Improved scheduling of Mobile Robot charging operations

Project coordination & management

Herr Prof. Dr. rer. pol. habil. Thorsten Claus;

Herr Prof. Dr. rer. pol. Enrico Teich (Berufsakademie Sachsen - Staatliche Studienakademie Dresden)

Project implementation

Herr Dipl.-Ing. Maximilian Dilefeld

Period:

01.04.2023 bis 31.03.2026

Short description:

Mobile robots have been established as an important tool for intralogistics systems. A key argument for their implementation is their flexibility with regard to a fluctuating transport demand as well as adaptability to changing conditions.

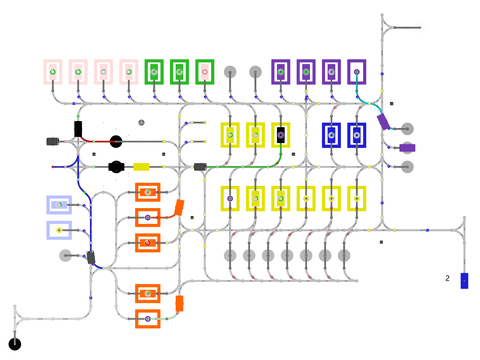

To control AGVs (Automated Guided Vehicle) and AMRs (Autonomous Mobile Robot), several planning problems must be solved in the master control system (fleet manager). Material flow control (often external e.g. MES) must select sources and sinks for linking transport orders. Orders, which in the case of AMRs can go beyond pure product transport, must be collected and sorted in order management. Vehicle dispatching checks which vehicles can execute an order and must select the most appropriate one. Vehicle conditions are monitored and loading operations as well as trips to waiting positions when no orders are available must be planned independently. In order processing, orders are broken down into smaller tasks that can be sent to and processed by the vehicles. An essential part of the order processing is the navigation to select the optimal route and avoid vehicle encounters.

As these vehicles are battery-powered, the availability of the transport system is largely dependent on the charging states of the individual mobile robots. The project deals with the improvement of charging strategies for these transport systems by considering the charging state of in the planning areas of the fleet manager. The goal of the project is a more efficient use of the resource electricity as well as consideration of the state of charge in the planning in order to achieve a better availability especially in scenarios with large fluctuations in utilization.

Specifically, strategies are implemented and validated in a simulation solution designed by DUALIS GmbH IT Solution using the 3D simulation platform Visual Components. The evaluation of the implemented strategies is carried out on a practical application of a post-processing line for painted vehicle bodies.

Partners & supporters: