Polymer and fiber technology

Solvent wet spinning plant by Fourné Polymertechnik GmbH for research and development in fiber technology (man-made fibers, polyacrylonitrile, biological-origin source, chitosan, functional fibers, polyurethane) © Martin Kirsten

The technologies available at the ITM allow the spinning of a wide variety of chemical fibers. Apart from spinning biological fibers (chitosan and gelatin, collagen), piezo-sensitive fibers (PVDF), or shape-memory fibers (Polyurethane), the modular, flexible wet spinning plant by Fourné Polymertechnik GmbH is also used to spin high-performance fibers. These are based on organic and non-organic polymers and pre-polymers. Particularly the production of high-purity polyacrylonitrile fibers as a carbon fiber precursor is an important task.

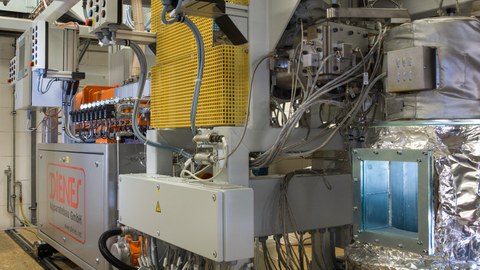

Two-component extrusion melt spinning plant (DIENES Apparatebau GmbH) for the spinning high-performance fibers (incl. polypropylene, polyamide, polyethylene terephthalate, polyimide-amid, PEEK) © Mirko Krziwon

To broaden the ITM’s competences in the field of fiber spinning, the Excellence efforts of TU Dresden gave the institute an opportunity to install a two-component extrusion melt spinning plant designed in co-operation with manufacturer DIENES Apparatebau GmbH. The plant enables the production of monofilaments and multifilament fibers with various finenesses and filament counts, and the combination of several polymers in a single filament at defined geometries during spinning, thus creating core/sheath, side-by-side, or island-in-the-sea fiber setups. The ITM has been planning to produce requirement-adapted carbon fiber precursors like lignin or functionalized PAN by means of melt spinning.

Carbonization plant by SGL Carbon SE for the development of customized carbon fibers

To research and develop carbon fibers, the ITM and the ILK (Institute of Lightweight Engineering and Polymer Technology) have access to a complete stabilization and carbonization plant. Based on the modular and flexible plant technology regarding defined temperatures, gas flows, thread courses and tensile tensions, structure formation mechanisms are examined with due regard to process parameters. The results allow the customization and requirement-adapted use of carbon fibers in future and high-tech areas, including functional energy storage systems and textile construction with carbon concrete.

To research and develop carbon fibers, the ITM and the ILK (Institute of Lightweight Engineering and Polymer Technology) have access to a complete stabilization and carbonization plant. Based on the modular and flexible plant technology regarding defined temperatures, gas flows, thread courses and tensile tensions, structure formation mechanisms are examined with due regard to process parameters. The results allow the customization and requirement-adapted use of carbon fibers in future and high-tech areas, including functional energy storage systems and textile construction with carbon concrete.

The research and development efforts are based on fiber characterizations by means of extensive analytical methods like RE and TE microscopy, Fourier transform infrared spectroscopy (FTIR), themoanalytics (DSC and TGA), and measurement of tensile tension and rigidities at defined temperature.

The existing plant technology for fiber spinning at the ITM is widely used by the Dresden-based research centers founded in 2016:

- RCCF - "Research Center Carbon Fibers Saxony“ and

- HP-FIBRE-STRUCTURES - High Performance Fibers and Structures and Development of Textile Machinery".

Both centers aim to research and develop customized carbon fiber precursors.

Image film about the Research Center Carbon Fibers Saxony (RCCF) © significant.pictures

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.Ing. Lukas Benecke

Research Group Leader Polymer Syntheses and Fiber Technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Breitscheidstr. 78, House D, Room 1.1.14

01237 Dresden