Development and application of an adaptive 3D camera measurement technique for semi-analytical modelling of spray cleaning processes - MeMoSprüh

Measurement Methods and Modelling Spray Cleaning

The cleaning of machines and equipment with permanently installed Cleaning-in-Place (CIP) cleaning devices is an important process step in the food processing industry that ensures product quality and shelf life. In order to meet the growing economic and ecological demands, high process efficiency is required, which currently cannot be achieved due to a lack of design tools for process design and a lack of process knowledge. The project is intended to help make better use of potential savings in valuable resources such as water, chemicals and energy.

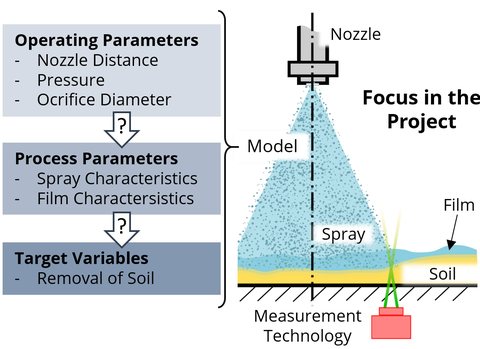

The aim of the project is the semi-analytical modelling of the spray cleaning process taking into account the dominant cleaning mechanism by identifying specific process variables relevant for spray cleaning. Experimental investigations provide a deeper insight into the interaction areas of the spray cleaning process. For this purpose, a new type of camera measurement technology with adaptive optics is being developed and used, which for the first time records the removal and movement of the thin layer of contamination in a high-resolution and three-dimensional manner. In addition, high-resolution data regarding the spray and the film flow resulting from the droplet impact on the surface are determined. On this basis, important process knowledge can be gained about the physical relationships between spray, film flow and contamination removal. This enables the development of semi-analytical process models with which a cleaning prediction can be made and which can be used for process optimisation. The process models and application recommendations that will be freely available after the end of the project will make it possible to design cleaning processes in practice in a system-specific manner with the least possible experimental and computational effort. A great economic benefit arises in particular for SMEs in the manufacturing industry and in the area of development and calculation services. SMEs from the field of flow measurement technology benefit from new metrological approaches with which layer and film flows that were previously difficult to access can be measured with high resolution.

Project funding:

This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V. (AiF) and the Federal Ministry for Economic Affairs and Climate Action (01lF22492).

Project duration:

07/2022-12/2024

Project management and contact:

Project leader: Prof. Dr.-Ing. Jens-Peter Majschak

Project manager: Dipl.-Ing. Manuel Helbig

© Nils Eisfeld

© Nils Eisfeld

Cleaning Technologies

NameDipl.-Ing. Manuel Helbig

Wissenschaftlicher Mitarbeiter

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner:

Technische Universität Dresden, Institute of Circuits and Systems, Chair of Measurement and Sensor System Technique