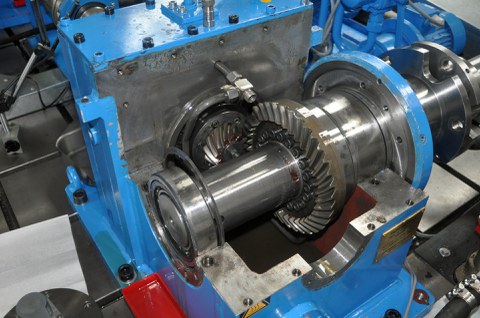

Bevel gears

|

Full title: |

Bevel gear drives |

| Abstract: |

In drive technology, bevel gears still represent the most important machine element for a torsionally rigid, angular power transmission. Typical applications of bevel gears are axle drives of vehicles, transmissions in helicopters, steerable thrusters and industrial gear units. |

|

Objective: |

Bevel gears are used preferably when torque and rotational speed, as well as the direction of the power flow, need to be changed. Bevel gears are highly stressed machine elements meetings high requirements regarding power density, noise and manufacturing efficiency. Thus, they are widely used in automotive engineering, railway vehicles, aircrafts, marine and industrial transmissions. The design of bevel gears aims at the improvement of efficiency and power density, which is bound to an increase of load capacity. To meet these requirements, the software package BECAL (BEvel gear CALculation) was developed by the TU Dresden’s Institute of Machine Elements and Machine Design (IMM) and Institute of Geometry for the Forschungsvereinigung Antriebstechnik e.V. (FVA). BECAL includes gear design and load capacity analyses by a complex tooth contact simulation of helical and spiral bevel gears as well as hypoid gears. BECAL is continuously maintained and developed at IMM. |

| Contacts: |

Dr.-Ing. Stefan Schumann |

| Current projects: |

|

| Completed projects: |

|

| Testing technology: |

|