Flow Optimiser

Flow Optimiser: A Shell-and-tube heat exchanger modification that increases Energy Efficiency in the Oil, Gas, Power & Chemical Process Sectors

EUROPEAN COMMISSION- Executive Agency for Small and Medium-sized Enterprises

| Responsible: | M.Sc. Richard Schab |

| Duration: | 11/2018 to 01/2021 |

| Funding Institution: |

European Union - Horizon 2020 |

Project partners:

Project goals

- Development of devices for generation of uniform flow in shell-and-tube heat exchangers

- Heat exchanger fouling mitigation by flow uniformity

- Development of heat exchanger CFD models in real scale

- Derivation of a fouling cost calculator for estimation of costs related to HX fouling and flow maldistribution

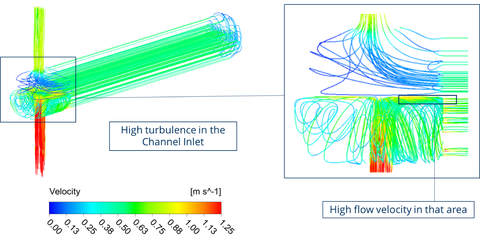

Figure 1: CFD Simulation of a 2-Pass shell-and-tube heat exchanger

Project background

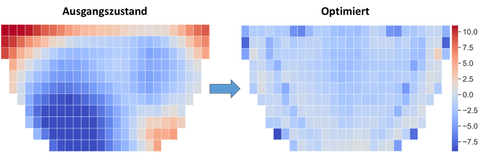

Within the framework of the EU project FlowEnhancer, the non-uniform flow through shell-and-tube heat exchangers and its effect on the formation of deposits (fouling) is being investigated. Fouling leads to higher pressure losses in heat exchanger tubes and generally to decreased heat exchanger efficiency. This means that a higher energy supply must be realised, for example, to bring crude oil up to the temperature required for fractional distillation. The associated CO2 emissions and costs need to be reduced. The current project, developed a device that leads to a uniform flow through the entire tube bundle pass.

Figure 2: Relativ (%) deviation from theoretical average velocity in each tube of the first pass of a 2-pass shell-and-tube heat exchanger