Experimental and computational analysis of rate dependence during cutting of viscoelastic natural materials

Cutting is characterized by a complex interplay of deformation, fracture and friction processes that, in case of viscoelastic materials, significantly depend on cutting speed. An increase of cutting velocity or cutting at reduced temperature may consequently lead to a transition from ductile to brittle fracture behavior which deteriorates the product quality. The aim of the project is to analyze the complex rate-dependent cutting process with respect to deformation and fracture on model basis and to describe the transition from ductile to brittle both in the experiment and in a numerical model.

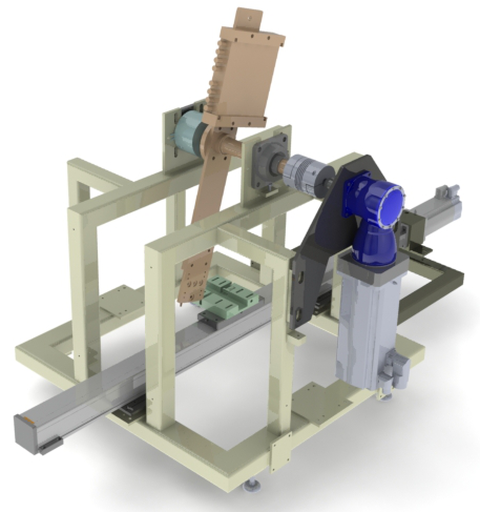

The experimental investigations will be carried out with a viscoelastic model systems, and their deformation and fracture behavior will be analyzed at various temperatures and velocities; experimentally inaccessible strain rates will be covered by applying temperature-time superposition (TTS). The data build the basis for the numerical modeling of the rate- and temperature dependent deformation behavior at finite deformations using viscoelastic material models. These models will be used to simulate cutting processes, and cutting tests over a large velocity range will be performed using a special device. This results in routines for a combined direct-indirect analysis of the material behavior by means of experiment and TTS, which may further be used for analyzing thermomechanical effects during cutting.

In cooperation with:

- Professur für Numerische und Experimentelle Festkörpermechanik (Professor Markus Kästner)

Supported by:

- Deutsche Forschungsgemeinschaft

Project researchers and contact:

© Sven Ellger

© Sven Ellger

Research Assistant

NameDipl.-Ing. Dennis Schab

Food Process Engineering

Send encrypted email via the SecureMail portal (for TUD external users only).