ActiCOAT

Sustainable anti-icing active systems by development of conductive coatings

The formation of ice, particularly on wind turbines and aircraft wings, causes considerable economic and safety issues. De-icing is usually carried out using external thermal, mechanical or chemical methods, in particular de-icing fluids. However, depending on the method, these processes require high quantities of consumables, energy, equipment or manpower. The project team is therefore developing structurally integrated anti-icing systems that can be heated electrically and prevent the formation of ice due to their surface properties. For this purpose, coatings are produced from a mixture of unsaturated polyester resin (UP) with carbon nanotubes (CNTs).

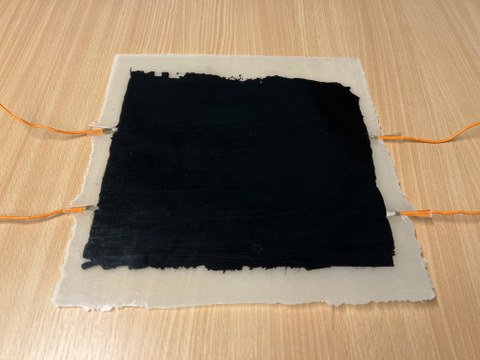

UP coating filled with CNTs contacted in preparation for the infusion process.

CNTs make it possible to increase the conductivity and thus enable heatability of the base material. The introduction of further additives serves to adjust additional icephobic properties. As part of the project work to date, corresponding material mixtures have been produced in a three-roll mill and further processed into films using labcoaters. After contacting with silver conductive paste, the films were embedded in fiber composite panels in a vacuum infusion process. Thermographic images of the plates were able to demonstrate heating when a voltage was applied. The integration of the anti-icing system for a demonstrator structure based on a NACA profile is to be implemented in the further course of the project.

Resulting contacted panel consisting of CNT-UP coating and glass fiber-epoxy composite.

01.04.2024 – 31.03.2026

Federal Ministry for Economic Affairs and Climate Action (BMWK): International networking initiative 'Collective Research Networking (CORNET)' within the funding measure 'Industrial Collective Research (IGF) international'

Funding code: 01IF00381C

DLR Projektträger

German Aerospace Center (DLR)

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Ron Luft (Thermoset Processes and Preforming)

Publications Ron Luft | TU Dresden

- Rafał Stanik (Thermoset Processes and Preforming)

Publications Rafał Stanik | TU Dresden