Implants

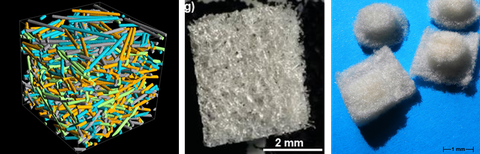

Defect-adjusted, complex, porous structure made from short fibers, for bone replacement, developed by means of simulation-based, additive “net shape nonwoven” (NSN) method

Fibers as basic building blocks for implants are creating an increasingly important focus in medicine and healthcare economy. The adjustable mechanical properties of the flexible textile materials, and the outstanding ratio of surface and volume are the primary reasons for increasing use in medical applications. The native structure of various organs like bones and blood vessels, as well as fibrillar structures in the human body, like muscles, sinews, and tendons, can be imitated most suitably using textile structures.

ITM scientists and partners from various hospitals and medical companies are researching along the entire value chain, from biomaterial to (pre-)clinical trials of fiber-based implants, to develop new products and establish them in medical applications. Current R&D work is focused on simulation-assisted technology development for the production of individual, application-specific, complex implants for the regeneration of hard and soft tissue defects by means of various textile techniques like weaving, braiding, knitting, and warp-knitting, electrostatic flocking, and the increasingly important additive production methods.

Three-dimensional cell carrier structures (scaffolds) for tissue engineering, based on the NSN method

The ITM can offer the following competences in this field:

- customized product development from polymer to implants used as:

- absorbable and non-absorbable biomaterials,

- cell carriers for regenerative medicine,

- functional replacement of natural tissues (e.g. stents, vessel prostheses, cardiac valves, bone and cartilage implants),

- force transfer elements and plastic reinforcements in the form of tendon, ligament, and joint replacements, as well as

- tissue support, for instance for ligament augmentation and hernia fixation, and auxiliary materials (e.g. sutures, abdominal wall closures),

- modeling and simulation of fiber-based structures and processes,

- realization of load-adapted, near-net shape, and material-efficient structures,

- development and construction of unique (miniaturized) machines and additive production methods,

- biosensor development, and setup of testing and measuring rigs,

- chemicals, physical and cellular-biological analyses of the developed biomaterials, scaffolds, and implants, and

- quality managements for the production of medical products.

© ITM/TUD

© ITM/TUD

© ITM/TUD

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr. Michael Wöltje

Research Group Leader Biomaterials and Medical Technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Breitscheidstr. 78, House D, Room 1.1.13

01237 Dresden