Infrastruktur und Service

Lösungsmittelnassspinnanlage © ITM/TUD

Bikomponenten-Schmelzspinnanlage © ITM/TUD

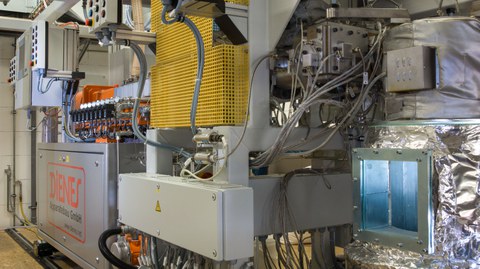

Stabilisierungsanlage © Lichtwerke Design Fotografie

Carbonisierungsanlage © Lichtwerke Design Fotografie

MAGEBA Steckschützenwebmaschine SL RTEC 1200/1 © ITM/TUD

Greiferwebmaschine DORNIER - Drahtwebanlage © ITM/TUD

Greiferwebmaschine DORNIER P1 (mit OpenReedWeaving-Technologie) © ITM/TUD

Multiaxial-Nähwirkmaschine Malitronic® © Mirko Krziwon

Hochleistungs-Nähwirkmaschine Malimo 14024 mit multiaxialen Schusslegesystemen © ITM/TUD

Hochleistungs-Nähwirkmaschine Malimo 14022 mit Parallelschusseintragssystem © ITM/TUD

RR-Raschelmaschine MiniTronic 808 © ITM/TUD

Flachstrickmaschine Steiger Aries 3D © ITM/TUD

Flachstrickmaschine Steiger Aries 3D Technology © ITM/TUD

Flachstrickmaschine Steiger Aries 3 © ITM/TUD

Flachstrickmaschine Stoll ADF 530-32 BW knit & wear © ITM/TUD

Stickmaschine SGY 0200-650D © ITM/TUD

ZSK Racer 1W Stickmaschine © ITM/TUD

Multifunktionelle Beschichtungsanlage © BGR/Fotothek

Das ITM verfügt über eine sehr gut ausgebaute Infrastruktur mit modernster Maschinentechnik und Geräten. Neben hochleistungsfähigen Textilmaschinen, z. B. Multiaxial-Nähwirk-, Jacquardweb-, Mehrlagenstrick-, TFP- und Flechttechnik, bieten beispielsweise die Einrichtung eines Technikums Faser-Kunststoff-Verbunde sowie die Installation einer Vakuuminjektionsanlage für FVW-Platten, einer Thermopresse für FVK-Anwendungen, einer Biaxial-Zugprüfmaschine und Hochgeschwindigkeitsprüfmaschine für Rovings, textile Halbzeuge und Verbundbauteile neue Chancen und Möglichkeiten, die Forschungsarbeiten im Bereich der Verarbeitung von Hochleistungsfaserstoffen für die Entwicklung von Technischen Textilien für vielfältige Anwendungen auf hohem Niveau durchzuführen. Darüber hinaus lassen sich mit einer multifunktionalen Beschichtungsanlage mit integrierter Plasmaanlage maßgeschneiderte Grenzschichten und neue Produkte am ITM erzielen. Mit einer Labornassspinnanlage und Bikomponentenschmelzspinnanlage werden neuartige maßgeschneiderte hochfunktionelle Faserstoffe, beispielsweise für Bio-, Medizin- und Hochleistungstextilien entwickelt und hergestellt. Für die Erforschung und Entwicklung von Kohlenstofffasern steht dem ITM in Zusammenarbeit mit dem Institut für Leichtbau und Kunststofftechnik der TU Dresden eine vollständige Stabilisierungs- und Carbonisierungsanlage zur Verfügung. Modernste Trenn- und Fügetechnik für Bekleidung und Technische Textilien sowie CNC- und Roboter-Nähtechnik für Verstärkungstextilien an der Professur für Entwicklung und Montage von textilen Produkten am ITM runden die umfassende Infrastruktur ab. Diese Techniken bieten hervorragende Möglichkeiten einer textilgerechten Montage textiler Preforms.

Eine Auflistung der am ITM installierten Maschinentechniken finden Sie auf folgenden Seiten:

- Versuchsfelder Textilmaschinen

- Konfektionslabore

- CAE-Labore

- Analyse-, Mess- und Prüflabore

Somit verfügt das ITM mit den beiden Professuren "Textiltechnik" und "Entwicklung und Montage von textilen Produkten" über alle Maschinentechniken entlang der textilen Prozesskette von der Filamenterspinnung über die verschiedensten Garnbildungstechniken, neuartige 2D und 3D textile Konstruktionen, Ausrüstungstechniken bis hin Konfektionierungstechniken für verschiedenste Hightech-Anwendungen, wie z. B. Composites, Textilbeton, Biomedizintextilien, textile Architektur und Funktionstextilien.