Stability of carbon-reinforced concrete

Table of contents

Project data

|

Titel | Title |

Report from the annual report 2023

About Bending and Breaking

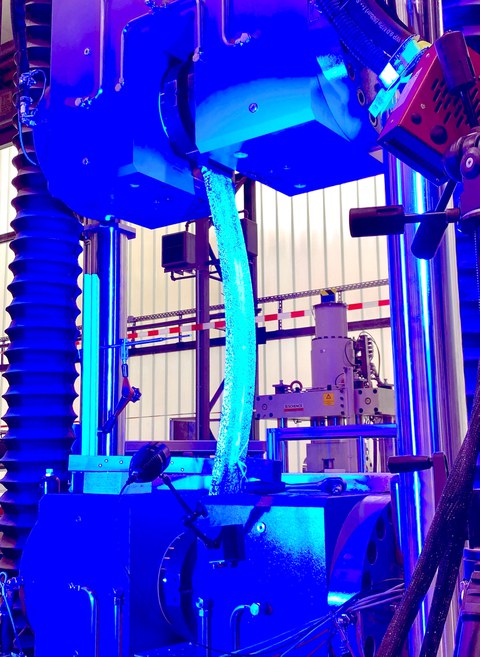

Uniaxial compression test on disk-shaped specimen made of carbon-reinforced concrete

In 2023, the focus was on hinged samples with lower slenderness ratios λ. Compression tests on stocky, disk-shaped specimens aimed at characterizing the composite carbon-reinforced concrete (CRC) itself. The observed stress-strain behavior was used to derive two relevant slenderness ratios for the further stability tests: on the one hand the point of theoretical transition from elastic to plastic buckling at λ ≈ 85 and on the other the transition point from stability to material failure at a slenderness of λ ≈ 60. To examine the behavior under combined bending and normal force, tests with load eccentricities of 2 and 4 mm were carried out in addition to centric load application.

Using digital image correlation, it was demonstrated for all slenderness ratios that the buckling figures of the deflected specimens corresponded to a sinusoidal curve up to the point of the sudden failure, confirming the suitability of the hinged support construction. Failure manifested itself either by an abrupt, great deflection at higher slenderness ratio or greater influence of the bending moment or by fracture of the specimen due to higher influence of the normal force and at lower slenderness ratios. The reference samples exhibited a clear deviation from Euler’s theory, which can be attributed to the phenomenon of plastic buckling. As expected, an increase in both load eccentricity and slenderness ratio resulted in a decrease in the maximum bearable stress.

The results underline the indispensability of considering these parameters when designing thin-walled structures made of textile-reinforced concrete. Moment-normal force interaction curves will now be used to examine whether the failure is indeed a stability problem or a stress problem according to second-order theory, or if the failure mechanism depends on the mentioned parameters.

Report from the annual report 2022

Buckling tests on carbon-reinforced concrete

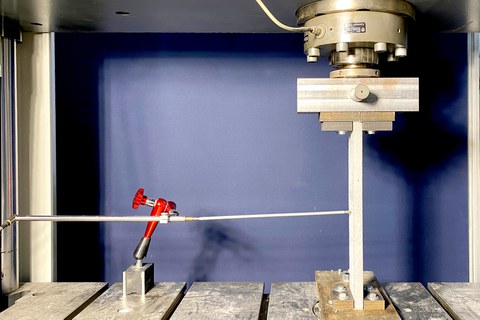

CRC specimen after buckling failure

With the high-performance composite material carbon-reinforced concrete, it is possible to construct load-bearing structures that are slender and thus material-saving. However, as the slenderness increases, so does the need to analyze the stability behavior, which is generally of secondary importance in conventional reinforced concrete construction. In that regard, it must be taken into account that these structures have a higher sensitivity to structural and geometric imperfections.

Within the scope of the research project, buckling tests were carried out on slender, articulated specimens with a rectangular cross-section, whereby the deformation behavior under uniaxial compressive loading was observed with a photogrammetry system. The aim of the tests was to gain first insights into the effects of purposefully applied initial imperfections on the stability of the carbon concrete specimens. The focus of the investigations was on the variation of manufacturing-related imperfections such as the position of the textile as well as the grain distribution of the concrete in the cross-section, but also imperfections in the load application.

The first challenge for a successful execution of the tests was to develop a suitable system for the load application that allows to apply a centric as well as planned eccentric load. For this purpose, small, tapered steel sections were fabricated in three different configurations. They need to be attached to the two contact surfaces of the specimens. The tips are then inserted into the notch of a steel block clamped at the top and bottom in the testing machine.

In addition to the analysis of the failure process, the results of the buckling tests were compared to the ideal buckling load according to Euler and to the stress equation according to second-order theory which showed good agreement with the experimental results. The specimens tested so far had a uniform slenderness of λ ≈ 125. Further experiments are planned to investigate the already mentioned as well as other imperfection influences on specimens with lower slendernesses.

The subproject C04 is executed in cooperation with the Institute of Concrete Structures of RWTH Aachen University, where the focus is on the detailed study of quasiductility.

Report from the annual report 2021

Imperfections and stability

Experimental setup for initial tests to investigate stability behaviour

Carbon-reinforced concrete is a composite material made of high-performance materials that allow creation of structures that are highly load-bearing but slender and material-efficient at the same time. Due to the significant reduction in thickness of the components compared to structures made of conventional reinforced concrete, the issue of stability in carbon concrete becomes more important. Especially the increased sensitivity of filigree structures to internal and external imperfections such as geometric deviations or inhomogeneities of the cross-section must be taken into account.

The research project is therefore initially addressing the question of which parameters influence the stability behaviour of slender carbon concrete components and to what extent. Experimental and numerical investigations of planar and curved structural elements of different sizes are planned to investigate the influence of manufacturing-related imperfections, such as material distribution (position of the reinforcement within the cross-section, grain distribution in the concrete over the cross-section thickness) and geometry (deviations in the component thickness, pre-curvatures, e.g. as a result of non-uniform shrinkage), but also imperfections of the load introduction. The subjects of the current stability investigations are buckling tests on small-sized, slender specimens, where the geometrically and physically non-linear deformation behaviour under uniaxial compressive loading is observed.

Subproject C04, which is being worked on in cooperation with the RWTH Aachen University, pursues the overarching objective of developing practical construction principles and design rules for thin-walled carbon concrete components that consistently capture the closely related aspects of stability and quasi-ductility, given the interaction between material behaviour and shape. The project partner in Aachen is investigating how ductile load-bearing behaviour can be achieved in the composite carbon concrete, which consists exclusively of brittle material components.

Report from the annual report 2020

Stability of carbon-reinforced concrete components

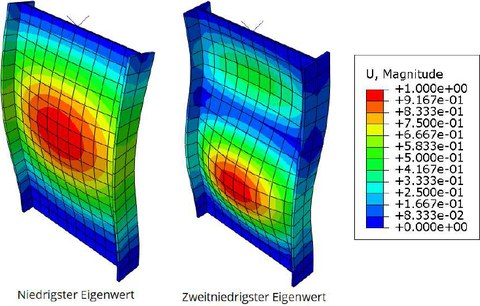

First and second eigenvalue in the FEM analysis

The predominant advantage of carbon-reinforced concrete structures is associated with slimmer structural members and smaller cross-sectional dimensions compared with steel reinforced solutions. Consequently, carbon-reinforced concrete structures allow a reduction in the amount of concrete and further the use of resources. On the other hand, the opportunity to build more slender structures increases the sensitivity to stability failure. Also, carbon fibres are considerably more brittle than reinforcing steel, leading to a significant reduction of the deformation capacity. The design criteria and recommendations developed for steel-reinforced concrete structures are either not applicable or need to be adapted, especially concerning the brittle behaviour of carbon and the use in composite structures.

The C04 project intends to provide the engineering background for the design of slender, structural carbon-reinforced concrete members, which are sensitive to stability failure and serve as the basis for practical solutions, design criteria and recommendations. The main focus lies on the significantly reduced deformation capacity and the correlation with stability, quasi-ductility and cubage. Project C04 is a cooperation between the RWTH in Aachen and Technische Universität Dresden.

The project members belonging to the Technische Universität Dresden are predominantly responsible for the stability topic. The stability behaviour is affected by geometrical deviations (geometrical imperfections) on the one hand and structural imperfections on the other. In this regard, both calculations and tests will be accomplished. At the moment, we are focussing on structural imperfections caused by the concrete inhomogeneity, location of the reinforcement, fabrication issues as well as load-dependent imperfections.