Eco-concretes with carbon-fiber reinforcements

Table of contents

Projektdaten

| Titel | Title TP Congreen.Carbon.Research – Planung, Durchführung und Auswertung von relevanten Versuchen zur Erlangung eines Zulassungsszenarios im Verbundvorhaben Congreen.Carbon.System (CCS): Ökobeton als Massenbaustoff für wirtschaftliche und leichtere Betonsysteme | Subproject Congreen.Carbon.Research – Planning, implementation and evaluation of relevant tests to obtain an approval scenario in the joint project Congreen.Carbon.System (CCS): Eco-concrete as a mass building material for economical and lighter concrete systems Förderer | Funding Bundesministerium für Wirtschaft und Klimaschutz (BMWK) Zeitraum | Period 09/2023 – 08/2026 Teilprojektleiter | Subproject leader Prof. Dr.-Ing. Steffen Marx Bearbeiter | Contributor Dipl.-Ing. Paul Heber Projektpartner | Project partners Implenia Construction GmbH, München | CARBOCON GmbH, Dresden | Kleihues Betonbauteile GmbH & Co. KG, Emsbüren |

Report from year book 2023

Carbon reinforcement meets eco-concrete

Eco-concrete b.congreen by Implenia Construction GmbH

Reinforcements made of carbon fiber-reinforced plastics (CFRP) allow a considerable reduction of the dimensions of the concrete cover of concrete components due to their resistance to corrosion. Due to the correlating saving of the amount of the highly CO2-emitting concrete binder cement, this is an increasingly established approach in construction practice for realizing more CO2-efficient components. The use of eco-concretes can further enhance this saving effect. Thanks to their cement-reduced composition, eco-friendly concretes have a more positive CO2 balance than traditional concretes. If CFRP reinforcement is used, the decreased pH value of eco-concretes has no negative effect. Thus, CFRP-reinforced eco-concrete components represent a novel two-pronged approach to reducing CO2 emissions in concrete construction.

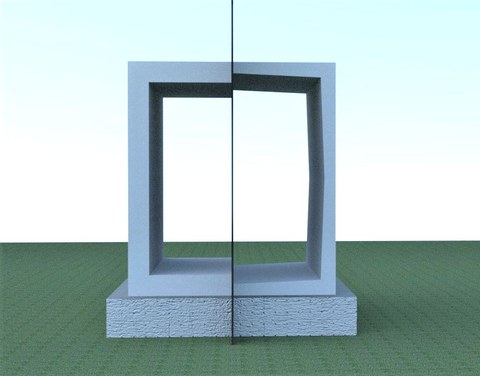

Based on this premise, the goal of the research project “Congreen.Carbon.System (CCS): Eco-concrete as a mass building material for economical and lighter concrete systems” is to develop prefabricated frame components for railroad construction. In addition to saving primary resources and minimizing CO2 emissions, the research project aims to produce durable components which can be manufactured quickly and cost-effectively at once, thus reducing the economic impact of construction.

Due to the innovative combination of materials, their interactions are initially studied in small-scale tests on the composite. These tests involve scrutinizing the strength development of the eco-concrete utilized and its bond properties with CFRP reinforcement. The concrete matrix will be optimized to improve these properties in the further stages of the project. The results are supplemented and expanded by a complex test program on large components, which is used to investigate the global load-bearing behavior of the developed CFRP eco-concrete components. The thereby obtained data is utilized in the development of verification and design approaches that facilitate designing, dimensioning and constructing the prefabricated components.

The overall construction will finally be tested on a large demonstrator. The tests can form the basis for a general building authority approval for the new prefabricated parts.

Short description

Further development of conventional precast reinforced concrete elements into more material-efficient and climate-friendly precast carbon concrete elements

Aims of the project are the development, practical application and setting the course for achieving market maturity of precast concrete elements made of standardized eco-concrete in combination with reinforcements made of carbon fiber reinforced thermoplastics (CFRP). This new combination is to be theoretically investigated for infrastructure structures, specific: in small railroad bridges, technically developed, and realized with a demonstrator.

Railroad bridge construction is considered one of the supreme disciplines in civil engineering due to the high loads caused by train traffic and the dimensional accuracy required at the same time. Successful implementation in this segment and its process optimization would make a significant contribution to reducing the CO2 footprint of construction.

Objectives of the project are:

- Significant reduction of CO2 emissions,

- Saving of primary resources,

- Reduction of economic impacts,

- Increased service life of structures,

- Cost reduction through faster and resource-saving construction.

In the research project, we want to create the preconditions for the widespread use of eco-concretes as the most important mass construction material for reducing CO2 emissions. The feasibility of using eco-concrete in railroad bridge construction shall be demonstrated in a pilot application. In the subproject of TU Dresden, we will carry out experimental investigations on small and large components as well as the demonstrator, and develop and investigate a monitoring concept.