Chocolate-specific simulation model for flushing processes in closed systems – SchokoSIM

© TU Dresden

The German chocolate industry can look back on a successful tradition. The decisive factor for this success is above all the high quality of the manufactured products. In order to continue serving recent market trends, it is necessary to produce different chocolate products on the same plant. This increases the risk of quality-reducing cross-contaminations such as the carry-over of flavours, colours and other ingredients, making thorough cleaning imperative. Flushing processes for removing the previous chocolate mass are therefore increasingly becoming the focus of targeted process improvements, but have not yet been fully understood. Due to the high complexity of the machines and plants and the poor possibilities for monitoring and evaluating the flushing process, improvement processes can only be carried out with high experimental effort.

Summary

The aim of the project was to develop a tool for designing and analyzing industrial flushing processes in the chocolate industry. Computational fluid dynamics was identified as a suitable tool, as it provides a detailed insight into the mechanisms involved in flushing processes.

A simulation model was created that is able to take into account the variation in chocolate-specific properties resulting from the wide range of products offered by chocolate manufacturers. Experiments were carried out to investigate how the diverse product properties, which are input variables for the simulation, can be determined and modeled. The construction of a test bench made it possible to investigate the flushing process experimentally. This enabled the validation of the simulation model and the identification of challenges in planning, implementation and monitoring of industrial flushing processes.

Material Properties

The project was divided into several phases. In the first project phase, the focus was on the experimental investigation and modeling of the material properties of fully melted chocolate. The measurement of a large number of chocolate samples showed that all samples exhibit strong non-Newtonian flow behavior. Furthermore, the investigations demonstrated that the chocolate does not flow below a certain shear stress, the so-called yield stress. These properties were taken into account accordingly in the modeling. The parameters of the identified rheological model were determined by further experiments using industrially widely available technology (e.g. rheometers). In addition to the rheological properties, the density of the chocolates was determined. In contrast to the flow properties, it did not show any significant temperature dependence. The thermal properties were determined using various laboratory methods (e.g. DSC) and modeled accordingly.

Flushing Test Bench and Simulation Model

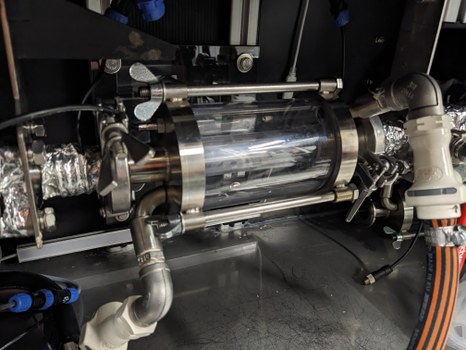

The second project phase consisted of the conception, design, construction and commissioning of the flushing test bench. This was carried out by the first research facility. Various detection options for the flushing front and the flushing progress were tested. Measuring segments were developed as part of the project. They are transparent, can be cooled and heated due to a double-walled design and may be removed from the test bench. Other detection options, such as a capacitive measuring system, were also tested as part of the project. Simultaneously, the simulation model was developed by the second research facility. It was created within the OpenFOAM software, because it is open source and can be used without a license fee. The material models identified in the first project phase were implemented within OpenFOAM and a section of the test rig was modeled to enable the validation of the simulation results in the subsequent third project phase.

Flushing Investigations

The third phase of the project consisted of carrying out experimental and numerical flushing investigations and drawing conclusions from the generated results for industrial flushing processes. In the experiments, the flushing process was stopped after a defined flushing time. The chocolate contained in the measuring segments was then cooled and subsequently removed and measured by cutting it into small cross sections. The results of the flushing simulation were determined in the same way so that a direct comparison of the results was possible. The simulation model matched the experimental data very well, signifying a successful validation.

Results

Various findings were obtained from the flushing investigations. First and foremost, the entire process was divided into two successive phases. During the first phase, called core removal phase, the mass inside the pipe is pushed out. A high yield stress of the flushing chocolate is useful for this. This ensures that there is a larger area inside the pipe in which the locally occurring shear stress does not exceed the yield stress. This in turn, results in the formation of a larger solid plug that pushes out the previous chocolate. However, a higher yield stress also leads to a significantly higher demand on the pump performance. In the second phase, called layer removal phase, the layer of previous chocolate that has remained on the pipe wall is removed. A low viscosity of the previous chocolate is helpful here, as this leads to a higher velocity in the residual layer and therefore faster removal given a set mass flow of flushing chocolate.

Based on these observations, the project was able to derive recommendations for industrial flushing processes. An increase in temperature results in a reduction of viscosity. While this has a positive effect on the layer removal phase, the core removal phase is negatively affected. Simultaneously the required pump performance is reduced, while the energy required for heating increases. If both the flushing and previous chocolate are heated, the results from the experiment and simulation show almost no differences in the flushing progress. It follows that a similarly good flushing result can be achieved at low temperatures using less energy. When the production line is emptied before flushing, part of the previous chocolate can be recovered and reused. However, prior emptying does not improve the flushing result. A lower mass flow has a small influence on the core removal phase, as the shear stress in the center of the pipe reduces. For a small mass flow this results in a larger plug flow area and thus a larger cleaned area compared to using the same amount of flushing chocolate at a large mass flow. At the same time, the flushing time increases with a low mass flow.

The greatest influence on the flushing process are the rheological properties of the two involved chocolates and their combination. According to the observations mentioned above, the chocolates for any flushing process can be chosen based on the material properties, which may be determined using the methods proposed in this project. Alternatively, the required flushing time for any combination of chocolates can be calculated using the flushing simulation.

The goals of flushing processes depend strongly on the company and production. Goals may be high-energy efficiency, low consumption of flushing chocolate, large amounts of recovered previous chocolate or short flushing times. Different strategies in designing the flushing process were presented as part of the project with respect to the goals. The simulation model is available for flushing simulations of any combination of chocolate masses. Furthermore, a simplified model was developed in the project, which provides results for isothermal processes within a few minutes.

Conclusion

Before this project, the design of flushing processes in the chocolate industry was typically based on empirical data to which large safety factors had to be added. With the completion of the project, three new design tools are available: a test bench for flushing experiments at laboratory scale, a numerical model for CFD-based flushing simulations and a simplified model. These tools will enable a more detailed investigation and design of chocolate-specific flushing processes in the future.

Project funding:

This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V. (AiF) and the Federal Ministry of Economic Affairs and Energy (IGF 20672 BR).

Project duration: 01/05/2019 – 30/06/2023

Project management and contact:

Project leader: Prof. Dr.-Ing. Jens-Peter Majschak

Project manager: Dipl.-Ing. Matti Heide

© Nils Eisfeld

© Nils Eisfeld

Cleaning Technologies

NameDipl.-Ing. Matti Heide

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner: Technische Universität Dresden, Institute of Fluid Mechanics, Chair of Fluid Mechanics