Subproject A5

Fibre and Interphase Design with Polymers

Director

PD Dr.-Ing. habil. Edith

Mäder

Leibniz Institute of Polymer

Research Dresden

Staff

Dr.-Ing. Shang-Lin Gao

Dipl.-Chem. Rosemarie Plonka

Dipl.-Ing. Christina Scheffler

Dipl.-Ing. Theresa Förster

Aim

In the previous periods of the subproject A5 the preconditions for the spinning of alkali resistant glass fibres (AR-glass) have been established and the use for the manufacturing of tailored testing materials in the laboratory scale has been proved. The development of multifunctional sizings and compatible polymer coatings leads to an improved durability and a significantly enhanced performance of glass fibre reinforced concrete. The main topics of further research in the third period are focussed on theoretical and experimental works of interphase design as well as the adhesion improvement between reinforcing fibres and cementitious matrix with the aim of increased fracture energy particularly with regard to polymer coatings which are applied preferably on ARG spun at IPF. The systematical investigations for the development of adapted sizing/coating compositions are directed towards the selection of polymer film formers with combination of acidic and alkaline surfaces as well as the integration of nano fibres and nano particles in the sizing and coating, respectively. The knowledge obtained with polymer coatings on ARG will be transferred to carbon fibres.

Results

Interphase design with nano particles

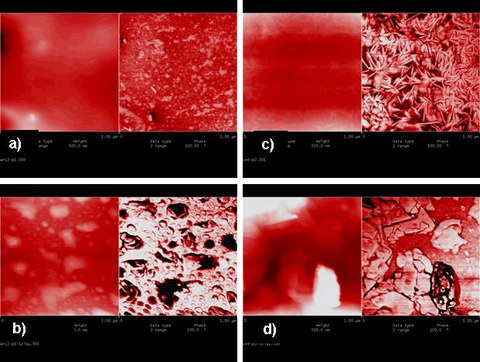

TIn the third period the surface morphology of the alkali

resistant glass fibres is varied selectively by the integration

of nano particles in the already successful applied sizings and

coatings. The investigation of the fibre surface by atomic

force microscopy (AFM) reveals changes of the nanoscale surface

structure caused by nanoclay particles depending on the used

styrene butadiene dispersion (Fig. 1). The surface of a glass

fibre spun at IPF and coated with a self-crosslinking

carboxylated styrene butadiene copolymer exhibits a smooth and

rather homogenously distributed coating showing very low

material inhomogeneities in the phase image (Fig. 1a). The same

coating with 1 wt% nanoclay (Fig. 1b) exhibits a somewhat

rougher surface with distributed clay platelets indicated in

the phase image and embedded in the coating. Fig. 1c shows a

fibres surface with a coating based on thermoplastic styrene

butadiene forming semi-crystalline structures. The surface

structure becomes more disturbed if nanoclay is added to this

coating (Fig. 5d). The nanoclay platelets tend to agglomerate

and are not well embedded in the coating, as can be seen by

increased roughness in the height image. In the case of

well-dispersed and embedded nanoclay particles a higher alkali

resistance was achieved. Otherwise, the surface properties of

the glass fibres are dominated by the hydrophilic surface

properties of the clay itself.

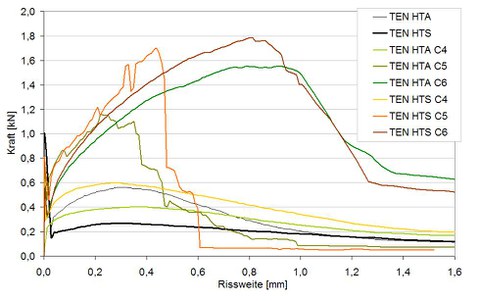

The performance of concrete composites with sized and coated

AR-glass filament yarns was determined by composite tensile

tests in cooperation with subproject A6 (Fig. 2);

additionally, the microstructure of the fibre matrix

interphase was studied by scanning electron microscopy

(SEM). The compatibility between the glass fibre sizing and

the polymer coating plays an important role to achieve a

high working capability of the concrete composite. For this

reason, AR-glass filament yarns spun at IPF with an adapted

sizing composition (IPF ARG 2) to a styrene butadiene

coating (IPF ARG 2 C2) show a significantly higher

performance compared to commercial AR-glass filament yarns

(VET ARG, sizing composition unknown) with the same coating

(VET ARG C2). The stepwise addition of nanoclay in the

coating leads to a desired displacement of the maximum fibre

pull-out force at lower crack widths. The investigation of

the microstructure indicates an increasing amount of

calcium-silicate-hydrate phases (CSH-phases) with increasing

content of nanoclay in the interphase. Hence, the intensive

interconnection between coated filaments and concrete matrix

enables an improved load transmission already at low crack

widths. It is assumed, that the clay particles serve as

nucleation points for the development of hydration

products.

Fig. 2: Force-crack width curves of composite tensile tests on concrete composites with glass filament yarns spun at IPF (IPF ARG 2) as well as commercial glass filament yarns (VET ARG) in the sized state and with different surface modification (C2: styrene-butadiene coating with addition of 1-5 weigth-% nanoclay)

Development of polymer coatings for carbon fibres

The knowledge of the previous works obtained with the development of polymer coating with AR-glass fibres were transferred on carbon rovings in the third working period. The development of epoxy based coatings appeared to be successful in particular. By the new developed coatings not only the rovings tensile strength was strongly increased (twice as much of Tenax HTS with coating based on epoxy esther), but also the performance of the concrete composite was significantly improved (Fig. 3). The occurrence of the force maximum at low or high crack widths can be varied by the stiffness of the epoxy coating as required.

Publications

2011

2010

- Brodowsky, H. ; Jenschke, W. ; Mäder, E. : Characterization of interphase properties by frequency-dependent cyclic loading of single fibre model composites. - Journal of Adhesion Science and Technology 24 (2010). - S. 237-253-doi:10.1163/016942409X12538812563236

- Brodowsky, H. ; Jenschke, W. ; Mäder, E. : Characterization of interphase properties: Microfatigue of single fibre model composites. - Composites / Part A 41 (2010). - S. 1579-1586 - doi:10.1016/j.compositesa.2010.07.006

- Gao, S.-L. ; Mäder, E. : Nano reinforcements in surface coatings and composite interphase. - in: INTECH new Book: "Nanocomposite Materials, Theory and Applications". - 2010. - im Druck ISBN 978-953-7619-X-X

- Mäder, E. : Nanostructured fibre sizings for interphase modification in composites. - in: 240th ACS National Meeting. - Boston, USA, 21.08.2010 - 26.08.2010.

- Förster, T. ; Plonka, R. ; Scheffler, C. ; Mäder, E. : Challenges for fibre and interphase design of basalt fibre reinforced concrete. - International Conference on Material Science and the 64th RILEM Annual Week. - Aachen, 06.09.2010 - 08.09.2010

- Förster, T. ; Plonka, R. ; Scheffler, C. ; Mäder, E. : Challenges for fibre and interphase design of basalt fibre reinforced concrete. - in: International RILEM Conference on Material Science : 1. 2nd ICTRC Textile Reinforced Concrete : Aachen, Germany, September 6-8, 2010. - Bagneux : RILEM Publ., 2010. - S. 57-66 (RILEM publications / Proceedings ; 75) ISBN 978-2-35158-106-3

2009

- Scheffler, C.; Gao, S.-L.; Plonka, R.; Mäder, E.; Hempel, S.; Butler, M.: Interphase modification of alkali-resistant glass fibres and carbon fibres for textile reinforced concrete II: Water adsorption and composite interphases. Composites Science and Technology 69 (2009) 905-912

- Scheffler, C.; Gao, S.-L.; Plonka, R.; Mäder, E.; Hempel, S.; Butler, M.; Mechtcheringe, V.: Interphase modification of alkali-resistant glass fibres and carbon fibres for textile reinforced concrete I: Fibre properties and durability. Composites Science and Technology 69 (2009) 531-538

- Scheffler, C. ; Förster, T. ; Mäder, E. ; Heinrich, G. ; Hempel, S. ; Mechtcherine, V. : Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by weibull distribution function. - Journal of Non-Crystalline Solids 355 (2009). - S. 2588-2595 - doi:10.1016/j.jnoncrysol.2009.09.018

- Scheffler, C. ; Gao, S.-L. ; Plonka, R. ; Mäder, E. ; Hempel, S. ; Butler, M. ; Mechtcherine, V. : Interphase modification of alkali-resistant glass fibres and carbon fibres for textile reinforced concrete. I: Fibre properties and durability. - Composites Science and Technology 69 (2009). - S. 31-538 doi:10.1016/j.compscitech.2008.11.027

- Scheffler, C. ; Gao, S.-L. ; Plonka, R. ; Mäder, E. ; Hempel, S. ; Butler, M. ; Mechtcherine, V. : Interphase modification of alkali-resistant glass fibres and carbon fibres for textile reinforced concrete II: Water adsorption and composite interphases. - Composites Science and Technology 69 (2009). - S. 905-912 - doi:10.1016/j.compscitech.2008.12.020

- Mäder, E. ; Gao, S.-L. ; Rausch, J. ; Zhuang, R.-C. ; Zhang, J. ; Liu, J. ; Scheffler, C. ; Plonka, R. : Multifunctional effects by nanostructured interphases. - DFC-10 Deformation and Fracture of Composites Conference. - Sheffield, UK, 15.04.2009 - 17.04.2009

- Scheffler, C. ; Förster, T. ; Mäder, E. : Beschleunigte Alterung von Glasfasern in alkalischen Lösungen: Einflüsse auf die mechanischen Eigenschaften. - 4. Kolloquium zu textilbewehrten Tragwerken (CTRS4) und zur 1. Anwendertagung. - Dresden, 03.06.2009 - 05.06.2009

- Scheffler, C. ; Förster, T. ; Mäder, E. : Beschleunigte Alterung von Glasfasern in alkalischen Lösungen: Einflüsse auf die mechanischen Eigenschaften. - in: Textilbeton - Theorie und Praxis : Tagungsband zum 4. Kolloquium zu textilbewehrten Tragwerken (CTRS4) und zur 1. Anwendertagung ; Dresden, 3.6.2009 - 5.6.2009 / [Technische Universität Dresden, Sonderforschungsbereich 528; Deutsches Zentrum Textilbeton.] Hrsg. von Manfred Curbach - Dresden : Technische Universität, 2009. - S. 63-74 ISBN 978-3-86780-122-5

2008

- Gao, S.-L.; Mäder, E.; Plonka, R.: Nanocomposite coatings for healing surface defects of glass fibers and improving interfacial adhesion. In: Composites and Science Technology 68 (2008) 2892-2901 – doi:10.1016/j.compscitech.2007.10.009

- Gao, S.-L. ; Mäder, E. ; Plonka, R. : Nanocomposite coatings for healing surface defects of glass fibers and improving interfacial adhesion. - Composites Science and Technology 68 (2008). - 2892-2901- doi:10.1016/j.compscitech.2007.10.009

- Brodowsky, H. ; Mäder, E. : Cyclic loading of the interphase in single fibre model composites. - in: ECCM 13, 13th European Conference on Composite Materials. - Stockholm, 02.06.2008 - 05.06.2008

- Brodowsky, H. ; Mäder, E. : Cyclic loading of the interphase in single fibre model composites. - ECCM 13, 13th European Conference on Composite Materials. - Stockholm, 02.06.2008 - 05.06.2008

- Mäder, E. : Multifunctional effects by nanostructured interphases. - ACCM-6, The 6th Asia-Australasian conference on Composite Materials. - Kumamoto, Kyushu, Japan, 23.09.2008 - 26.09.2008

- Mäder, E. ; Gao, S.-L. ; Rausch, J. ; Scheffler, C. ; Plonka, R. : Nanostructured interphases: Multifunctional effects from filament to component. - 2. Aachen-Dresden International Textile Conference. - Dresden, 04.12.2008 - 05.12.2008

- Mäder, E. : Multifunctional effects by nanostructured interphases. - in: Progress of Composites 2008 in Asia and Australia, Proceedings of the Sixth Asian-Australasian Conference on Composite Materials (ACCM-6). - 2008. - S. 64-67 ISBN 978-4-901381-32-1

- Mäder, E. ; Gao, S.-L. ; Rausch, J. ; Scheffler, C. ; Plonka, R. : Nanostructured interphases: Multifunctional effects from filament to component. - in: 2. Aachen-Dresden International Textile Conference, 4./5.12.2008. - Aachen : DWI, 2008. - S. 104-105 ISBN 1867-6405

- Scheffler, C. ; Plonka, R. ; Mäder, E. : Time dependent changes of glass/cement interphases influenced by nanostructured polymeric coatings. - in: 2. Aachen-Dresden International Textile Conference , 4./5.12.2008. - Aachen : DWI, 2008. - 8 Seiten ISBN 1867-6405

2007

- Gao, S.-L.; Mäder, E.; Plonka, R.: Nanostructured coatings of glass fibers: Improvement of alkali resistance and mechanical properties. In: Acta Materialia 55 (2007) S. 1043-1052

- Gao, S.-L.; Mäder, E.; Plonka, R.:Surface Defects Repairing by Polymer Coating with Low Fraction of Nano-reinforcements. In: Key Engineering Materials 334-335 (2007) 757-760

- Mäder, E.; Gao, S.-L.; Plonka, R.: Static and dynamic properties of single and multi-fiber/epoxy composites modified by sizings. In: Composites and Science Technology 67 (2007) S. 1105-1115

- Mäder, E.; Plonka, R.; Gao, S.-L.; Rothe, C.: Beschichtung in verstärkten Verbundwerkstoffen. Offenlegungsschrift DE 10 2005 048 190 A1 2007.04.05.

- Mäder, E.; Gao, S.-L.; Plonka, R.; Melcher, S.; Rausch, J.: Online Oberflächenmodifizierung und Nanostrukturierung von Verstärkungsfasern. In: G. Blasek (Hrsg.): 15. Tagungsband Neues Dresdner Vakuumtechnisches Kolloquium: Beschichtung und Modifizierung von Kunststoffoberflächen, Dresden, 17.-18.10.2007.. ISBN 978-3-00-022604-5, S. 39-47

- Gao, S.-L.; Mäder, E.; Plonka, R.: Healing surface defects by nanocomposite coating. In: K. Kageyama et al. (Hrsg.): Proceedings 16th Int. Conf. On Composite Materials ICCM, Kyoto, Japan, July 8-13, 2007. CD-ROM, 1-10, ISBN 978-4-931136-05-2

- Mäder, E.; Gao, S.-L.; Plonka, R.: Nanostructured interphases of glass fibre / cement composites. In: Proceedings COMAT, 2007. ISBN 978-85-285-0111-7, CS-04, S. 1-6

- Mäder, E.: Interphases in Composites – Design, Characterization and Composites Performance. In: Int. Conf. On Structural Analysis of Advanced Materials (ICSAM), Patras, Greece, September 2-6, 2007.

- Mäder, E.: Grenzschichten in Composites – Modifizierung, Charakterisierung, Design. Fraunhofer IZM, Teltow-Seehof, 27.8.2007

2006

- Zhandarov, S.; Gorbatkina, Yu. A.; Mäder, E.: Adhesional pressure as a criterion for interfacial failure in fibrous microcomposites and its determination using a microbond test. In: Composites and Science Technology 66 (2006) S. 2610-2628

- Gao, S.-L.; Mäder, E.; Plonka, R.: Polymer coating with low fraction of nanoreinforcements: Large enhancement of mechanicsl properties and environmental resistance of glass fiber. In: Nanotech 2006, Boston, USA, 7.-11.5.2006.

- Gao, S.-L.; Mäder, E.; Plonka, R.: Surface Defects Repairing by Polymer Coating with Low Fraction of Nano-reinforcements. In: The Fifth Asian-Australasian Conference on Composite Materials (ACCM-5), Hongkong, 27.-30.11.2006.

- Gao, S.-L.; Mäder, E.; Plonka, R.; Scheffler, C.: Nanostructured coating for functionalising surface properties of traditional materials. In: 7. IPF-Kolloquium, Innovative Beschichtungsstoffe und -technologien, Dresden, 8.-9.11.2006.

- Mäder, E.; Gao, S.-L.; Plonka, R.: Nanostructuring of reinforcement surfaces and interphases in composites. In: ICOSECS 5, International Conference of the Chemical Society of the South-East European Countries-Ohrid, Macedonia, 10.-14.9.2006.

- Rothe, C.; Gao, S.-L.;Plonka, R.; Mäder, E.: Nano surface structuring of alkaliresistant glass fibres for multifunctional effects. In: Josef Hegger (Hrsg.): Proceedings of the 1st International RILEM Conference Textile Reinforced Concrete, ICTRC, held at the RWTH Aachen University and organized by the RILEM Technical Committee 201-TRC and the Instituites of Structural Concrete and Building Materials Resarch, Aachen, Germany ; Aachen, September 6/7, 2006. Bagneux : RILEM Publications, 2006, pp. 67-76, (RILEM proceedings : PRO ; 50), ISBN 2-912143-97-7

2005

- Zhandarov, S.; Mäder, E.: Peak force as function of the embedded length: Comparison of the microbond and pull-out tests. In: Journal of Adhesion Science and Technology 19 (2005) S. 817-856

- Zhandarov, S.; Pisanova, E.; Mäder, E.: Is there any contradiction between the stress and energy failure criteria in micromechanical tests? Pt. III. Experimental observation of crack propagation in the microbond test. In: Journal of Adhesion Science and Technology 19 (2005) 679-704

- Zhandarov, S.; Mäder, E.: Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. In: Compos. Sci. Technol. 65 (2005) 149-160

- Ehrentraut, W.; Plonka, R.; Mäder, E.; Gao, S.-L.: Pilotanlage zum Erspinnen alkaliresistenter Glasfasern. In: Technische Textilien/Technical Textiles 48 (2005) 22-24, E23-E25

- Plonka, R.; Rothe, C.; Mäder, E.: Beschichtete alkaliresistente Glasfäden und Hybridgarne als Bewehrung in Beton. In: Technische Textilien/Technical Textiles 48 (2005) 150-152, E122-E124

- Gao, S.-L.; Mäder, E.; Plonka, R.: Surface flaw sensitivity of glass fibres with carbon nanotube/polymer coating. In: Verijenko, V.E.; Adali, S.; Morozov, E.; von Klemperer C.J. (edts.): Proc. 15th Int. Conf. On Composite Materials ICCM´15, 27 June-1 July, Durban, South Africa, CD-ROM, 1-10, ISBN:1-86840-589-3.

- Mäder, E. Gao, S.-L.; Plonka, R.: Alkali-resistant nano-coatings for glass fibres in a cementitious matrix. In: Verijenko, V.E.; Adali, S.; Morozov, E.; von Klemperer C.J. (edts.): Proc. Extended Abstracts 15th Int. Conf. On Composite Materials ICCM´15, 27 June-1 July, Durban, South Africa, 2005 Univ. of KwaZulu-Natal, 387-388, ISBN:1-86840-587-7.

- Mäder, E.; Rothe C.: Erspinnen alkaliresistenter Glasfasern und deren effiziente Oberflächenmodifizierung. In: Poster Int. Techtextil-Symp., 7.-9.06., 2005, Frankfurt.

- Mäder, E.; Gao, S.-L.; Plonka, R.; Liu, J.: Nano-coatings on High Performance Fibres - Feasibility of Achieving Revolutionary Composite Properties? In: Proc. Int. Conf. On Interfaces & Interphases in Multicomponent Materials, 1-2, September 12-14, 2005, Lyon, France.

- Rothe, C.; Gao, S.-L.; Plonka, R.; Mäder, E.: Alkali-Resistant Nano Coatings for Interpase Design in Glass Fibre Reinforced Concrete. Proc. Int. Conf. On Interfaces & Interphases in Multicomponent Materials, 1-2, September 12-14, 2005, Lyon, France.

- Mäder, E.: Nanostructured surfaces and interphases in polymer matrix composites. In: Materials´ Days, Rostock 2005, Interface Effects in Functional Materials, May 23-24, 2005.

- Rothe, C.; Gao, S.-L.; Plonka, R.; Mäder, E.: New Alkali Resistant Glass Fibres for Interphase Design in Textile Reinforced Concrete. Proc. Int. Techtextil-Symp., 7.-9.6.2005, Frankfurt.

- Plonka, R.; Mäder, E.; Rothe, C.; Köckritz, U.; Waldmann, M.; Klug, P.: Effective Reinforcement of Concrete by On-line Polymer Coating. / Effiziente textile Bewehrungen für den Beton durch Online-Polymerbeschichtung. In: Technical Textiles / Technische Textilien 48 (2005) S. 205-207, E161-E163.

2004

- Schorn, H.; Raupach, M.; Brameshuber, W.; Höcker, H.; Mäder, E.; Arnold, B.J.A.; Brockmann, T.; Hempel, R.; Orlowsky, J.; Plonka, R.:Betontechnologie und Dauerhaftigkeit von glasfaserbewehrten Bauteilen. Beton- und Stahlbetonbau 99 (2004), H. 6, 444-451 – doi:10.1002/best.200490114

- Plonka, R.; Mäder, E.; Gao, S.-L.; Bellmann, C.; Dutschk, V.; Zhandarov, S.: Adhesion in epoxy/glass fibre composites influenced by aging effects on sizings. In: Composites A 35 (2004) 1207-1216

- Gao, S.-L.; Mäder, E.; Plonka, R.: Coatings for Glass Fibers in a Cementitious Matrix. Acta Materialia 52 (2004) /16, 4745-4755

- Mäder, E.; Gao, S.-L.; Plonka, R.: Enhancing the properties of composites by controlling their interphase parameters. In: Advanced Engineering Materials 6 (2004) 3, 147-150

- Gao, S.-L.; Mäder, E.; Zhandarov, S.: Carbon Fibres and Composites with Epoxy Resins: Topography, Fractography and Interphases. In: Carbon 42 (2004) 515-529

- Zhandarov, S.; Mäder, E.: Determination of interfacial parameters in fiber-polymer systems from a pull-out test data using a bilinear bond law. In: Composite Interfaces 11 (2004) 5-6, 361-392

- Mäder, E.; Hübner, T.; Gao, S.-L.; Plonka, R.; Häßler, R.: Static and dynamic properties of single and multi-fiber/epoxy composites. Acta Materialia (2004) - submitted

- Mäder, E.; Gao, S.-L.; Plonka, R.; Ehrentraut, W.: Neue Aspekte der Faser- und Grenzschichtgestaltung in textilbewehrtem Beton. In: 7. Dresdner Texiltagung 16.–17. 06.2004

- Mäder, E.: Eigenschaftsverbesserung von Beton durch Einsatz von Verstärkungsfasern. In: Workshop ”Erweiterter Einsatz von Polymerbeton“, 26. 03. 2004, POLYKUM e.V., Halle

- Mäder, E.; Plonka, R.; Gao, S.-L.: Werkstoffeigenschaften langfaserverstärkter Thermoplaste beeinflusst durch Grenzflächen. In: 10. Nationales Symposium SAMPE Deutschland e.V., Dresden, 12. –13. 02. 2004. Tagungsband, S. 1-11

- Gao, S.-L.; Mäder, E.; Plonka, R.: Protective alkali-resistant Interphase for Glass Fibres in a Cementitious Matrix. In: Proceedings 11th European Conf. On Composite Materials (ECCM-11), 31. 05. –03.06.2004, Rhodes, Greece

- Zhandarov, S.; Yurkevich, O. R.; Mäder, E.: The accuracy of interfacial adhesion parameters determination in the single fiber pull-out test: debond force and maximum force. In: 12th Annual POLYCHAR World Forum on Advanced Materials. - Guimaräes, Portugal, 06.-09.01.2004

- Mäder, E.; Plonka, R.; Schiekel, M.; Hempel, R.: Coatings on alkali-resistant glass fibres for the improvement of concrete. J. Industrial Textiles 33 (2004) 191-207

2003

- Gao, S.-L.; Mäder, E.; Abdkader, A.; Offermann, P.: Environmental resistance and mechanical performance of alkali-resistant glass fibers with surface sizings. In: J. Non-Crystalline Solids 325 (2003) S. 230-241

- Gao, S.-L.; Mäder, E.; Abdkader, A.; Offermann, P.: Sizings on Alkali-Resistant Glas Fibers: Enviromental Effects on Mechanical Properties. In: Langmuir 19 (2003) 2496–2506

- Mäder, E.; Plonka, R.; Schiekel, M.; Hempel, R.: Neue Möglichkeiten: Die Beschichtung alkaliresistenter Glasfasern zur Verbesserung von Beton. Tagungsmaterialien 12. Internationales Techtextil-Symposium Frankfurt/M. Frankfurt/M., 9.4.2003, Vortrag 4.12

- Mäder, E.; Gao, S.-L.; Plonka, R.: Coatings on Alkali-Resistant Glass Fibres. Conf. on Interfaces and Interphases in Multicomponent Materials, Oct. 5-8, 2003, Balatonfüred

- Mäder, E.; Plonka, R.; Gao, S.-L.: Coatings for Fibre and Interphase Modification in a Cementitious Matrix. M. Curbach (Edt.), Proc. of the 2nd Colloquium on Textile Reinforced Structures (CTRS2), 29. 9. - 1. 10. 2003, Dresden. pp. 121-132

- Zhandarov, S.; Mäder, E.: Indirect estimation of polymer/fiber bond strength and interfacial friction from maximum load values recorded in the microbond and pull-out tests. Part II: Critical energy release rate. Journal of Adhesion Science and Technology 17 (2003) 7, S. 967-980 – doi:10.1163/156856103322112879

- Zhandarov, S.; Mäder, E.: Characterization of Fiber/Matrix Interface Properties: Applicability of Different Tests, Approaches and Parameters. M. Curbach (Edt.), Proc. of the 2nd Colloquium on Textile Reinforced Structures (CTRS2), 29. 9. - 1. 10. 2003, Dresden. pp. 101-120

- Gao, S.-L.; Mäder, E.; Plonka, R.: Mapping Composite Interphase Properties – Elasticity and Electricity. In: Conf. on Interfaces and Interphases in Multicomponent Materials, Oct. 5-8, 2003, Balatonfüred.

- De Lange, P. J.; Akker, P. G.; Mäder, E.; Zhandarov, S.; Young, R. J.: Strength of interphase of Twaron aramid reinforced composites in relation to the fibre finish formulation. In: Conf. on Interfaces and Interphases in Multicomponent Materials, Oct. 5-8, 2003, Balatonfüred.

2002

- Gao, S. L.; Mäder, E.; Abdkader, A.; Offermann, P.: Influences of Surface Sizings on Mechanical Properties of Alkali-resistant Glass Fibers. Konferenz-Einzelbericht: Schmelzspinnen von Polymeren und Glas in der Polymerforschung, Melt Spinning of Polymers and Glass in Polymer Research, Symposium, Tagungsband / Proceedings, Inst. f. Polymerforschung Dresden, 13.-14. Mai, 2002, (2002) Seite 259-261

- Gao, S.; Mäder, E.: Characterisation of interphase nanoscale property variations in glass fibre reinforced polypropylene and epoxy resin composites. Composites / Part A 33 (2002) 559-576

- Zhandarov, S.; Mäder, E.; Yurkevich, O. R.: Indirect estimation of polymer/fiber bond strength and interfacial friction from maximum load values recorded in the microbond and pull-out tests. Part I: Local bond strength. Journal of Adhesion Science and Technology 16 (2002) 9, S. 1171-1200

2001

- Gao, S.; Mäder, E.: Einfluss der Topographie und der chemischen Natur von Schlichten auf die Grenzflächenwechselwirkung in glasfaserverstärktem Beton. Seminar des SFB 528 der Technischen Universität Dresden (Textile Bewehrungen zur bautechnischen Verstärkung und Instandsetzung), 15. 01. 2001, TU Dresden

- Mäder, E.; Gao, S.: Haftungsverbesserung in Verbundwerkstoffen durch modifizierte Grenzschichten - Effekt der Topographie und der chemischen Natur der Oberflächenmodifizierung auf die Faser-Matrix-Wechselwirkung in glasfaserverstärktem Beton. Vortrag zum Silikattechnischen Seminar im Rahmen des SFB 285 "Partikelwechselwirkung" der TU Bergakademie am 12. Juni 2001, Freiberg

- Mäder, E.; Gao, S.: Prospect of nanoscale interphase evaluation to predict composite properties. J. Adh. Sci. Technol. 15 (2001) 1015-1037

- Zinck, P.; Mäder, E.; Gerard, J. F.: Role of silane coupling agent and polymeric film former for tailoring glass fiber sizings from tensile strength measurements. J. Mater. Sci. 36 (2001) S. 5245-5252