Design model for slabs strengthened against impact

Table of contents

Project data

| Titel | Title Promotionsprojekt A5/III: Bemessungsmodell für Entwurf, Konstruktion und Berechnung von gegen Impakt verstärkten Platten als Teilprojekt des GRK 2250 | Doctoral projekt A5/III: Engineering model for calculation, design and construction of RC slabs strengthened against impact loading as part of the RTG 2250 Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) / GRK 2250 Zeitraum | Period 05/2023 – 04/2026 (3. Kohorte | 3rd cohort) Projektleiterin | Project manager apl. Prof. Dr.-Ing. Birgit Beckmann Bearbeiter | Contributor |

Report in the annual report 2023

Strengthening on every front

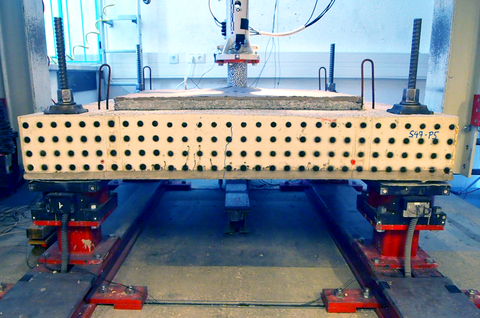

Impact test on a plate with a combination of damping system on top and rear side strengthening layer

In general, existing reinforced concrete structures only have limited resistance to impact loading. For this reason, the Research Training Group (RTG) 2250 “Mineral-bonded composites for enhanced structural impact safety” focused on developing solutions to optimize the behavior of components under impact loading.

In the first two cohorts of doctoral project A5, the research focus was on thin mineral-bonded strengthening layers applied to the rear side of reinforced concrete slabs which were designed both with and without shear reinforcement. In the current third cohort, the research approach is complemented by the consideration of an additional mineral-bonded damping layer applied to the impacted plate side. This research should result in an engineering model that describes the behavior of such reinforced concrete slabs.

At the end of the second cohort, a final series of tests was conducted in the institute’s drop tower facility to combine the research of several doctoral projects of RTG 2250. For this purpose, specimens with a rear side carbon-reinforced concrete layer (topic in projects A5/I and II) as well as plates with additional top side damping layer (topic in project A6/II) were tested. It was shown that the multi-layer damping system developed in project A6/II effectively reduced the impact load applied to the test specimen and completely prevented spalling on the top side. Fragmentation on the rear side due to scabbing was also reduced. In this respect, the strengthening layers showed their efficiency, as they were able to completely prevent the detachment of the fracture body due to their membrane effect. The combination of these two positive effects led to a significant reduction in plate damage in the velocity range tested and to the successful completion of the work of the second cohort.

In the third cohort, the system of plates strengthened on both sides is considered using a three-mass oscillator. Individual springs within the model describe the global bending properties, the local punching characteristics and the (damped) effect of the impactor. The behavior of the simplified dynamic model will be verified and improved by further tests.