Lokales Fressen und Schädigungsfortschritt der Zahnflanke durch Grauflecken sowie Grübchen

|

Volltitel: |

Lokales Fressen und Schädigungsfortschritt der Zahnflanke durch Grauflecken sowie Grübchen (nach FVA-Vorhaben 411, 516 und 519) |

| Laufzeit: |

10/2013 – 02/2017 |

|

Bearbeiter: |

Dipl.-Ing. (FH) Marcus Merder, |

| Förderer: |

Forschungsvereinigung Antriebstechnik (FVA) |

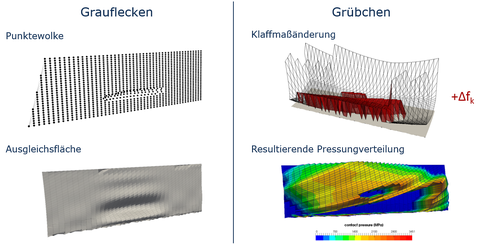

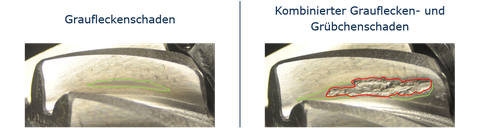

| Anliegen: | Grauflecken und Grübchen sind charakteristische Ermüdungsschäden auf der Zahnflanke, welche zu einer Veränderung der Flankenform führen. In der Folge verändert sich die Last- und Pressungsverteilung, wodurch die Schadensmodi und der Schadensverlauf maßgeblich beeinflusst werden können. Bisher wird die Tragfähigkeitsberechnung in BECAL lediglich anhand der Soll-Topographie der Flanke durchgeführt. Ziel dieses Vorhabens ist es die durch Schädigung fortwährend veränderliche Flankenform in die BECAL-Simulation einzubeziehen, um so eine realistischere Abbildung der Flankentragfähigkeit zu erhalten. Zusätzlich wird die lokale Fresstragfähigkeit nach KLEIN [FVA519] als Ergänzung des Tragfähigkeitsteils in BECAL implementiert. |

| Vorgehensweise: |

Die Grundlage der Simulation bilden die Berechnungsansätze zur Ermittlung der lokalen Tragfähigkeiten hinsichtlich Grübchen und Grauflecken nach Wirth (FVA411) und Hombauer (FVA516). Weiterhin wird ein Ansatz zur Berechnung der lokalen Flankenformänderung nach Hombauer (FVA516) verwendet. |

| Ergebnis: | Die Simulation des Schädigungsfortschritts mithilfe der Software BECAL ist prinzipiell möglich und liefert unter gewissen Einschränkungen sehr gute Ergebnisse. In Hinblick auf eine kommerzielle Nutzung der Schädigungssimulation und um die Ergebnisse dementsprechend statistisch abzusichern müssten jedoch weitere Versuche und Validierungsrechnungen durchgeführt werden. |