DFG Project Cutting of Natural materials

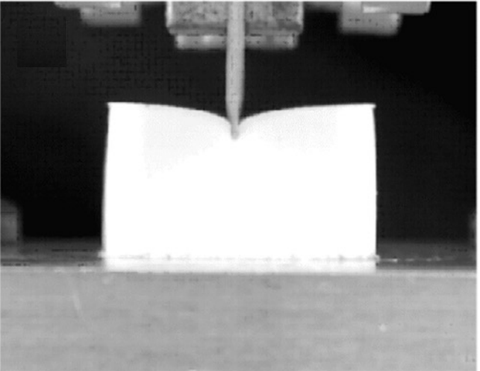

Cutting of Natural materials (Schuldt 2016)

Deformation and cutting behaviour of natural materials often strongly depend on the rate of deformation.

This phenomenon can have a large influence on the manufacturing process of foods, e.g. the cutting of cheese. On the one hand, a significant inelastic deformation precedes fracture for slow cutting. This can lead to rough crack surfaces. On the other hand, brittle fracture which occurs when the cutting velocity is large may come along with the creation of material splitters. These may essentially disturb the manufacturing process. Thus, the prediction of the velocity dependent cutting behaviour is of large interest.

In this project, a crack phase field model which accounts for the rate dependent behaviour of natural materials is developed. The main focus is set on the ductile to brittle failure mode transition.

In order to get deeper insight into the mechanisms arising during cutting, a model material which shows a behaviour that is representative for common foods is investigated experimentally. Therefore, a cooperation with the Chair of Food Engineering of TU Dresden has been established.

Cooperations

Project staff

© TUD/NEFM

© TUD/NEFM

Dipl.-Ing. Franz Dammaß

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 356 George-Bähr-Straße 3c

01069 Dresden

© TUD/NEFM

© TUD/NEFM

Professor for Computational and Experimental Solid Mechanics

NameProf. Dr.-Ing. habil. Markus Kästner

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 353 George-Bähr-Straße 3c

01069 Dresden