Thermoplastic composites

ITM-made thermoplastic fiber-reinforced composite materials for lightweight design applications

Thermoplastic fiber-reinforced composite materials for lightweight design applications are combination of requirement-adapted, fiber-based materials with a thermoplastic matrix system like polypropylene (PP), polyamide (PA) or polyether ether ketone (PEEK). The properties of the plastic matrix results in special advantages for their use in fiber-reinforced composite materials, including:

- high ultimate strain of the matrix,

- excellent impact behavior (energy absorption in crash cases),

- unlimited storability of prepregs (pre-impregnated semi-finished fiber products) and organic sheets,

- weldability and

- postformability, and

- short cycle times for a large-series component production.

One special challenge for the production of highly-loaded thermoplastic fiber-reinforced composite materials is to realize a thorough impregnation and wetting of all reinforcement fibers, caused by their high viscosity.

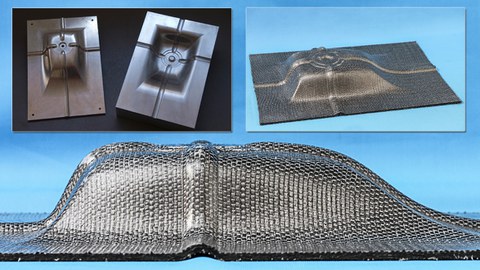

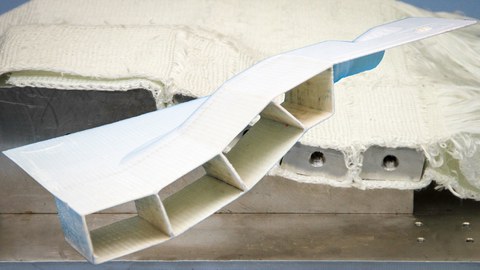

One approach of the ITM for the realization of long-fiber-reinforced thermoplastic components is based on the development and realization of hybrid yarns flexible adjusted to the requirements, as a combination of high-performance reinforcement fibers and a variety of thermoplastic matrix fibers like carbon/PEEK or glass fiber/polypropylene. A specific adjustment of processing properties of the hybrid yarns to the requirements of the textile production processes allows the production of load-adapted textile reinforcement-structures with complex 2D and 3D geometries. The good, homogeneous mixture of reinforcement and matrix components in the hybrid yarns shortens the flow paths of the matrix in the consolidation phase of any thermopressing processes. The thorough impregnation achieves an extensive activation of all reinforcement fibers for load transfer within the component.

The ITM has gained broad knowledge regarding the development and realization of simulation-based process chains for the production and processing of textile structures for thermoplastic component structures, and the specific adjustment of material and component properties. This advantages allows the ITM to foster and support the design of component production processes for the production of organic sheets and/or 2D and 3D fiber composite components.

ITM-made thermoplastic fiber-reinforced composite materials for lightweight design applications

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Matthias Overberg

Generative 3D technologies for integration and preforming

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

George-Bähr-Straße 3c, Zeunerbau, Room 111

01069 Dresden