Photogrammetry in froth flotation

Contact person: Dipl.-Ing. Tine Marquardt Dr.-Ing. Tobias Lappan Dr.-Ing. Sascha Heitkam

Funding: FlexiQuick project (Innovative measurement techniques for multiphase processes in resource technology 11/2022 -12/2025)

Cooperation: Helmholtz-Institute Freiberg for Resource Technology

Motivation

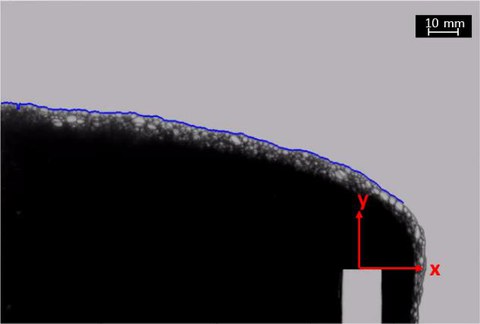

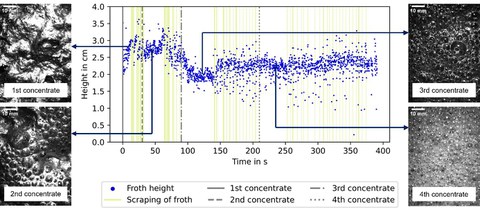

In flotation processes, the recovery of valuable particles is affected by the height of the overflowing froth (Fig. 1), which varies depending on operating conditions (Fig. 2). An online measurement of the height of the overflowing froth would allow better process control and thus a more efficient flotation process. In this project, commercially available sensors are tested and new optical measurement techniques for determining the froth height are developed. A particular challenge is the required high temporal and spatial resolution. Experiments will be carried out on overflowing foam flows on a laboratory scale as well as flotation experiments on both laboratory and industrial scale.

Objectives

-

development of an optical measurement system to determine the foamability at different flotation conditions under variation of physicochemical and hydrodynamic parameters (cooperation with the FlotSim project https://www.flsmidth.com/en-gb/flotsim)

-

evaluation of commercially available measurement techniques (LIDAR, 2d/3d laser scanner) for their applicability to foam flows

-

development of a method for the determination of froth height by photogrammetry

Methods

-

commercially available measuring equipment for characterization of froth properties (optical measurement of the size distribution and particle loading of bubbles, conductivity-based measurement of the liquid fraction in the froth)

-

LIDAR sensors for pointwise measurement of the froth height

-

laser scanners for 2D/3D height profile measurements

-

time-resolved photogrammetric reconstruction of the foam/froth height profile (usage of multiple time-synchronized cameras and image processing methods)

Publications

Lappan, T.; Herting, D.; Ziauddin, M.; Stenzel, J.; Shevchenko, N.; Eckert, S.; Eckert, K.; Heitkam, S. X-ray Particle Tracking Velocimetry in an Overflowing Foam. Appl. Sci. 2023, 13, 1765. https://doi.org/10.3390/app13031765

Fig. 1: Determination of the height profile (blue line) of an overflowing foam – optical measurement through transparent side wall.

Fig. 2: Change in froth appearance and height during a batch-flotation process.