SFB 528-B5: Grundlagen konstruktiver Bewehrungsdetails

Inhaltsverzeichnis

Projektdaten

| Titel | Title SFB 528 B5: Grundlagen konstruktiver Bewehrungsdetails | CRC 528 B5: Fundamentals of structural reinforcement detailing of textile reinforced concrete Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) / SFB 528 Zeitraum | Period 07/2009 – 06/2011 Leiterin | Project manager Dr.-Ing. Regine Ortlepp Bearbeiter | Contributor Dipl.-Ing. Enrico Lorenz M.Sc. |

siehe auch: hier

Bericht aus dem Jahrbuch 2011

Übergreifung textiler Gelege

Beim 4-Punkt-Biegeversuch

Zur Sicherstellung der Übertragbarkeit von anhand einaxialer Übergreifungsversuche konstruierter Stöße textiler Bewehrungen in Verstärkungsschichten aus Textilbeton wurden Biegeversuche an textilbetonverstärkten Stahlbetonplatten mit einem Übergreifungsstoß in Plattenmitte durchgeführt.

Die untersuchten Stahlbetonplatten waren 2,7 m lang, 60 cm breit und 10 cm dick. Sie besaßen in Längsrichtung eine untere Betonstahlbewehrung von 4 Stück Ø = 8 mm im Abstand von 15 cm. Als textile Bewehrung kamen praxistaugliche Carbontextilien mit Textilquerschnittsflächen von 169 mm²/m zum Einsatz.

Vor dem Verstärken mit Textilbeton wurden die Stahlbetonplatten sandgestrahlt, um eine ausreichend raue Verbundfuge zu erzeugen. Nach dem Vornässen der Stahlbetonplatten erfolgte der lagenweise Auftrag des Textilbetons mit der Ausbildung eines Übergreifungsstoßes in Plattenmitte. Die Tragfähigkeit der Platten wurde in 4-Punkt-Biegeversuchen mit einer Plattenspannweite von 2,50 m getestet.

In den Versuchen wurden für Textilzugfestigkeiten von 305 kN/m erforderliche Übergreifungslängen der textilen Bewehrung von 37 cm nachgewiesen. Dadurch konnten die bereits aus einaxialen Zugversuchen abgeleiteten Regeln und Bemessungsvorgaben zur Bestimmung von Übergreifungslängen und Ausbildung von Stößen in Verstärkungsschichten aus Textilbeton verifiziert werden. Angemerkt sei außerdem, dass die nachgewiesene Steigerung der Biegetragfähigkeit der mit lediglich einer Lage Textilbeton verstärkten Bauteile ca. 150 % im Vergleich zu den unverstärkt getesteten Stahlbetonplatten betrug.

Mit den im Rahmen des Teilprojektes B5 des SFB 528 durchgeführten experimentellen und analytischen Untersuchungen konnten wesentliche Grundlagen für eine rechnerische Bestimmung und sichere Ausführung von Übergreifungen textiler Bewehrungen innerhalb von Verstärkungsschichten aus textilbewehrtem Beton geschaffen werden.

Bericht aus dem Jahrbuch 2010

Übergreifungsstöße in Verstärkungsschichten aus Textilbeton

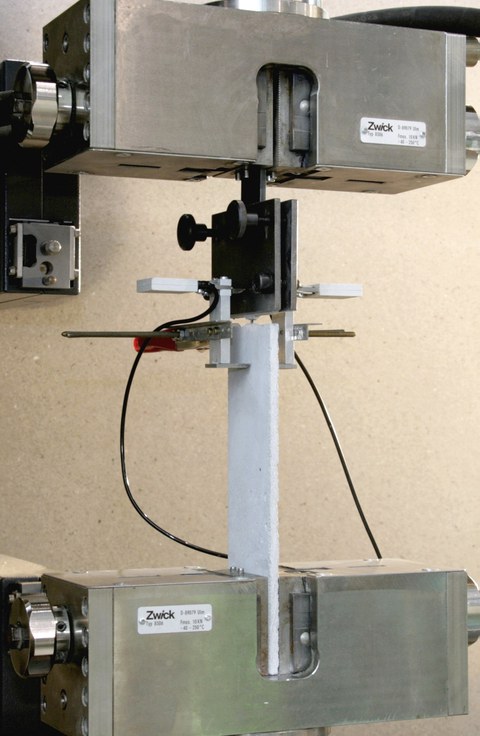

Zugversuch zur Bestimmung der erforderlichen Übergreifungslänge

Bei Verstärkungsmaßnahmen mit Textilbeton sind Übergreifungsstöße im Regelfall nicht zu vermeiden. Die Übergreifungsstöße in Textilbetonverstärkungen werden dabei aufgrund des flächigen Aufbaus der textilen Gelege sowie der lagenweisen Herstellung des Verbundwerkstoffs im Regelfall als zweilagige Stöße ausgeführt.

Zur experimentellen Untersuchung des Tragverhaltens solcher Stöße wurden Übergrei-fungsversuche in Anlehnung an die mittlerweile etablierten einaxialen Zugversuche – sogenannte Dehnkörperversuche – mit einem Übergreifungsstoß in Probenmitte durchgeführt.

Grundsätzlich können bei Textilbeton hinsichtlich eines Verbundversagens unterschiedliche Versagensarten auftreten. Im Bereich der Übergreifungsstöße konnten zwei verschiedene Mechanismen des Verbundversagens beobachtet werden. Zum einen kann es zu einem Versagen durch Auszug der Garne aus der Feinbetonmatrix kommen. Die zweite Variante ist ein Versagen durch Spaltrissbildung/Delamination innerhalb des Übergreifungsstoßes. Im Grenzzustand des Garnauszuges werden die Übergreifungslängen direkt durch die Größe der Verbundkräfte beeinflusst. Werden die übertragbaren Verbundkräfte zwischen Garn und Matrix größer, z. B. durch eine Erhöhung des Beschichtungsgrades der textilen Bewehrung, führt dies zu einer kürzeren erforderlichen Übergreifungslänge.

Die Neigung zum Delaminationsversagen wird von den Querzugkräften bestimmt, die durch die Krafteinleitung und Übertragung innerhalb des Übergreifungsstoßes entstehen. Wird die Zugfestigkeit des Betons in der Ebene der textilen Bewehrung überschritten, entstehen am Beginn des Übergreifungsstoßes zunächst kleine Spaltrisse, welche mit zunehmender Last immer weiter in den Übergreifungsbereich hineinwandern und anschließend zum Versagen führen können.

Anhand der Versuchsergebnisse und der Betrachtung der Versagensmechanismen wurde ein Modell entwickelt, mit dem die erforderlichen Übergreifungslängen im Grenzzustand des Garnauszuges zutreffend prognostiziert werden können. Auch wurden umfassende analytische Untersuchungen zur Vorhersage der Delaminationsneigung durchgeführt, die ebenfalls eine gute Übereinstimmung mit den versuchstechnisch ermittelten Werten ergab. Außerdem konnten anhand der Versuche und Beobachtungen gezielt Anforderungen zur weiteren Verbesserung und Optimierung des Textil-Matrix-Systems definiert werden, die derzeit Erfolg versprechend umgesetzt werden.

Bericht aus dem Jahrbuch 2009

Konstruktive Bewehrungsdetails

Textilauszugsversuch

Für die Instandsetzung und Verstärkung von Betonbauteilen mit Textilbeton hat die Verankerung der textilbewehrten Feinbetonverstärkungsschicht am Altbetonuntergrund eine wesentliche Bedeutung. Dabei können im Hinblick auf ein Verbundversagen der Endverankerungsbereiche vier verschiedene Versagensmechanismen maßgebend werden. Im Rahmen des Teilprojektes C1 wurden diesbezüglich umfangreiche Untersuchungen zur Erforschung der drei flächigen Versagensarten durch Delaminations- und Altbetonversagen sowie der Zerstörung der Verbundfuge zwischen Fein- und Altbeton durchgeführt. Besonders bei Textilien aus Carbonfasern werden jedoch aufgrund der sehr hohen Garnzugfestigkeiten die erforderlichen Lasteinleitungslängen meist durch den Auszug der Filamentgarne aus dem Feinbeton bestimmt. Daher erfolgten im Rahmen des Teilprojektes B5 Untersuchungen zur Klärung des Versagenskriteriums durch Garnauszug.

Dazu wurde im ersten Schritt zur experimentellen Untersuchung des Verbundverhaltens zwischen Garnoberfläche und Feinbetonmatrix ein Versuchsaufbau zur Durchführung von Textilauszugsversuchen mit kurzen Einbindelängen an beschichteten textilen Bewehrungsstrukturen entwickelt. Anhand der in den Textilauszugsversuchen experimentell bestimmten Kraft-Rissöffnungs-Beziehungen erfolgte anschließend eine analytische Modellierung der jeweiligen Verbundspannungs-Schlupf-Beziehungen der textilen Bewehrung.

Mit Hilfe eines separaten Modells konnte im dritten Schritt anhand der ermittelten Verbundspannungs-Schlupf-Beziehungen die zur Verankerung einer entsprechenden Kraft F erforderliche Verankerungslänge berechnet werden.

Zur Überprüfung der analytischen Modellierungen und der getroffenen theoretischen Annahmen wurden unabhängige experimentelle Versuche zur Bestimmung der Verankerungslängen durchgeführt. Es konnte eine gute Übereinstimmung der berechneten mit den versuchstechnisch bestimmten Verankerungslängen festgestellt werden.

Mit Hilfe der gefundenen Zusammenhänge ist nun im Gesamtkontext unter Beachtung der Ergebnisse für flächige Versagensarten eine umfassende rechnerische Bestimmung der Endverankerungslängen textilbewehrter Verstärkungsschichten aus Feinbeton möglich.

Neben der Vorhersage der erforderlichen Verankerungslängen können die ermittelten textilspezifischen Verbundkennwerte weiterhin zur Berechnung von Übergreifungslängen sowie zur Vorhersage von Rissabständen und Rissweiten verwendet werden.