Measurement of flotation recovery by means of 4D particle tracking velocimetry

Motivation

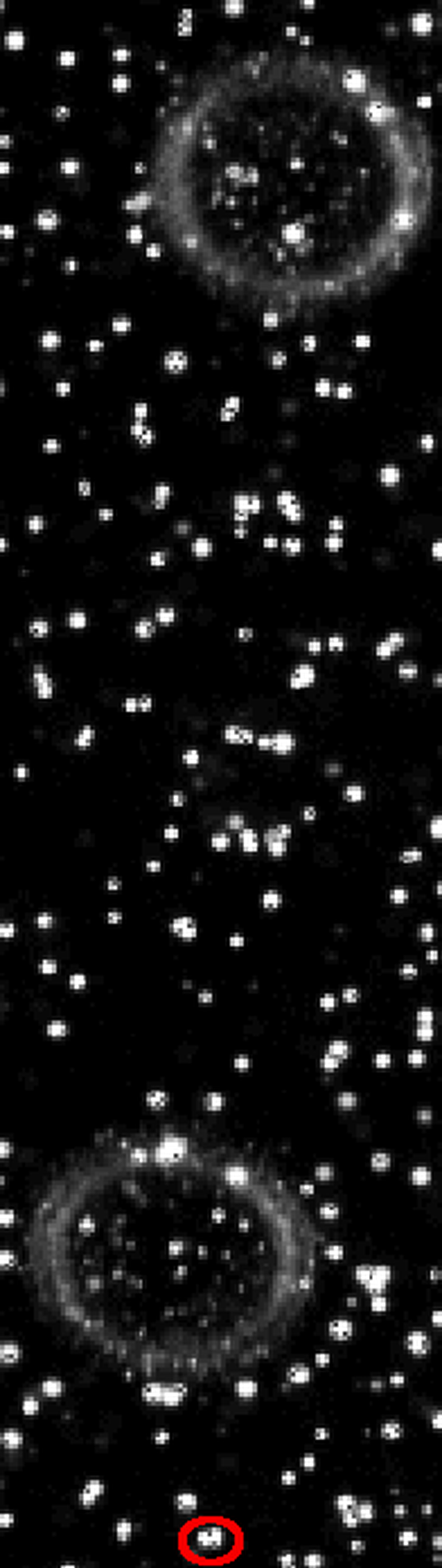

Fig. 1: Attachment of a particle to a rising bubble.

Froth flotation is a fundamental technique to separate and concentrate aqueous suspensions of minerals, precipitates or inorganic waste constituents. Billions of tons of ores are treated annually by flotation in the mining industry to separate the valuable minerals e.g. copper sulfide, galena or tungsten from the gauge within the ores. The separation process is based on the different wetting behaviors of minerals. Hydrophobized target particles attach to the fluidic interface of gas bubbles rising in a suspension (Fig. 1) whereas the invaluable minerals are hydrophilic and sediment to the bottom of the flotation cell. On the top of the flotation cell, a froth with the hydrophobic particles is formed, which is skimmed off to gain the purified particles.

The efficiency of the froth flotation process depends on the encounter of particle and bubbles based on the hydrodynamics within the cell and the surface chemistry of the pulp for the film rupture during the attachment process. Through this wide range of length scales from the micro-scale on the liquid film between bubble and particle towards the macro-scale of hydrodynamics within an industrial flotation cell, flotation is a complex process and not fully understood until now. Although many researchers developed analytical models for particular microprocesses, they are leaking on validation data.

Thus, we focussed on the novel method to measure the recovery rate, which is the number of target particles at various times in a reference volume. The method is based on optical 4D particle tracking velocimetry (PTV) which is used to compare bubble and particle trajectory and identify attached particles on a bubble.

Experimental setup

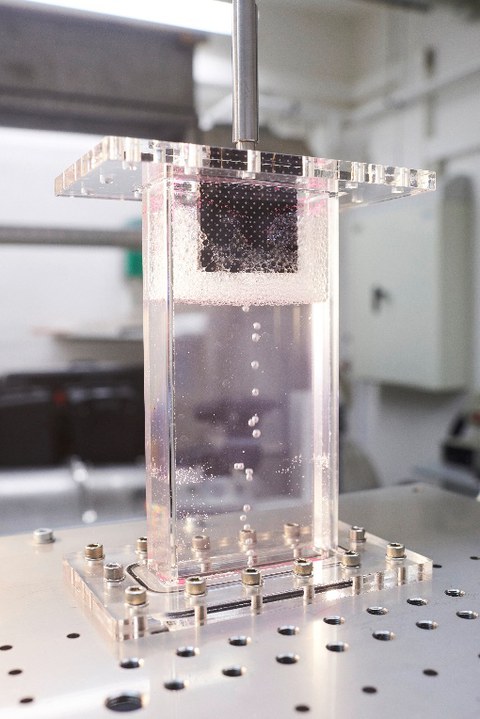

Fig. 2: Experimental setup of the bubble column with calibration plate.

The 4D PTV measures simultaneously particle and bubble trajectory in 3D with a high temporal resolution. We applied this measurement technique to a bubble column as illustrated in Fig. 2. The multiphase flow consisted of air bubble chain (diameter = 2mm), fluorescent model particles made out of polymers (diameter = 30 – 100 µm) and a mixture of surfactants and deionized water to enhance the attachment process between bubble and particles.

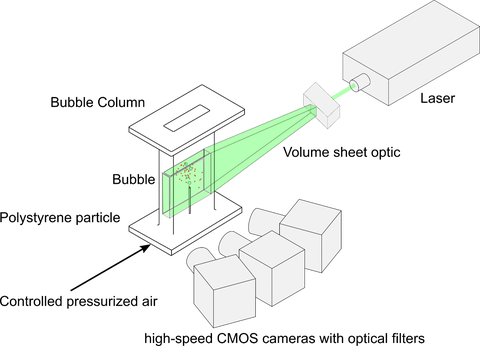

Fig. 3: Experimental setup of the 4D particle tracking system.

For the measurement, the particles and bubbles were illuminated by a laser and the scattered light was captured by three high-speed cameras (Fig. 3). To avoid an overexposure of the bubbles and an accompanied covering of particles in the nearfield of the bubble, we used an optical filter. The filter would pass emitted fluorescent light of the particles, but block the intense scattered light from the bubble. Fortunately, the bubbles also reflected the fluorescent light with a lower intensity which enabled a simultaneous recording of bubbles and particles.

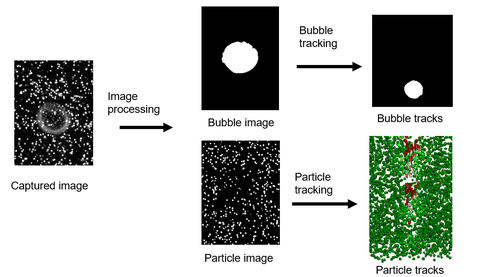

Fig. 4: Calculation of bubble and particle trajectory.

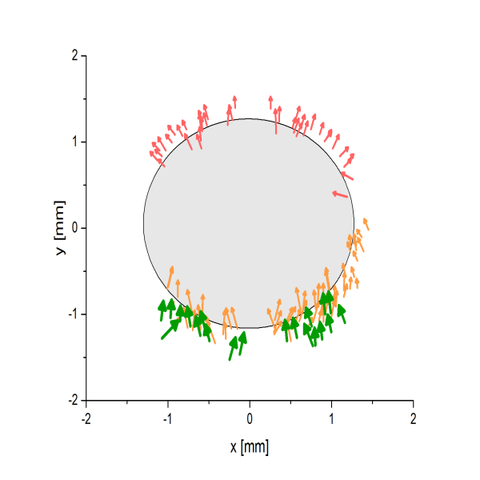

Fig. 5: Example of classified particles from measured data. Green: Attached particles. Yellow: Attachment candidates. Red: Non-attached particles.

After the image recording, the images were divided into particle and bubble images to triangulate both objects separately via various image processing steps (Fig. 4). For the triangulation, an advanced particle tracking algorithm as the Shake-the-Box algorithm (Schanz et.al, 2016) was used. This algorithm computed the Lagrangian tracks of particles through triangulation with an extensive use of their temporal information. In the last step, both sets of trajectories (bubble and particle) were combined again to calculate the recovery rate as a ratio of attached particles to all particles. The attached particles were located in their relative position to the bubble surface and relative velocity to the bubble.

Results & Outlook

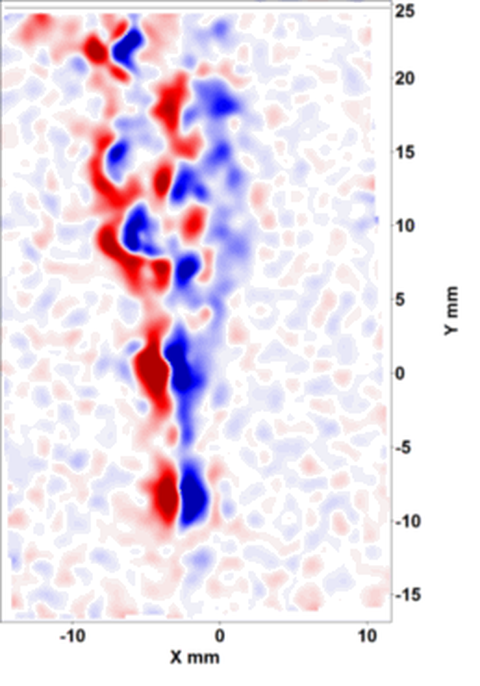

Fig. 6: Diagram of vorticity in z-direction within bubble column.

Preliminary investigations focused on attachment regions of the model particles on the bubble (Fig. 5) and the visualization of the flow field within the bubble column to explain the attachment regions (Fig. 6). The majority of particles were attached to the trailing edge of the bubble that could be caused by the bubble vortices within the bubble wake.

In further investigations, we will vary the physicochemical and geometrical parameters such as contact angle or bubble-to-particle radius, and the Reynolds number of bubbles to measure the recovery rate. This data will be used to evaluate and enhance existing analytical models.

References

D. Schanz, S. Gesemann, A. Schröder: Exp. in Fluids Vol. 57 (2016)

Publications

A. E. Sommer,..., M. Nikpay, S. Heitkam, K. Eckert: A novel method for the measurement of flotation recovery by means of 4D particle tracking velocimetry, Flotation’17, Cape Town (South Africa), 13.-16.11.2017, submitted to Minerals Engineering (2017)