HYSTERESIS

Cyclic-Dynamic Properties of Bead Foams

Particle foams are characterized by a unique combination of low density, high mechanical energy absorption, extensive design flexibility, and low manufacturing costs, making them suitable for a wide range of applications. By selecting appropriate processing parameters, the cell structure properties – and thus the behavior of the molded parts – can be tailored to specific applications. However, according to the current state of research, significant uncertainties existed regarding the structure-property relationships of particle foams.

For instance, under global compressive loading, local phenomena such as bending, buckling, or tensile failure occur within the cell structure. Additionally, the mechanical behavior is significantly influenced by the enclosed cell gas and its compression. The interaction between cell gas and cell structure, as well as the phenomenology under cyclic loading, was a central focus of the research project.

Using a newly developed testing methodology for compression experiments under varying ambient pressures, the interactions between cell gas, cell structure, and base polymer were systematically investigated. Furthermore, the time-dependent mechanical properties of the particle foam were analyzed under cyclic compressive loading.

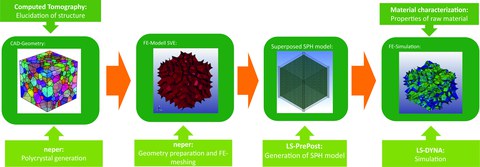

Ultimately, a modeling and simulation methodology was developed to describe the mechanical behavior of particle foams under compressive load, explicitly accounting for the influence of the enclosed cell gas.

Modeling and simulation strategy for expanded polypropylene foams with entrapped cell gas.

01.12.2020 – 31.03.2024

German Research Foundation (DFG)

Project number: 437872031

Funding Program: Individual Research Grants

© TUD/ILK

© TUD/ILK

Chair of Lightweight Systems Engineering and MultiMaterial Design

NameProf. Dr.-Ing. habil. Maik Gude

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 0, Room 71 Holbeinstr. 3

01307 Dresden

Deutschland

- Prof. Holger Ruckdäschel

Chair of Polymer Engineering, University of Bayreuth

- Dr.-Ing. Michael Müller-Pabel (Thermoset Processing and Preforming)

Publications Michael Müller-Pabel| TU Dresden

- Dr.-Ing. Bernd Grüber (Calculation Methods and Simulation)

Publications Bernd Grüber | TU Dresden