Enhanced microalgae separation using metastable froth in flotation

Contact person: Behnam Keshavarzi

Funding: Deutsche Forschungsgemeinschaft (DFG), grant number of KE 2827/1-1.

Cooperation with Chair of Bioprocess, TU Dresden and the team of Mechanics of Interfaces and Multiphase Systems (MIM), Institut Charles Sadron.

Motivation:

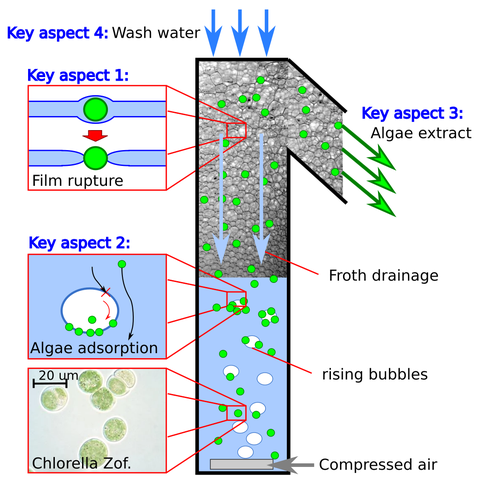

Key aspects of Algae flotation research

Flotation has shown to be promising method for algae separation from cultivation media because its low costs and easy extension to large scales. In algae flotation, for a high recovery and grade, not only the chemical composition of the pulp solution should be accurately formulized to enhance algae-bubble attachment, but also the froth should be designed to ensure adequate liquid drainage. A sufficient drainage requires large bubble diameters and a long residence time. The long residence time can be achieved either by low gas flow rates or by a tall froth zone. Both cases require a high froth stability, and hence a high concentration of additives. This not only increases the cost but also leaves a significant chemical footprint in the cultivation media and the concentrated solution. Moreover, high froth stability is disadvantageous for further processing, as the extracted froth needs a long time to collapse. We previously have shown that foams with medium stability lead to the most efficient flotation process for protein separation FLOTAG. In a metastable foam, small bubbles exist at the bottom and large bubbles at the top of the foam zone. The small bubbles offer the advantage of large interfacial area and convey a high amount of target material from the pulp to the foam, where rapid coalescence of bubbles enhances the foam bubble size. The resulting liquid drainage yields a dry froth and a high grade at the top. In addition, the extracted foam collapses rapidly at the outlet so that the concentrate can be conveniently processed.

Goals:

- Efficient adsorption of hydrophobized algae to the rising bubbles. This will be achieved by tuning the hydrophobization of the algal cells via the selected collectors as well as by optimizing the dynamic flotation parameters (Key aspect 1, Figure above).

- Optimum froth stability by controlled coalescence. To obtain a high grade of the extract, a strong drainage of the froth has to be realized. This will be achieved by a controlled coalescence in the froth, accelerating the drainage (Key aspect 2, Figure above).

- Modeling of algae flotation process to balance the requirements on the froth stability with regard to the objectives of high grade (lower froth stability) and high recovery rate (higher froth stability). This involves the complex interaction of the coalescence speed and the drainage rate.

Methods:

- Dynamic surface tension tests (PAT, Sinterface): to measure the dynamics of hydrophobized algae adsorption on air interface.

- Zeta potential measurements (Zetasizer NanoBrook90): to track the surface charge of the algae in presence of collectors.

- Microfluidic thin film pressure balance setup: to study the film stability in presence of algae where dynamics of the film thinning and statistics of the film rupture are investigated.

- Dynamic foam analysis (DFA-100, Krüss): to study the behavior of algae froth in respect of coarsening and drainage rate.

- Flotation experiments: to evaluate the separation efficiency of proteins in ABS separation.