Rigid Packages with a Biobased Barrier Coating

Development of compresion drawn packaging parts made of fibre based materials with a functional bio-based barrier layer and the correspinding inline application technology

When packaging food and cosmetic products, it is particularly important that they are optimally protected. Natural fiber-based cartonboard packaging offers good stability but only a limited barrier effect against external influences such as moisture or oxygen. Therefore, additional functional barrier layers are often used.

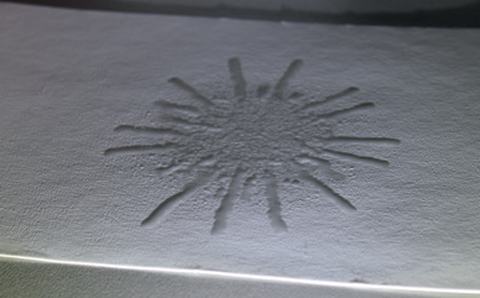

Sternförmiges Sprühbild von Wasser auf Karton.

In this project, we are pursuing an innovative approach in which the barrier layers are applied to the rigid package after the molding process. First, the barrier layer is present as a liquid and then cures on the formed part. Similar processes are known form beverage can production and are now being adapted for natural fiber-based packaging.

We, the Chair of Processing Machinery/Processing Technology, are significantly involved in this project. We not only manufacture the packaging moldings, but also develop the application and dosing process for the barrier liquid together with Krautzberger GmbH. Through our expertise in processing technology, we are helping to ensure that the barrier layers can be effectively applied to the molded packaging part. Our partners from the Chair of Wood and Plant Chemistry are working closely with KLG Liquida to develop the composition and manufacturing process for a novel bio-based barrier layer.

Project duration:

02.2023 - 03.2025

Project management and contact:

Project leader: Prof. Jens-Peter Majschak

Project manager: Dipl.-Ing. Lena Berthold

© Nils Eisfeld

© Nils Eisfeld

Processing Systems

NameDipl.-Ing. Lena Berthold

Forming of Fibre Based Materials

Send encrypted email via the SecureMail portal (for TUD external users only).