hyperBATH - Novel multi-point reaction system with integrated sensors and embedded cloud connection for aggregated data analysis

In the hyperBATH research project, 2mag AG in cooperation with essentim GmbH and the TU Dresden, Chair of Bioprocess Engineering, are developing a novel drybath system with mobile sensors (Sens-o-Spheres), modern database connection and LADS-based interface.

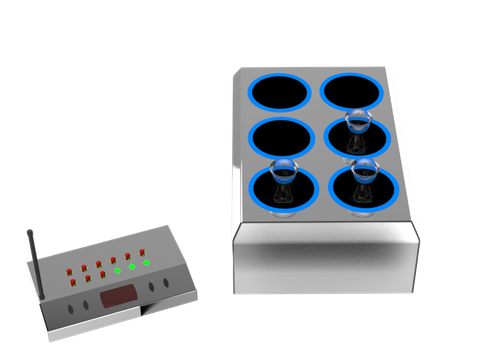

Conventional magnetic stirring systems currently rely almost exclusively on an externally mounted sensor for their measured value acquisition. The values supplied in this way - even in the physiological range between 20 and 40 °C - have been shown to deviate by up to 2 K from the directly measured value in the reaction volume. The measurement chain with a correspondingly necessary (temperature) control is therefore often sluggish, characterized by overshooting and undershooting, exhibits a static control deviation or is difficult to parameterize. The drybath to be developed by 2mag AG will offer the possibility of stirring at least 4 reactors with a volume of up to 500 mL with parameters specific to each location, controlling the temperature and documenting the pH value. The temperature should be controlled with a precision of 0.1 K, while maintaining a high dynamic range and at the same time avoiding overshoot above the setpoint. The setpoints for each incubation station should be individually adjustable with respect to both stirrer speed and temperature. The resulting differences in the setpoint temperatures between the individual incubation stations should be able to amount to up to 20 K. This poses a major challenge, particularly in terms of the thermal decoupling of the individual incubation stations.

The temperature and pH values are to be measured directly in the reaction volume without the use of interfering installations such as probes. This enables precise determination of the temperature without having to include thermal losses via the reactor wall. Another advantage is the independence from the reactor used. This allows the experimenter to freely decide which reaction vessel to use. The measurement is to be realized by sphere-like mobile sensors. The novel multisensors for temperature and pH are to be based on the Sens-o-Spheres previously developed by the TU Dresden. The battery-based measuring spheres have a size of about 9 mm in diameter and measure temperature. The measurement data is sent online to a receiver via a radio interface, which is a rigid coupling to a base station. The assignment of the sensors to the respective experiments running in the laboratory is ID-based.

Fig. 1: Design study for the novel hyperBATH system consisting of the drying bath with individually controllable incubation stations (right) and the gateway device for IoT integration with charging option for the sensor system (left).

For use in drybath systems, the functionality of the sensors is to be extended to include a pH value sensor, whereby the size of the sensor spheres is not to exceed 10 mm in diameter. Thus one of the smallest temperature compensated pH-value sensors worldwide shall be available. For use in biological environments, the sensors will be fully and bioinertly encapsulated. For reuse after the application in the reactor, the sensor spheres shall be able to be supplied with a charging voltage via induction.

Project funding:

Central Innovation Programme of the Federal Ministry of Economics and Climate Action (BMWi)

project number: KK5017812CR1

Project head:

© Mann

© Mann

Project researcher

NameDr.-Ing. Felix Lenk

Head of SmartLab-systems

Send encrypted email via the SecureMail portal (for TUD external users only).

Project staff:

© Mann

© Mann

Project researcher

NameDipl.-Ing. Tim Lauterbach

SmartLab-systems, sensor development

Send encrypted email via the SecureMail portal (for TUD external users only).

© blend3

© blend3

Project researcher

NameDipl.-Ing. Alexander Gießel

SmartLab-systems, sensor development

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner:

2mag AG

Kai Kress

https://www.2mag.de

essentim GmbH

Matthias Schuh

https://www.essentim.com

Project term:

01.10.2021 - 30.09.2023