inkoprod - Intelligent Production of Consum Goods.

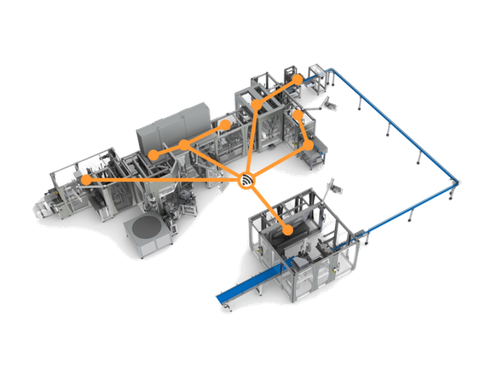

High-performance machines for mass production, and interlinked systems designed for flexibility are already being used today to manufacture plastic cups. These systems already reflect the trend towards intelligent production systems, but are unable to fully implement this trend due to the currently insufficiently developed system and process control technology. Due to the sensitive reaction to fluctuations in material and process parameters, paperboard processing is a suitable example of the need for the development of modern process control systems. A stable process control is therefore a prerequisite for the economical production of carton cups. Through modern process data management and intelligent evaluation methods, production systems can be enabled to make decisions independently and thus control process sequences intelligently. This technology must be used in the field of consumer goods production to provide cyber-physical production systems (CPPS) that enable both producers of consumer goods and production systems to work in a time- and resource-efficient manner and thus maintain and further increase the economic efficiency of production.

The aim of the research project is to enable processing modules to react independently and intelligently to changing production and environmental conditions so that product quality can be optimized. To this end, the means of process analysis, technology data management, simulation and machine intelligence are to be used.

Project funding:

The IGF project 18259 BR of the Forschungsvereinigung Industrievereinigung für Lebensmitteltechnologie und Verpackung e.V. was funded via the AiF as part of the program to promote joint industrial research (IGF) by the Federal Ministry for Economic Affairs and Energy on the basis of a resolution of the German Bundestag.

Project duration:

01.2016 - 07.2018

Project management and contact:

Project management:

Prof. Dr.-Ing. Jens-Peter Majschak

Project collaborator: Dipl.-Ing. Tobias Müller

Cooperation partner:

Institute for Machine Tools and Control Engineering at TU Dresden