MOProAlgae: Rapid monitoring system Rapid monitoring system to optimize process control for the production of valuable active substances with microalgae

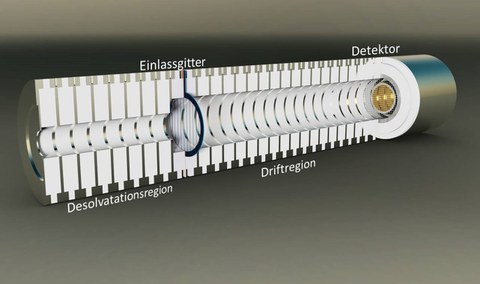

Within the MOProAlgae project, an innovative process for the real-time monitoring of production processes of natural, pharmaceutical-relevant algae additives is being developed. For the first time, ion mobility spectrometry (IMS) will be used in combination with electrospray ionization (ESI) to characterize biotechnological processes.

Algae active substances for the bioeconomy [...]

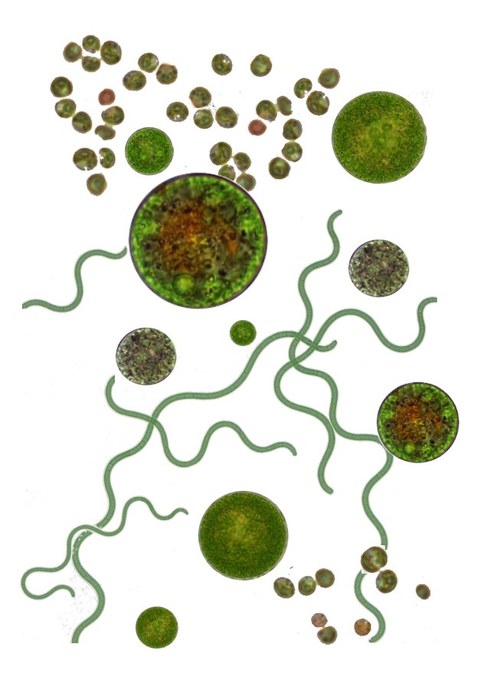

As a renewable source of raw materials, microalgae are very interesting for the bioeconomy. Because of their valuable cell components, algae offer a promising alternative to fossil raw materials and synthetically produced products. Microalgae are characterized by a very high growth rate and fast regeneration ability compared to agricultural plants. Microalgae can be cultivated in industrial scale seasonally independent and without the consumption of agricultural land.

Pilot plant (MINT GmbH) for microalgae cultivation at the Institute for Natural Materials Technology at TU Dresden.

Schematic illustration of various microalgae

In order to the efficiently production of specific algae ingredients, f. e. as dietary supplements and natural raw materials for the pharmaceutical and cosmetics industries, special methods for real-time process monitoring and quality assurance are required.

Currently, process monitoring in algae biotechnology can only be partially realized, systems for real-time determination and monitoring of formed substances are not commercially available. On the other hand, the production of algae biomass as a dietary supplement and for the use in the pharmaceutical and cosmetics industries must be GMP (Good Manufacturing Practice) certified.

The aim of this project is the development of an innovative process for the rapid monitoring of the manufacturing process of natural algae resources for the use in the cosmetics and pharmaceutical industries and as well the definition of certification criteria with regard to the processed products. The application of ion mobility spectrometry (IMS) in combination with electrospray ionisation (ESI) will be used for the first time to characterize biotechnological processes. The combination of both methods holds an enormous technical potential for fast at-line monitoring of bioprocesses.

Principle of an ion mobility spectrometer with preparation zone for liquid samples (desolvation).

The interdisciplinary consortium is headed by IFU GmbH Private Institute for Analytics includes the Institute for Natural Material Technology (INT) and the CIMTT Centre Of Production Engineering and Management at the TU Dresden and the Helmholtz Centre for Environmental Research GmbH (UFZ). The associated partners MINT GmbH and INALGO Dresden I GmbH support the consortium to transfer the process from the laboratory to the industrial scale.

Project funding:

The project is supported by the Sächsische Aufbaubank - funds of the European Union.

Project head:

IFU GmbH Privates Institut für Analytik (IFU)

Project thead TU Dresden:

© Ritz

© Ritz

Prof. Dr.-Ing. Thomas Walther

Send encrypted email via the SecureMail portal (for TUD external users only).

© Mann

© Mann

Scientist

NamePD Dr.-Ing. habil. Juliane Steingroewer

Head of Plant- and Algaebiotechnology

Send encrypted email via the SecureMail portal (for TUD external users only).

Project staff:

Institut für Naturstofftechnik | Bioverfahrenstechnik

© Mann

© Mann

Project researcher

NameDr.-Ing. Carolin Schott

Laser optical sensors, photobiotechnology

Send encrypted email via the SecureMail portal (for TUD external users only).

CIMTT - Zentrum für Produktionstechnik und Organisation

wissenschaftliche Mitarbeiterin

NameDipl.-Ing. Sylvia Franke-Jordan

Send encrypted email via the SecureMail portal (for TUD external users only).

CIMTT Zentrum für Produktionstechnik und Organisation

Visiting address:

Kutzbachbau, Raum E4 Helmholtzstraße 7a

01069 Dresden

Cooperation partners:

IFU GmbH Privates Institut für Analytik (IFU)

Helmholtz Zentrum für Umweltforschung - UFZ: Department Monitoring- und Erkundungstechnologien

Associated partners: :

- INALGO Dresden I GmbH

Project term:

01.06.2019 - 31.12.2021