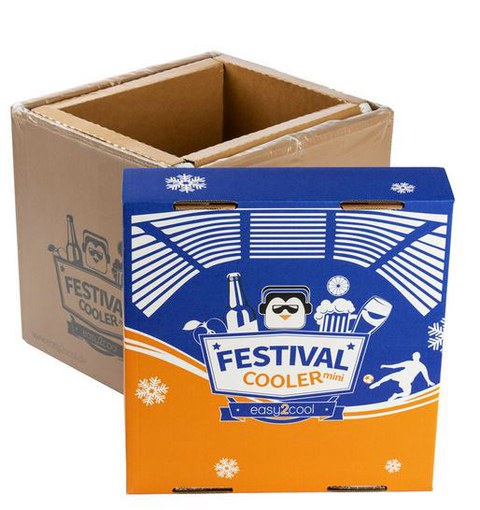

Popular for camping, festivals and leisure: the first ecological cooler made from recycled waste paper keeps food cool for four days without electricity.

Paperfloc is the end result of a collaborative project between TU Dresden and a company based in Munich. This novel ecological shipping insulation made of cellulose fibers was developed between April 2017 and July 2019. The Federal Ministry for Economic Affairs and Energy (now called the Federal Ministry for Economic Affairs and Climate Action) provided funding for the research and development as part of the Central Innovation Program for small and medium-sized enterprises (ZIM). This collaborative project between Saxony and Bavaria was distinguished as ZIM Success Story 195 in 2021.

The engineering graduate Thomas Schrinner from the Chair of Wood Technology and Fiber Materials Technology at TU Dresden coordinated the project at the time. First, waste paper was shredded and dried using a special process, resulting in fiber-based insulation material. What sounds simple in retrospect presented a major challenge for the researchers. “We needed to adapt the treatment process and develop special fiber composites so that the fiber mats had a particularly low density coupled with a sufficiently narrow pore size distribution, enabling the insulating properties to reach their optimum,” he explained. In other words: They were particularly remarkable for their low thermal conductivity. Cellulose has a higher heat storage capacity, meaning the sustainable fiber mats proved to be an even better insulating material than polystyrene. And there’s another benefit: Granted, a film layer was required to avoid direct contact with food – nevertheless paperfloc packaging is completely recyclable. The film makes up only 7 % of the whole packaging. The Paper Technology Research Group, to which Thomas Schrinner belongs, is researching alternatives to the film.

By the way: Manufacturing paperfloc requires just a fraction of the energy needed for polystyrene. Moreover, it emits 95 % less CO2. And cardboard can be recycled more than 25 times.

easy2cool, founded in 2014, is based in Munich. Managing Directors Sebastian Leicht and Marco Knobloch have resolved to do nothing less than “revolutionize the market for mobile refrigeration.” Their product portfolio not only includes solutions for food retailers – they also produce coolers made from paper that can keep drinks (and more) cool at festivals for up to 100 hours. The insulating bags and packaging can be ordered to suit your individual needs using the product configurator and can be recycled in the paper waste bin after use. The company reports that sustainable disposable packaging is growing in popularity – and not only for online food retailers, where refrigerated and frozen food products can be in transport for up to 48 hours.

Contact:

TU Dresden

Institute of Natural Materials Technology

Chair of Wood Technology and Fiber Materials Technology

Thomas Schrinner

Tel.: +49 351 463-38026

Email