Soil Improvement

Whenever the building ground cannot withstand the structural loads, either the foundation system has to change or the construction ground must be improved. The methods of subsoil improvement include e.g. compaction and replacement. Vibro compaction is used in coarse-grained soils such as sands and gravel. The depth vibrator causes vibrations in the ground so that the surrounding soil grains lose contact with each other and rearrange in a denser grain package and with fewer voids.

If the subsoil consists mainly of fine grains, an improvement by means of compaction is no longer possible. Therefore, for replacement the depth vibrator is also provided with a lock on the underside through which sand or gravel can be induced into the ground and additionally compacted when pulling the vibrator. This creates sand or gravel columns in the ground which increase the stiffness and bearing capacity of the ground.

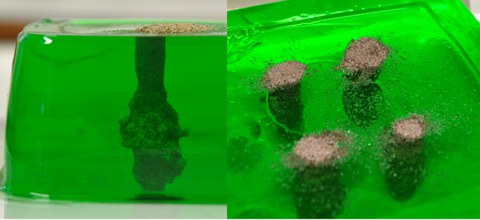

Compacted sand columns in fine-grained, soft soil (here jelly)

Für dieses Box steht leider noch kein Text zur Verfügung.

Für dieses Box steht leider noch kein Text zur Verfügung.

Seals in hydraulic earth dams, likedikes, are often incomplete, imperfect or even completely missing. In case a leakage occurs, under certain circumstances the stability of the earth damcan be endangered. Within the framework of a research and development project, TPH Bausysteme GmbH, GGL Leipzig GmbH and the Institute of Hydraulic Engineering and Technical Hydromechanics (IWD) of TU Dresden have developed a low-pressure injection (LPI) method for soils. With the help of the process and the use of acrylate gels, in the hydraulic earth daman increased sealing level is achieved compared to the initial state. The sealing method must be mobile, quick to use and lightweight, so that an immediate in-situ measure is feasible even in case of average.

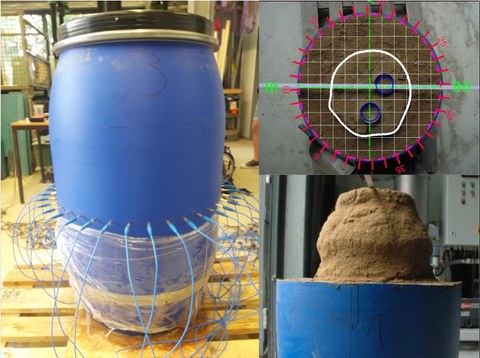

Mid-scale tests in barrels for testing the detection sensitivity of the used geophysical method

On the basis of large-scale tests, using large-scale dams (dam height approx. 2m, inclination approx. 1:2) in the hydraulic engineering testing hall of the IWD and small and medium-scale tests in the soil mechanical laboratory of the Institute of Geotechnical Engineering, the experimental testing, scientific analysis and technological optimization of the injection procedure are carried out. In addition, research work is currently being carried out on an optimized detection method with the aid of geophysics, which is to be used for the non-destructive proof of the injection result (quality control).

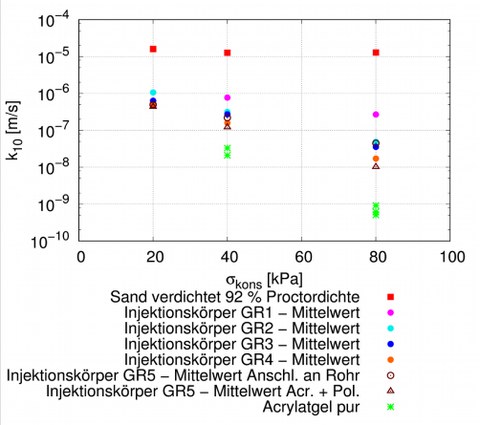

Permeability tests of samples from grouted bodies in comparison to sand and pure acrylate gel (median from more test result)

In geotechnics there are a many reasons for measures regarding soil or rock improvement. One possible way of soil improvement is compaction. For this purpose, cement-bound construction materials are generally used which have the advantage of high strength and low deformability. However, their setting time is relatively high. An alternative to cement-bound injection materials are reactive polymers, with whom similar strengths can be achieved. Unlike cement-bound construction materials, their setting time is lower and the materials react more deformable to external loading. Thus, compacted columns by reactive polymers in the ground could become an alternative to cement-bound construction materials, especially in cases where rapid strength development is essential.

Currently, reactive polymers are used especially in tunnel construction for crack and gap grouting. Their suitability for subsoil improvement is currently being investigated at the Institute of Geotechnical Engineering.

Soil improvement with reactive polymers in the laboratory at the Institute of Geotechnical Engineering