TRC under compression – influence of biaxial load application

Table of contents

Project data

|

Titel | Title |

Report from the annual report 2023

Stress from all sides

Resin bath for embedding the overlapping carbon reinforcement

During the first stage of the project, carbon-reinforced concrete cubes were analysed under uniaxial compressive loading. Multiple parameters that significantly reduced the load-bearing capacity were identified, such as the impregnation material. These impacts were equally evident in different concretes. In phase 2 of the project, we aimed to investigate additional transverse compressive and tensile stresses induced to the specimens. Whilst concrete is assumed to have increased strength under multi-axial compressive stresses, the cracking resulting from tensile stresses leads to reduced strength.

To assess the applicability of these principles to carbon-reinforced concrete, we fabricated

200 × 200 × 40 mm³ measuring discs using Pagel TF10 fine-grained concrete and carbon-fiber reinforcement grids. We varied the production method (casting and lamination), the number of reinforcement layers, the grid’s orientation, and various grid types with different impregnations, yarn thicknesses, and mesh widths.

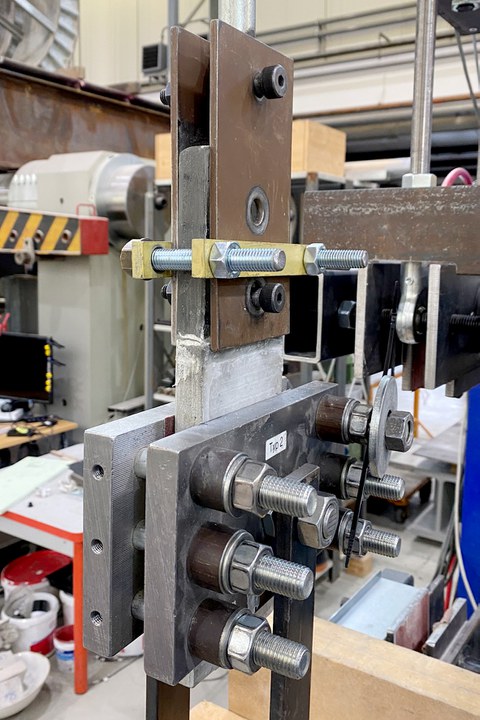

The biaxial loads were applied in the plane of reinforcement in all tests. To ensure uniform load application without lateral restraint, we used the well established loading brushes for the application of compressive loads. For the introduction of tensile forces, a new anchoring construction for the carbon grids was required due to the limited space available in the triaxial testing machine. Ultimately, we embed the carbon grids in resin blocks and placed them in a clamping construction.

Biaxial compressive tests showed that the presence of the grid reinforcement had the greatest effect on the specimen’s load-bearing capacity. Splitting in the reinforcement plane was the dominant kind of failure. The other variable parameters were of secondary importance. The tests with a combined compressive-tensile loading, however, substantiated the assumption that there is a reduction in the applicable compressive strength to cracked specimens. The crack pattern was the decisive factor, affected substantially not only by the applied tensile force but also by the reinforcement parameters such as the reinforcement ratio and impregnation.

Report from the annual report 2022

Tension in compression design

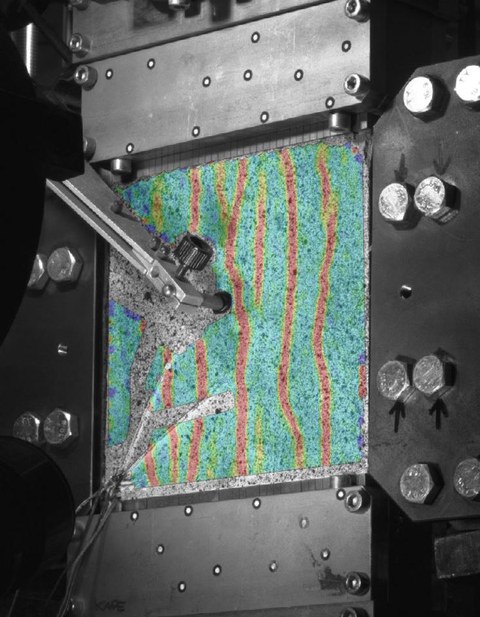

Photogrammetric image of the crack pattern

As research progresses, more design models are being developed for carbon reinforced concrete construction, which reduces market barriers and helps to establish the material. According to the tensile load-bearing behavior of carbon reinforced concrete, an extensive database and a large number of design approaches are available. The extent to which the material can be taken into account in areas subjected to compressive stress is still relatively open.

In the first project phase, the influence of carbon reinforcement in different configurations on the uniaxial compressive strength was investigated. The second phase described here deals with biaxial stress conditions. In addition to the tests with biaxial compressive stresses, which have already been completed and were intended to investigate the increase in concrete compressive strength known from steel reinforced concrete (RC), the focus is on the influence of a transverse tensile stress induced in addition to the compressive load. It is known from steel reinforced concrete construction that the associated cracking of the specimen or component leads to a significant reduction in the compressive forces that can be absorbed. This effect must be taken into account, among other things, in the design for shear and torsional stress.

During the tests, two loading paths are considered. In the case of proportional loading, both introduced loads, i.e. compressive and tensile forces, are increased in a fixed ratio. In the second scenario, a predefined tensile strain level in the reinforcement is approached and then the remaining load-bearing capacity under compressive stress is tested. With the help of resin blocks that enclose the carbon reinforcement in the load application areas, a sufficiently high tensile load can be applied to the specimens without causing bond failure of the reinforcement in the anchorage areas, even with the limited space available in the multi-axial testing machine. Different reinforcement configurations are investigated in order to define more precisely, among other things, the influence of the degree of reinforcement or of the impregnation typ, and the method of manufacture also varies.

Report from the annual report 2021

Carbon reinforced concrete comes under pressure

Experiment to test the tensile anchorage made of resin

While previous research in carbon concrete has mainly focused on the tensile load-bearing behaviour of the composite material, knowledge of the compressive load-bearing behaviour is still rudimentary. In the first project phase, initial investigations were carried out concerning uniaxial compressive loading and various influencing factors were identified. The degree of reinforcement, for example, was found to have a major influence on the compressive load-bearing capacity, while the production method played a subordinate role. For the application on the structural element level, these investigations are only suitable to a limited extent, as uniaxial loads only occur in rare cases. In reality, there are usually multi-axial stress conditions.

Therefore, the second project phase deals with the validation of the previous findings for stress conditions that are closer to those present in a structural element by using biaxial tests. A distinction is made between biaxial compressive loads and compressive loads with transverse tension in the reinforcement plane. While the former involves the increase in compressive strength in special cases in reinforced concrete structures, the reduction of compressive strength in cracked components, i.e. compression zones with transverse tension, is essential for shear force and torsion design. For both types of loading, investigations were planned on the influence of the number of layers, yarn diameter, mesh size, impregnation, fabrication and orientation of the reinforcement. The majority of the biaxial compression tests have been successfully completed this year.

For successful project implementation, the selection of suitable load introduction systems is of particular importance. For the compressive forces, proven loading principle could be used, but for the introduction of tensile stresses, the development of a new anchoring fixture is necessary due to the limited space in the testing machine. In addition to a uniform introduction of tensile stresses, care must be taken to ensure that the compressive stress distribution is impaired as little as possible. In preliminary investigations, different anchorage systems with clamps and bolts, anchorage areas made of resin and concrete, as well as additionally sanded reinforcements were considered.

Report from the annual report 2020

Carbon reinforced concrete under compression

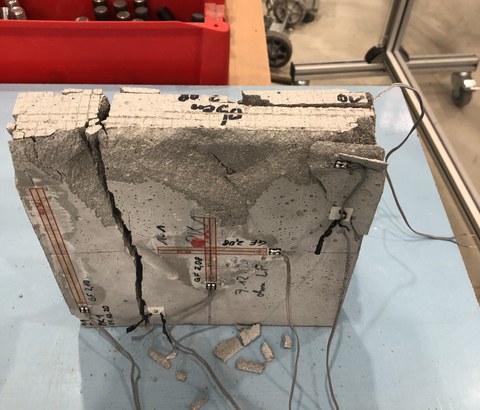

Specimen after testing

Many scientific areas of carbon concrete have been researched for years and show considerable progress in the regulation of the material. While models or modelling approaches exist e.g. bending, shear forces and torsion there is little knowledge about the behaviour of carbon concrete components under compressive loads. Initial findings under uniaxial compressive loading were obtained in the first phase of the project. The change of the manufacturing process, from cast specimens to hand-laminated insertion of the textile layers, led to a reduction of the load-bearing capacity. Furthermore, the influence of various parameters on the compressive strength of carbon concrete cubes was investigated, such as the spacing between the layers, the yarn thickness, the mesh size or a staggered arrangement of the textile layers. Based on these results, the focus of future research investigates to what extent these findings can be transferred to practically relevant components. A first step is being taken in this second phase of the project using multi-axial loaded carbon concrete disks with dimensions of 200 x 200 x 40 mm³. In most components, induced multi-axial stress states are present (for example due to torsional or shear loads).

For this reason, based on the knowledge from steel reinforced concrete constructions, possible increases in the load-bearing capacity due to compression-compression loads as well as reductions due to compression-tension loads are to be investigated. In addition to the structure of the textile reinforcement itself, which includes impregnation, layer spacing, mesh size and also the textile orientation, the manufacturing process and different stress ratios are to be varied during the tests. Based on the results from the second project phase, a numerical material model will be designed or the model from the first project phase will be extended. With the help of this model, virtual parameter studies can be conducted to plan large component tests in a further project phase and to be able to carry them out with as little effort as possible. Besides, these large-scale component tests are to verify the material model established at the end of this project phase.