Influence of heat conduction in the process zone on the process-structure-property linkages of a modified LPBF process in aluminum alloy processing

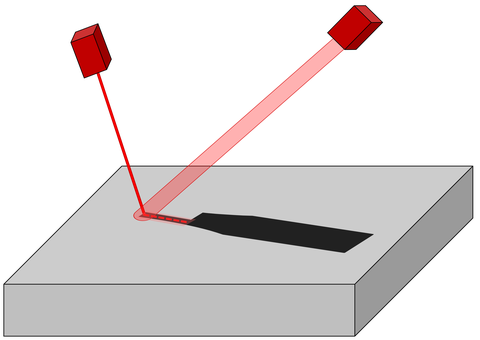

Laser powder bed fusion process with two lasers

The Laser Powder Bed Fusion (LPBF) of metallic powders for the production of highly stressed, individualized components is already in industrial use, e.g. in automotive, aircraft and mechanical engineering. For these applications, there is a need for application-oriented research work on the economic use of LPBF and thus the attainment of competitiveness.

Extensive research results are available for the classic LPBF with 1 laser. As a result, however, these still mean a high production effort compared to classical production processes and thus lead to a low dissemination compared to the potential.

The objective of the planned process modification is to significantly reduce the production time for LPBF using the material AlSi10Mg as an example by increasing the build rate while maintaining the previously achievable quality. Fot this purpose, a second laser intervening around the working point, which is coupled to the main laser by means of control technology is employed. The coupled-in energy can be varied. This allows heat pre-treatment and post-treatment of the process zone to be implemented directly to improve component quality. Within the scope of the project, the pre-treatment of the powder for the removal of hydrogen is addressed in particular. Essential to this is an improved understanding of the process through systematic quantification of the process-structure-property linkages of the manufactured components and a description in a mathematically based knowledge model.

SMEs can use this to realize an entry into or an extension of the application possibilities of LPBF. Contract manufacturers in particular can reduce manufacturing effort and thus manufacturing costs by reducing upstream and downstream manufacturing steps, thus significantly increasing competitiveness and application breadth.

Cooperations

Ansprechpartner

© TUD/NEFM

© TUD/NEFM

Dipl.-Ing. Alexander Raßloff

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 350 George-Bähr-Straße 3c

01069 Dresden

© TUD/NEFM

© TUD/NEFM

Dipl.-Ing. Ulrike Gebhardt

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 355 George-Bähr-Straße 3c

01069 Dresden

Dipl.-Ing. Lennart Linden

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 350 George-Bähr-Straße 3c

01069 Dresden

© TUD/NEFM

© TUD/NEFM

Professor for Computational and Experimental Solid Mechanics

NameProf. Dr.-Ing. habil. Markus Kästner

Send encrypted email via the SecureMail portal (for TUD external users only).

Chair of Computational and Experimental Solid Mechanics

Visiting address:

Zeunerbau, Room 353 George-Bähr-Straße 3c

01069 Dresden