smartFormulation - Development of an automated, function-integrated system for the production and quality evaluation of insoluble mixtures in pharmaceuticals, biotechnology and cosmetics, as well as the determination and recording of process-relevant par

Although the digitalization of processes and their machine-aided processing is becoming more and more important, especially with regard to increasing throughput, relieving the strain on employees, and improving the interpretability of results by means of complete documentation of process steps and parameters, a large number of experimental-analytical development processes are still largely characterized by manually performed and documented activities. Such a situation is found in analytical laboratories for the development of new emulsion formulations. Particularly in the manufacture of pharmaceutical mixtures, the exact concentration of pharmacologically active substances in the end product is of crucial importance. However, various conditions, such as the incomplete transfer of substance quantities when transferring substances into new containers, are still not taken into account in the manufacturing process. This inevitably leads to inaccuracies in the recipe of the formulation with regard to the resulting end product and makes upscaling to an industrial process considerably more difficult.

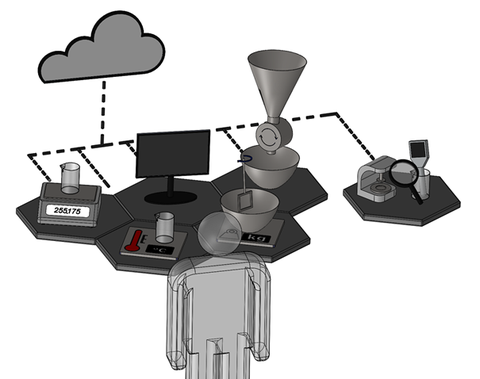

The aim of the project is the development and construction of a novel, semi-automated process line for the analytical development process of emulsion production with subsequent acquisition of quantitative and qualitative quality parameters. This includes the development of an automated, supported process route for the production of the actual emulsion as a mixture of different, mutually insoluble material phases, the analysis, digital recording and control of the critical parameters influencing the emulsion process, their documentation in a process document and the safeguarding of the process evaluation in a database. The process document also contains the quantitative and qualitative evaluation of the quality parameters of the resulting emulsion, which are determined mechanically after the production process. In order to maintain a high degree of flexibility and thus the possibility of adapting and substituting partial steps in the experimental laboratory environment despite the transition to a digitalized process, the process is developed as a partially automated, digitally controlled assistance system with modular process stations.

Project funding:

BMWK, ZIM AIF Kooperationsprojekt

Förderkennzeichen: KK5017827BR2

Project head:

© Mann

© Mann

Project researcher

NameDipl.-Ing. Christoph Otto

SmartLab-systems, lab automation

Send encrypted email via the SecureMail portal (for TUD external users only).

Project staff:

Cooperation partner:

SmartLab Solutions GmbH

https://www.smartlab-solutions.de/

Project term:

01.06.2023-31.05.2026