Green Bioprinting - Novel Environment for Agglomeration of Plant Cells

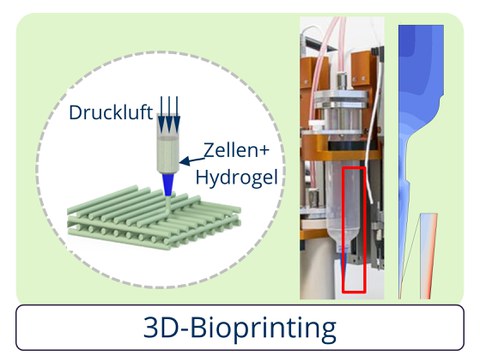

Biotechnological processes for the production of agents and additives by using plant cell cultures are getting more attention. The utilization of plant cell cultures as a production system offers a lot of advantages over traditional field cultivation. For increasing the energy and resource efficiency, processes adapted to plant cells are required. Integrated biotechnological systems using local and temporal heterogeneities to optimize the selectivity and velocity of conversion and material separation are highly promising. This is, where this research project comes in by creating an agglomeration matrix for plant cells based on the 3d-bioprinting. The so called bioprinting offers the possibility of creating even structured three dimensional immobilization matrices from previously cells in suspension using computer controlled systems. While bioprinting is already established in the field of Tissue Engineering, it has not been described in literature for plant cells yet. In cooperation with TU Dresden Centre for translational bone, joint and soft tissue research (TFO) bioprinting was successfully transferred to microalgae and is applied to plant cells in the recent project.

The aim of the project is to enhance the productivity of biotechnological processes with plant cells by embedding them in a hydrogel matrix reducing shear stress for the cells while cultivating, facilitating the purification of the target substance and encouraging a two-stage process. With regard to process optimization, it is important to consider the material exchange on phase boundaries between matrix and environment as well as inside cell agglomerates. The exchange is dependent on macrostructure and microstructure (e.g. porosity) of the hydrogel matrix. Therefore a detailed characterization and adaptation of the hydrogel matrix is necessary. By using methods of fluorescence microscopy, it is possible to make local and time-resolved statements about morphology of single cells and their agglomeration properties. A major aspect of developing a mathematical model to describe the underlying processes is the experimental parametrization. Parameters at micro and macro level should be considered in this work. Micro level means cell specific parameters like specific growth and production rate and morphological parameters of the embedded cells. At first, analysis of growth and product kinetics are carried out on a parallel cultivation system in shaking flasks with integrated exhaust gas analysis (RAMOS®). The macro level contains a parametrization of the three-dimensional matrix meaning the determination of pore size distribution and material-dependent diffusion coefficient. The mathematical description of this novel aggregation system forms the basis of computer-aided optimization. After all, the aim is an optimized matrix structure at macro and micro level which allows a homogenous material transport and corresponding ideal production conditions. The experimental validation of these matrix structures is implemented through 3D bioprinting.

Project funding:

DFG-Schwerpunkt „DiSPB“

Project head:

© Mann

© Mann

Scientist

NamePD Dr.-Ing. habil. Juliane Steingroewer

Head of Plant- and Algaebiotechnology

Send encrypted email via the SecureMail portal (for TUD external users only).

© SW

© SW

Postdoc

NameDr. rer. nat. Anja Lode

Group leader Bioprinting and head of cell culture

Send encrypted email via the SecureMail portal (for TUD external users only).

Project staff:

© Mann

© Mann

Project researcher on parental leave

NameDr.-Ing. Julia Emmermacher

Plant biotechnology, Development of modular bioreactors

Send encrypted email via the SecureMail portal (for TUD external users only).

Project term:

01.07.2016 - 30.06.2019