Reference textile for the C³ project

Table of contents

Project data

| Titel | Title Referenztextil für das C3-Projekt | Reference textile for the C3 project Förderer | Funding Institut für Massivbau, TU Dresden Zeitraum | Period 02.2017 – 01.2018 Leiter | Project manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Bearbeiter | Contributors Dr.-Ing. Harald Michler Dipl.-Ing. (FH) Frank Neumann Dipl.-Ing. Jan Panzer Projektpartner | Project partner Institut für Textilmaschinen und Textile Hochleistungswerkstofftechnik, TU Dresden | V.Fraas Solutions in Textile, Helmbrechts | TUDATEX GmbH, Dresden | Teijin Carbon Europe GmbH, Wuppertal | CHT Germany GmbH, Tübingen |

Report in the annual report 2018

REFERENCE TEXTILE FOR THE C3 PROJECT

Based on the developments in the C3-B1 project and further efforts of the companies involved in the project, a reference material for carbon textile reinforcements, based on the structure of the TUDALIT reinforcement according to abZ Z-31.10-182, was produced at the end of 2017. In 2018, there were extensive tests for this initial production and also the various projects of the C³ were supplied.

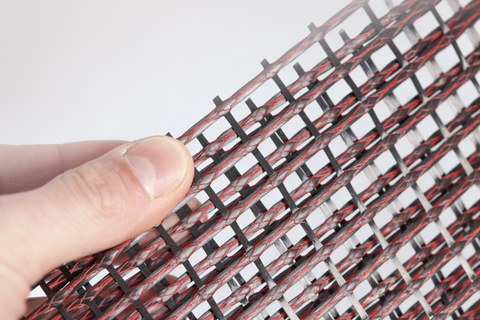

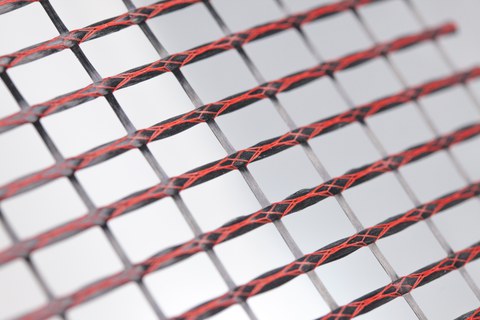

Reference grid made by V.Fraas

With this textile, carbon-heavy tows manufactured by Teijin Carbon, impregnated with a polymer-based coating from CHT and produced on the machines of V.Fraas, a lot of information was gathered in 2018, to enable different fields of application, suitable for outdoor environmental conditions. The aim is to almost double the design strength compared to that of the TUDALIT approval. And as a result, to achieve a more economical work in the strengthening and reinforcement of new components. The necessary tests are carried out, not only at the Institute of Concrete Structures but also at the facilities of the involved partners in the C³-project, to assess, for example, the fire behaviour of the material. Through the E-project quality management, all production values and test values are collected and evaluated carefully.

Referenzmaterial Fertigung V.Fraas

Currently, the material can be produced as flat sheet material at V.Fraas, TUDATEX have already succeeded in manufacturing a rolled textile, without loss of strength and bonding behaviour. In order to work with larger aggregates in the associated concrete matrix, a second textile structure, manufactured from the same materials, is studied as a biaxial structure, with heavy tows of equal yarn count in warp and weft direction and about 25 mm yarn distance. Analogous to the linguistic usage in reinforced concrete construction, a Q-mat (biaxial) and an R-mat (uniaxial, acc. to abZ TUDALIT) are available.

Alternatively, a second material based on a Lefatex impregnation within the TUDALIT approval is currently in development. The main experiments are prepared and will be carried out in 2019