SFB 528-D1 (II): Instandsetzung und Verstärkung von Stahlbetonbauteilen für Querkraft

Inhaltsverzeichnis

Projektdaten

| Titel | Title SFB 528-D1: Instandsetzung und Verstärkung von Stahlbetonbauteilen für Querkraft | CRC 528-D1: Maintenance and shear strengthening of Reinforced Concrete Members Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) / SFb 528 Zeitraum | Period 01/2006 – 03/2009 Leiter | Project manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Bearbeiterin | Contributor Dipl.-Ing. Anett Brückner |

Bericht aus dem Jahrbuch 2009

Textile Bewehrung zur Querkraftverstärkung

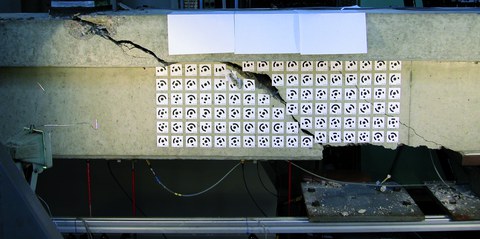

Querkraftversuch an einem Plattenbalken

Bei der Bemessung von Ingenieurbauwerken kann aufgrund der langen Lebensdauer von durchschnittlich 80 bis 100 Jahren nicht jede Nutzung und Beanspruchung vorhergesehen werden. Unplanmäßige Beanspruchungen sowie unzutreffende Berechnungsannahmen, Bauausführungsfehler oder Umwelteinflüsse können zu Schäden an Bauteilen führen. Soll die Bausubstanz erhalten werden, sind Sanierungen oder Verstärkungsmaßnahmen erforderlich.

Die Querkrafttragfähigkeit eines Bauteiles kann durch verschiedene Maßnahmen gesteigert werden. Eine Möglichkeit ist die Verstärkung mit textilbewehrtem Beton. Der textilbewehrte Beton kombiniert die Materialeigenschaften des stahlbewehrten Spritzbetons mit den geometrischen Eigenschaften von geklebten Bewehrungen. Das bedeutet, auch der textilbewehrte Beton hat die stahlbetontypischen Eigenschaften, die Dicke der Verstärkung erinnert jedoch eher an geklebte Bewehrungen. Möglich werden die geringen Schichtdicken durch den Einbau nichtkorrosiver Bewehrungen aus ARGlas, Carbon oder anderen Hochleistungsfasern in einer Feinbetonmatrix mit einem Größtkorn von 1 mm. Der textilbewehrte Beton wird in wechselnden Lagen aus Feinbeton und textiler Bewehrung aufgebracht. Die Gesamtdicke der Verstärkung liegt abhängig vom erforderlichen Bewehrungsgrad bei 1 bis 2 cm.

Die experimentellen Untersuchungen an Bauteilen mit praxisrelevanten Querschnitten haben gezeigt, dass die Tragfähigkeit eines Stahlbetonbauteils durch eine textilbewehrte Querkraftverstärkung erheblich gesteigert werden kann. Besonders effektiv ist die Verstärkung, wenn die textile Bewehrung und die vorhandene Stahlbewehrung additiv zusammenwirken. Die Traglaststeigerung gegenüber dem unverstärkten Bauteil würde in diesem Fall der Querkrafttragfähigkeit der zusätzlichen Bewehrung entsprechen. Tatsächlich ist die Traglaststeigerung aber geringer, da die aufgebrachte Verstärkungsschicht die Steifigkeitsverhältnisse im Steg verändert. Die Auswirkungen auf die Steifigkeitsverhältnisse konnten durch Verformungsmessungen an den Stegseiten nachgewiesen werden (Photogrammetrie).

Die Verankerung der Querkraftverstärkung erfolgte in allen Versuchen außerhalb der rechnerischen Biegedruckzone. Die Verstärkungsschicht war allein über den Haftverbund an den Stahlbetonquerschnitt angeschlossen, um die Tragfähigkeit der Verbundfuge zu ermitteln. Das Versagen des Haftverbundes wurde durch Messung der Relativverschiebungen zwischen Steg und Verstärkungsschicht festgestellt.