18.01.2021

Effizienzsteigerung durch digitale Produktentwicklung

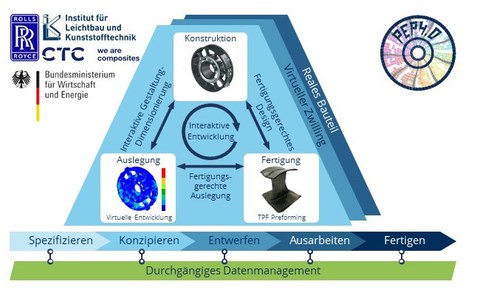

Interaktiver Entwicklungsprozess mit den Einzeldisziplinen Konstruktion, Auslegung und Fertigung (oben) entlang der Phasen von der Spezifikation der Anforderungen bis zur Fertigung (unten)

Das Institut für Leichtbau und Kunststofftechnik (ILK) der TU Dresden erforscht gemeinsam mit dem Projektpartner Rolls-Royce Deutschland Ltd. & Co.KG und der CTC GmbH im Projekt „Digital synchronisierte Entwicklungsarchitektur für den Produktentstehungsprozess – PEP4.0“ Methoden und Vorgehensweisen zur Verbesserung von konstruktiven Entwicklungsprozessen für komplexe Leichtbaustrukturen am Beispiel eines Triebwerks-Zwischengehäuses.

Ziel des Projektes ist es, neue Technologien zur Umsetzung hybrider Metall-Faserverbund-Bauweisen zur Anwendung zu bringen und dabei eine deutliche Effizienzsteigerung hinsichtlich kürzerer Entwicklungszeit und geringerem Risiko zu erreichen.

Grundlage dafür wird ein digital verknüpfter Produktentstehungsprozess (PEP4.0) sein, welcher die Methoden, Modelle und Daten (MMD) der Einzeldisziplinen Konstruktion, Auslegung und Fertigung zu einer vernetzen Entwicklungsstruktur mit definierten Schnittstellen und einer durchgängigen Datenverarbeitung und -analyse verbindet.

Eine umfassend vernetzte Entwicklungsstruktur bietet den Vorteil unmittelbar verfügbarer Daten, die für die Entwicklung notwendig sind. Diese Daten entsprechen den virtuellen und realen Gegebenheiten. Interagierende Schlüsselparameter entlang der gesamten Produktentstehungskette und ihre Auswirkungen auf die Produkteigenschaften werden sichtbar.

Das Projekt wird im Rahmen des fünften Luftfahrtforschungsprogramms (LuFo) des Bundesministeriums für Wirtschaft und Energie BMWi gefördert.