Identification of physical-chemical properties of soils for structure-based cleaning optimisation in the food industry 2 - StReo 2

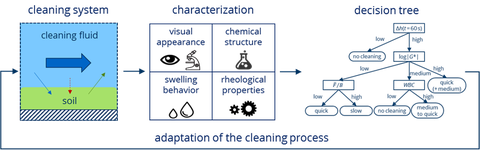

A growing variety of products and therefore smaller batch sizes require frequent product changes in food production. This poses new challenges with regard to the design of the cleaning processes required in between. The interactions between the complex composition of the soil and the cleaning fluid are usually not sufficiently known. Therefore, cleaning processes are not adapted to the cleaning requirements of the respective products. This often results in oversizing with a high consumption of water, chemicals and energy, creating a discrepancy between environmental and consumer protection. However, a profound comprehension of the cleaning-relevant properties of individual food soiling would enable the adaptation of the cleaning process as required and thus conserve valuable resources.

As a continuation of the previous research project IGF 19640, the aim of this research project was to identify the influences of chemical and physical properties of individual soil components on the cleaning behavior of complex soils and thus to expand the knowledge base of soil properties relevant for cleaning. Complex soils were composed of selected thickening agents and a whey protein isolate in different ratios. The analyses provided a structured insight into interactions between various ingredients and swelling or cleaning fluids of different temperatures and sodium hydroxide concentrations. The methods previously developed in the project IGF 19640 and in other projects of both research institutes to characterize soil properties relevant for cleaning have been optimized and further methods were established.

A basic understanding of the chemical structure of the soils was gained by analyzing the composition, in particular the content of carbohydrates, proteins, fats and ash as well as the molecular masses using gel permeation chromatography (GPC). The development of the Soil Composition Change experiment (SoCoC) enables the analysis of structural changes in the soil caused by the interaction with a swelling fluid. Scanning electron microscopy also provided an insight into soil-specific differences in surface roughness and cracking.

A method for determining the water binding capacity and water solubility index of soil powders was already established in IGF 19640. The soil powders were dispersed into the swelling fluid for a defined swelling period and swelling and solubility were determined on a mass-specific basis after centrifugation. A new method has been established to continuously gauge swelling and solubility. Soil powders were overlayed with the swelling fluid and analyzed via optical transmission measurements. The swelling behavior of soil layers was also optically recorded using a swelling basin and a camera setup. The increase in layer thickness in the respective swelling fluid was continuously determined. Due to the different measuring principles used, the results of the different methods complement each other, leading to a comprehensive insight into the swelling and solubility behaviors of soils.

The method outlined in IGF 19640 for determining the rheological properties of soil layers in contact with the respective swelling fluid has been significantly optimized. The use of replaceable soil carriers for the rheological measurements considerably reduced the period required for the experiments and also allowed the use of industrially relevant surfaces as soil carrier. Stiffnesses and loss factors determined by oscillatory rheometry offer insight into the mechanical properties of soil layers with respect to swelling fluid and changes over swelling time. In addition, the pull-off tests carried out on soil layers provided further insights into the mechanical soil properties during macroscopic displacement. For this purpose, soil layers were swollen in varying swelling fluids for a defined period and then removed from the substrate using a scraper blade. The average pull-off resistance was determined from the measured forces. Furthermore, the respective forces provided information on the site-specific swelling condition.

The two research institutes now have numerous methods available to describe solubility and swelling properties relevant to cleaning, as well as the mechanical properties of swelling soil layers.

The cleaning behavior of the respective soils in a plane channel flow with equally varied cleaning fluids showed similarities to the results of the methods used to describe the mechanical, solubility and swelling behavior of the soils. Using multivariate statistical methods for exploratory data analysis, relationships could be illustrated and also linked to the observed cleaning mechanisms. The developed decision tree facilitated the extraction of easily interpretable and comprehensible rules from the collected data set, and for the first time, provided an ordered property relevance. This allows the targeted selection of methods to characterize soil properties interacting with varying cleaning fluids. Ultimately, a suitable cleaning fluid can be chosen iteratively in food industry.

Small and medium-sized enterprises (SMEs) in the food processing industry often have to carry out product changes on their systems, and hygienic cleaning processes occur more frequently than in large companies. Therefore, SME’s, in particular, can benefit from the knowledge gained in order to save energy, water and chemicals during cleaning. The mechanical and plant engineering industry in Germany, which is predominantly composed of SMEs, can also utilize the established methods to predict the cleaning behavior of products. Thereby, upon delivery of a machine or a system, more resource-efficient cleaning recommendations can be expected. Considerable benefit was also achieved for future scientific analyses of soil properties. The project results will substantially contribute to future knowledge expansion, not just in the food industry, but also in the cosmetics and pharmaceutical sectors.

Project funding:

This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V. (AiF) and the Federal Ministry of Economic Affairs and Energy (IGF 20861 BR).

Project duration: 04.2020 – 07.2022

Project management and contact:

Project leader: Prof. Majschak

Project manager: Sebastian Kricke

© Clemens Troll

© Clemens Troll

Cleaning Technologies

NameDipl.-Ing. Sebastian Kricke

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner:

Technische Universität Dresden, Institute of Natural Materials Technology, Chair of Food Technology