08.06.2023

DigiTain – Digitalization for Sustainability

Teilnehmer des Projekt-KickOff

Projektlogo DigiTain

Das Forschungsprojekt DigiTain (Digitalization for Sustainability) zur volldigitalen Produktentwicklung nachhaltiger Elektroantriebsarchitekturen nimmt Fahrt auf.

Bestehend aus 26 geförderten und 2 assoziierten Partnern aus Industrie und Wissenschaft startete das Forschungsprojekt DigiTain am 01.01.2023 mit einer Projektlaufzeit von insgesamt 36 Monaten. In DigiTain werden Prozesse, Methoden und Modelle zur volldigitalen Produktentwicklung und Zertifizierung nachhaltiger elektrischer Antriebsarchitekturen entwickelt und anhand eines Technologieträgers erprobt.

Das Projekt wird im Rahmen des Konjunkturpakets, Ziffer 35c im Modul b „Neue, innovative Produkte als Schlüssel für Fahrzeuge und Mobilität der Zukunft“ von der Bundesregierung und der Europäischen Union gefördert. „Insbesondere der ganzheitliche Ansatz, der mehrere technologische Innovationen integriert, die wertschöpfungsübergreifende Vernetzung der Partner und ihrer Fachexpertise sowie das damit verbundene Transferpotenzial in Industrie und Gesellschaft machen Digitain zu einem Leuchtturmprojekt unseres Fachprogramms“, so Stefan Heidemann vom BMWK.

Die Projektträgerschaft für DigiTain hat die TÜV Rheinland Consulting GmbH übernommen.

Zum Auftakttreffen am 31.01.2023 trafen sich rund 100 Teilnehmerinnen und Teilnehmer des Konsortiums größtenteils vor Ort beim Konsortialführer Mercedes-Benz AG in Sindelfingen, teilweise aber auch virtuell. Neben der Vorstellung der Arbeitspakete und der Planung der Zusammenarbeit bot das Auftakttreffen den Partnern die Möglichkeit zum übergreifenden Austausch über die geplanten Forschungsinhalte.

Projektpartner DigiTain

Digitalisierung der Fahrzeugentwicklung und Zertifizierung für nachhaltige Antriebsarchitekturen von morgen

Ökologische und ökonomische Nachhaltigkeitskriterien bei der Entwicklung von Fahrzeug- und Antriebsarchitekturen gewinnen in Politik, Gesellschaft und Industrie zunehmend an Bedeutung. Die technisch-ökonomischen Kriterien der klassischen Produktentwicklung und -optimierung mit einer ökologischen Produktbewertung erst in der späten Phase der Produktentstehung sind daher nicht mehr ausreichend und zeitgemäß.

Die entwicklungsbegleitende Nachhaltigkeitsbewertung während des Produktentstehungsprozesses stellt die Entwickler derzeit vor große Herausforderungen, da geeignete digitale Prozesse, Methoden und Werkzeuge zur entwicklungsbegleitenden ökologischen Optimierung des Gesamtfahrzeugs einschließlich der Antriebskomponenten nicht verfügbar sind. Zudem fehlen verbindliche Standards für die vollständig digitale Produktentwicklung und -bewertung, so dass für die Zertifizierung noch eine Vielzahl experimenteller Absicherungstests erforderlich ist.

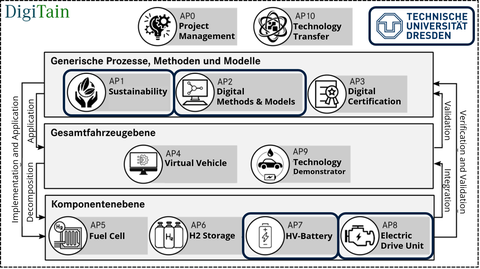

DigiTain Projektstruktur

In DigiTain werden daher genau solche Prozesse, Methoden und Modelle zur volldigitalen Produktentwicklung und Zertifizierung von elektrischen Antriebsarchitekturen entwickelt, die von Beginn an nicht nur auf die Entwicklung wettbewerbsfähiger Antriebe abzielen, sondern auch ökologische und ökonomische Nachhaltigkeitskriterien einbeziehen. Ziel ist eine ganzheitliche Entwicklung von Gesamtfahrzeug und Antriebsarchitektur unter Berücksichtigung aller produktinduzierten Bereiche. Die Anwendung und Validierung des nachhaltigkeitsorientierten Entwicklungsprozesses (NEP) sowie der entwickelten generischen Methoden und Modelle erfolgt am Beispiel der Entwicklung und Optimierung eines Elektrofahrzeugs mit hybrider Antriebsstrategie aus Brennstoffzellenaggregat und HV-Batteriesystem.

TU Dresden in Projekt DigiTain

Zur Umsetzung modernster digitaler und nachhaltiger Entwicklungsansätze arbeitet das Institut für Leichtbau und Kunststofftechnik (ILK), vertreten durch die Professur für Funktionsintegrativen Leichtbau [Prof. Dr.-Ing. Niels Modler], gemeinsam mit der Professur für Virtuelle Produktentwicklung (VPE) [Prof. Dr.-Ing. Kristin Paetzold-Byhain] gezielt an Lösungen für nachhaltige Antriebsarchitekturen. Die TU Dresden ist an folgenden Arbeitspaketen beteiligt:

AP1: Nachhaltigkeit

Die TU Dresden konzentriert sich dabei auf die Weiterentwicklung des nachhaltigkeitsorientierten Produktentstehungsprozesses (NEP) als generisches Framework zur Integration von Nachhaltigkeitsaspekten in die Produktentwicklung. Die Schwerpunkte liegen dabei u.a. auf der Ökobilanzierung und Kreislaufmodellierung unter Verwendung von Ansätzen des Model Based Systems Engineering (MBSE). Durch den intensiven Austausch mit allen Partnern wird das NEP übergreifend für die Entwicklung aller Hardwaresysteme anwendbar.

AP2: Digitale Methoden und Modelle

Die Prozessschritte, die bei der Produktentwicklung hinsichtlich Design, Analyse, Validierung und Verifizierung durchlaufen werden, müssen unter Berücksichtigung einer Vielzahl unterschiedlicher Inputdaten miteinander verknüpft und strukturiert werden, um einen nachhaltigen Nutzen der Daten im Sinne des Produkt-Lifecycle-Managements zu gewährleisten. In Zusammenarbeit mit der XPLM Solution GmbH Dresden entwickelt die TU Dresden in diesem Arbeitspaket eine anwendbare, digitale Lösung zum Datenaustausch und zur Datenverwaltung für die Prozesskette und die verknüpfte Modellbildung innerhalb des Produktentwicklungsprozesses, wobei der Fokus insbesondere auf den Berechnungsprozessketten zur Auslegung hochdynamisch belasteter Leichtbaustrukturen liegt. Diese soll ein effizienteres Arbeiten innerhalb der CAE-basierten Fahrzeugauslegung in diesem sowie zukünftigen Projekten ermöglichen.

AP7: HV-Batteriesystem

Die TU Dresden entwickelt nachhaltige und kreislauffähige Batteriegehäuse in Hybridbauweisen. Ziel ist es, die besten Eigenschaften von FKV, Metallen und Kunststoffen zu kombinieren und so Strukturen mit minimalem ökologischem Fußabdruck bei voller Fahrzeugsicherheit zu gewährleisten. Im Gegensatz zu vielen bestehenden FKV und Kunststoff-Batteriegehäusen werden hier ausschließlich thermoplastische Polymersysteme eingesetzt. Damit sollen neue Wege in der Kreislaufführung beschritten werden.

AP8: Elektrische Achse

In diesem Arbeitspaket arbeitet die TU Dresden an der Entwicklung axial skalierbarer Systemarchitekturen elektrischer Achsen unter Verwendung von FKV-Rotorwellen und Gehäusekomponenten in Hybridbauweise. Ziel der skalierbaren Architektur ist die Bereitstellung einer Vielzahl von Achskonfigurationen mit einem Minimum an Entwicklungsaufwand sowie einer Reduktion der Anlagentechnik zur Herstellung der Systeme. Dadurch werden Ressourcen in Entwicklung und Produktion eingespart.

Förderhinweis DigiTain

Projektleitung TU Dresden:

© Christian Hüller

© Christian Hüller

Professur für Funktionsintegrativen Leichtbau

NameProf. Dr.-Ing. Niels Modler

Eine verschlüsselte E-Mail über das SecureMail-Portal versenden (nur für TUD-externe Personen).

Institut für Leichtbau und Kunststofftechnik

Besucheradresse:

DÜR, Etage 0, Raum 69 Holbeinstr. 3

01307 Dresden

Deutschland

Projektverantwortlicher TU Dresden:

© keine Copyrights

© keine Copyrights

Dipl.-Ing. Paul Hoffeins

Leiter Leichtbauweisen

Eine verschlüsselte E-Mail über das SecureMail-Portal versenden (nur für TUD-externe Personen).

Institut für Leichtbau und Kunststofftechnik

Besucheradresse:

DÜR, Etage 0, Raum 53 Holbeinstr. 3

01307 Dresden

Deutschland