Infrastructure and Service

Solvent wet spinning machine © ITM/TUD

Bicomponent melt spinning machine © ITM/TUD

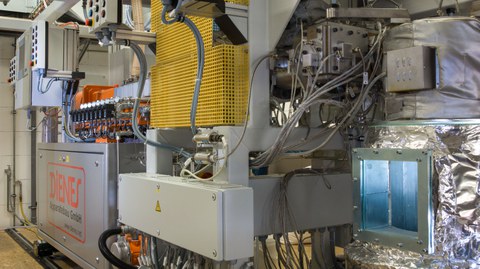

Stabilisierungsanlage © Lichtwerke Design Fotografie

Carbonisierungsanlage © Lichtwerke Design Fotografie

MAGEBA shuttle weaving machine SL RTEC 1200/1 © ITM/TUD

Rapier weaving machine DORNIER - wire weaving machine © ITM/TUD

Rapier weaving machine DORNIER P1 (with OpenReedWeaving-Technology) © ITM/TUD

Multiaxial stitch bonding machine Malitronic® © Mirko Krziwon

High-performance stitch bonding machine Malimo 14024 with multiaxial weft insertion systems © ITM/TUD

High-performance stitch bonding machine Malimo 14022 with parallel weft insertion system © ITM/TUD

Double-needle-bar raschel machine MiniTronic 808 © ITM/TUD

Flat knitting machine Steiger Aries 3D © ITM/TUD

Flat knitting machine Steiger Aries 3D Tecchnology © ITM/TUD

Flat knitting machine Steiger Aries 3D © ITM/TUD

Flat Knitting Machine Stoll ADF 530-32 BW knit & wear © ITM/TUD

Embroidery Machine SGY 0200-650D © ITM/TUD

Embroidery Machine ZSK Racer 1W © ITM/TUD

Multifunctional coating plant © BGR/Fotothek

The ITM is equipped with a state-of-the-art infrastructure including modern machinery and technical devices. The ITM has at its disposal a variety of high-performance textile machines in the fields of, e.g., multiaxial, stitch-bonding, jacquard weaving, multi-layer knitting, tailored fiber placement and braiding technology. New possibilities for conducting excellent research in regards to the processing of high-performance fiber materials for the development of technical textiles are opened up through the establishment of the Technical Center Fiber-Reinforced Plactic Composites as well as the installation of a vacuum injection moulding machine for fiber composite panels, a thermal press for fiber-reinforced plastics, a biaxial tensile testing maschine and a high-speed test machine for rovings, textile semi-finished products and composite parts. Moreover, customised interfaces as well as innovative products can be designed at the ITM by means of a multifunctional coating machine with integrated plasma plant. Also, new types of customized high-performance fiber materials, e.g. for bio, medical and high-performance textiles, are developed and manufactured using a laboratory wet spinning machine and a bicomponent melt spinning machine. In terms of research and development of carbon fibers, the ITM - in collaboration with the Institute of Lightweight Engineering and Polymer Technology of the TU Dresden - is provided with a complete stabilisation and carbonisation plant. State-of-the-art separation and joining technologies for clothing and technical textiles as well as CNC and robot sewing technologies available at the Chair of Development and Assembly of Textile Products complement the infrastructure profile of the ITM. These technologies offer excellent possibilities regarding the textile-compatible assembly of textile preforms

In the following, you can find a list of various machines available at the ITM:

- Test field textile machinery

- Assembly laboratories

- CAE laboratories

- Analysis, measuring and testing laboratories

Thus, the Chairs of "Textile Technology" and "Development and Assembly of Textile Products" are equipped with all machinery along the textile process chain, from the spinning of filaments to various yarn formation techniques, innovative 2D and 3D textile structures, equipment technology up to various assembly technologies for numerous high-tech application, e.g. composites, textile-reinforced concrete, biomedical textiles, textile architecture and functional textiles.