Chemical prestressing of carbon-reinforced concrete

Table of contents

Project data

|

Titel | Title |

Summary of funding period 2

This project aims to enhance the structural performance of folded and shell-shaped carbon-reinforced concrete structures using the chemical prestressing technology. During the first period of TRR 280, significant advancements were achieved in developing the chemical prestressing technology. However, it was observed that long periods of underwater curing are required to achieve the full expansion of the concrete. This is considered unpractical in a construction site or even in a prefabrication factory. Therefore, the second phase of this project will focus on developing rapid curing techniques to expedite the expansion process of concrete and study their influence on the structural behavior of chemically prestressed carbon-reinforced concrete structures.

Report from the annual report 2023

Self-stressing carbon-reinforced concrete

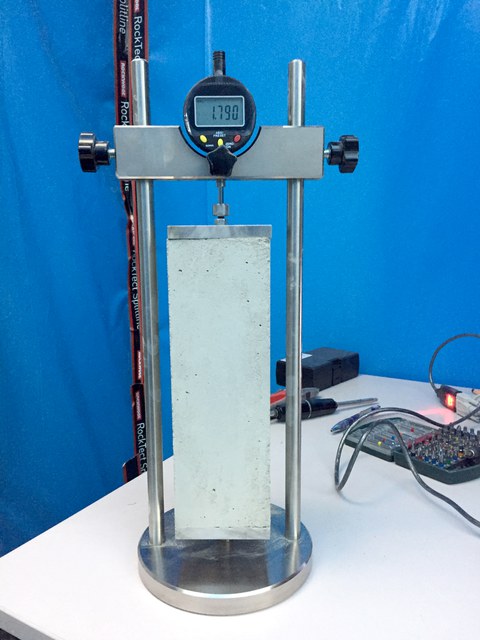

Experimental setup to measure the expansion of carbon-reinforced concrete samples

Implementing prestress in concrete structures entails inducing compressive stresses into the concrete elements prior to their utilization. This method greatly increases the rigidity of concrete components and beneficially impacts their stress distribution. Incorporating prestress aids in enhancing resistance against cracks and minimizing structural deformations. Although prestressing is well-established for steel-reinforced concrete, it becomes notably challenging for structures utilizing textile reinforcement e.g. made of carbon fibers. This difficulty primarily stems from the susceptibility of fiber materials to lateral pressure. Moreover, the practicality of utilizing multiple hydraulic jacks for prestressing a considerable amount of carbon fiber rovings is limited.

Chemical prestressing stands out as a highly favorable option to mechanical prestressing. Thus, this project seeks to utilize the chemical prestressing technology specifically tailored for carbon-reinforced concrete. The method revolves around integrating swelling admixtures into the concrete mixture. When the concrete expands, it generates tensile stresses on the carbon fiber reinforcement, resulting in the application of compressive stresses within the concrete. This process enables prestressing without requiring mechanical apparatus or supplementary steps.

During the first phase of the project, an expansive concrete that can yield high expansion rates while maintaining good mechanical properties was developed. This concrete was then used to produce self-stressing carbon-reinforced concrete. For this aim, concrete plates of dimensions 500 mm × 150 mm × 30 mm were produced using the already developed expansive concrete. Each plate was reinforced with high strength carbon textile reinforcement. To monitor the expansion of concrete, and thus the development of the prestressing force over time, distributed fiber optic sensors technology was used. The preliminary results of the experiments have shown that the developed expansive concrete is capable of stretching the textile reinforcement, which in return apply a compressive stress on the concrete causing the prestressing action. The amount of compressive stress developed depends mainly on the amount of expansive agent added and the amount of textile reinforcement used.

Report from the annual report 2022

Expansion tests on concrete samples

Expansion test on concrete samples

Prestressing of concrete structures is the process of introducing compressive stresses into the concrete members before using them. With the help of prestressing, concrete elements can be considerably stiffened and their stress state can be favorably influenced. Structures can thus achieve better crack resistance and less deformation. Prestressing is well established for steel reinforced concrete, but for structures with carbon and especially textile reinforcement, the prestressing process is extremely complex, mainly because of the transverse pressure sensitivity of the fiber materials. Furthermore, it is not feasible to provide a large number of hydraulic jacks to prestress the large number of carbon fiber rovings.

One of the most promising alternatives for hydraulic prestressing is chemical prestressing. Hence, the aim of this project is to use the chemical prestressing technology to prestress carbon-reinforced concrete. The technology is based on the addition of swelling admixtures in the concrete. When the volume of the concrete increases, it exerts tensile stresses on the carbon fiber reinforcement, which in return, apply compressive stresses in the concrete. Thus, prestressing takes place without mechanical devices or additional operations.

One of the most important phases in this project is to develop a suitable concrete mixture that gives reasonable amount of expansion with maintaining good concrete characteristics. Therefore, a number of concrete mixtures were manufactured. All mixtures had the same components except for the swelling agent, which substituted between 10 and 20 % of the cement by weight. The results have shown that expansive agent additions of more than 17 % lead to very high expansion; however, the compressive strength is decreased significantly. On the other hand, expansive agent additions of below 11 % leads to small expansion. The most appropriate additions were found to be between 12–15 %, which produced good expansion, while maintaining a reasonable compressive strength. This percentage will be used in the next phase of the project, which includes reinforcing the concrete with textile carbon reinforcement to study the prestressing force.

Report from the annual report 2021

Chemical prestressing of CRC

Measurement setup for tests with restrained expansion

With the help of pre-stressing, concrete components can be considerably stiffened and their stress state can be favourably influenced. Structures can thus achieve better crack resistance and deform very little despite minimised weight. Prestressing is well established for steel reinforced concrete, but for structures with carbon and especially textile reinforcement, the prestressing process is extremely complex, mainly because of the transverse pressure sensitivity of the fibre materials.

In our own preliminary work, the technology of chemical prestressing (or self prestressing) of concrete elements was therefore further developed and perceived as an efficient method for introducing prestress into carbon-reinforced concrete (CRC). The technology is based on the application of swelling admixtures in the concrete, which, in interaction with the strain restraint, induce tensile forces in the reinforcement and consequently compressive forces in the concrete. The prestressing thus succeeds without mechanical devices or additional operations.

The aim of the subproject is to develop methods for the chemical prestressing of shell-shaped and folded CRC structures. Compared to the prestressing of plane components, additional stiffening effects are activated in spatially prestressed elements, which lead to the expectation of very favourable component behaviour. First, suitable material combinations are designed and their potential for chemical prestressing is investigated in detail. Subsequently, folded or curved chemically prestressed element cells are analysed. Individual test specimens are examined in a long-term test with regard to the tension force losses due to creep and relaxation.

The main gain in knowledge of the project consists in answering the question of whether the chemical swelling process of the concrete matrix can lead to a dimensionally stable and time-stable prestressing of spatially curved or folded thin-walled carbon-reinforced concrete elements and whether this prestressing can lead to a significant increase in the efficiency of the components.