Development of technologies and processes for cultivation of dye producing fungi and for recovery of natural dye

In our everyday life dyes play an important role. They are used ostensibly for aesthetic reasons, such as the staining of textiles, leather or food, but also for functional reasons, such as the use as indicator or sensitizer. Dyes or pigments are used for staining. A dye is a coloring agent that is soluble in the application medium, whereas a pigment is not soluble. Until the 19th century dyes were only recovered from existing natural resources of different areas of nature, such as minerals, petals, resins, shells or snails. The dyes were blended by processors and their production required a lot of knowledge and experience. Beautiful and usable dyes were produced, which partly survived centuries and can still be admired in historic buildings, art works and textiles. However, the lengthily process of the production of natural dyes was expensive, so only the rich were able to afford the luxury of dyeing. Although in contrast to synthetic dyes natural dyes have significant environmental benefits, to this day the industrial production remains difficult due to the low yields and other factors, this covers inter alia: the limitation of the stocks of minerals, the large cultivation area and the seasonal fluctuations of plants, as well as ethical concerns regarding the use of dyes from animals.

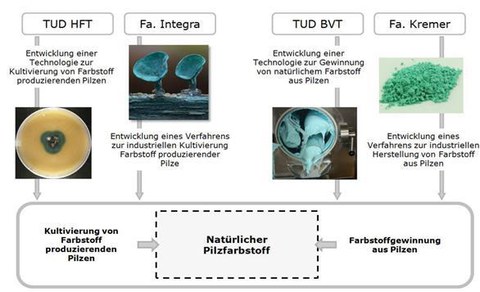

The group of fungi offers a great potential for the production of natural dyes and pigments. However, at present this potential is unused, although dye producing fungi are an interesting alternative to other natural sources and show a variety of different shades. In this project a process for the industrial cultivation of dye producing fungi will be developed, which provides large quantities of fungal material for dye recovery regardless of the environmental conditions. While in the hobby sector primarily fruiting bodies were collected and used for dyeing, in this project in addition the mycelium and possibly the substrate of the cultivation will be used for the extraction of the dyes. Hence the new technology of the cultivation of the dye producing fungi and the new process of dye recovery will enable an industrial production of dyes from fungi. The tackling of this tasks will be realized by the cooperation of the Professorship of Wood and Fibre Material Technology and the Chair of Bioprocess Engineering (TU Dresden), as well as the industrial partners Integra Hoyerswerda GmbH and Kremer Pigmente GmbH & Co. KG.

Project founding:

Central Innovation Programme of the Federal Ministry of Economics and Technology (BMWi)

project number of subproject “Development of technology for recovery of dyes from fungi”: KF2049821SU4

Subprojects:

- Development of technology for cultivating of dye producing fungi on laboratory scale (TU Dresden, Professur für Holztechnik und Faserwerkstofftechnik)

- Development of process for industrial cultivating of dye producing fungi (Fa. Integra Hoyerswerda GmbH)

- Development of technology for recovery of dyes from fungi (TU Dresden, Professur für Bioverfahrenstechnik)

- Development of technology for industrial production of dyes from fungi (Fa. Kremer Pigmente GmbH & Co. KG)

Project head (for subproject: Development of technology for recovery of dyes from fungi):

© Christian Hüller

© Christian Hüller

Senior Professor Bioengineering

NameProf. Dr. rer. nat. habil. Thomas Bley

Send encrypted email via the SecureMail portal (for TUD external users only).

Project researchers: (for subproject: Development of technology for recovery of dyes from fungi):

© Mann

© Mann

Project researcher

NameDr.-Ing. Susanne Steudler

Production of technical enzymes using solid state fermentation

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partners:

Integra Hoyerswerda GmbH

Dipl.-Wirtsch.-Ing. (FH) Robert Rys (GF)

Kühnichter Str. 30

02977 Hoyerswerda

Kremer Pigmente GmbH & Co. KG

Dr. Georg Kremer (GF)

Hauptstraße 41-47

88317 Aichstetten

Technische Universität Dresden

Faculty of Mechanical Science and Engineering

Institute of Wood and Paper Technology

Professorship of Wood and Fibre Material Technology

Univ.-Prof. Dr.-Ing. André Wagenführer

01062 Dresden

Technische Universität Dresden

Faculty of Mechanical Science and Engineering

Institute of Food Technology and Bioprocess Engineering

Chair of Bioprocess Engineering

Prof. Dr. rer. nat. habil. Thomas Bley

01062 Dresden

Project term:

01.03.2015 – 28.02.2018