Praxistaugliche Verankerungs- und Übergreifungslösungen für FVK-Bewehrung

Inhaltsverzeichnis

Projektdaten

|

Titel | Title |

Bericht aus dem Jahrbuch 2022

Verankern, aber richtig!

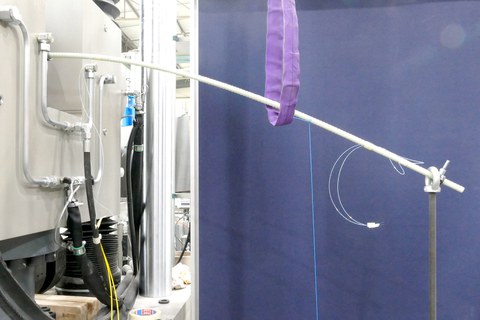

Biegeversuch an einer Platte mit übergreifenden FVK- und Stahlstäben

Dank ihrer hervorragenden Materialeigenschaften ermöglichen Faserverbundkunststoffe (FVK) besonders effiziente, leichte und wirtschaftliche Tragstrukturen. Durch die hohe Zugfestigkeit, Korrosionsbeständigkeit und sehr geringe Wärmeleitfähigkeit eignen sich FVK-Bewehrungen besonders gut für dünne, hochbeanspruchte Betonkonstruktionen, aber auch für Anwendungen in aggressiver Umgebung. Um das Potential dieser innovativen Werkstoffe vollständig nutzen zu können, sind experimentell verifizierte Kenntnisse zum Verbundtragverhalten erforderlich.

Dazu wurden in diesem Projekt zunächst Auszugversuche an verschiedenen FVK-Bewehrungen und auch an Stahlbewehrung durchgeführt. Als Ergebnis wurden die Kraft-Schlupf-Beziehungen für die geprüften Varianten ausgewertet und verglichen. Um das Verbundverhalten der FVK-Stäbe weiter zu analysieren, wurden zudem nichtlineare numerische Untersuchungen mit der FE-Software ANSYS durchgeführt. Im Fokus der Berechnungen standen dabei das lokale Verformungsverhalten des Betons sowie die inneren Spannungszustände und die innere Rissbildung.

Darüber hinaus wurde das Tragverhalten an Platten mit übergreifender FVK-Bewehrung und herkömmlichem Bewehrungsstahl experimentell ermittelt. In diesem Zusammenhang wurden verschiedene Arten von Versuchen realisiert: Zugversuche an reinen FVK- und an Stahlstäben zur Bestimmung der Materialeigenschaften wie Zugfestigkeit und E-Modul sowie Übergreifungsversuche zwischen FVK- und Stahlstäben, um den Lastabtrag im Übergreifungsbereich zu untersuchen. Bei allen Versuchen wurden quasikontinuierliche faseroptische Dehnungsmessungen herangezogen, um die Dehnungsentwicklung in den Stäben zu quantifizieren. Als Begleituntersuchungen wurden Verbundversuche mit langer Verbundlänge durchgeführt, um die Eignung verschiedener faseroptischer Sensoren und verschiedener Applikationsvarianten für die Übergreifungstests abzuschätzen. Aus diesen Versuchen ging hervor, dass die kombinierte Übergreifung von FVK-Stäben und Bewehrungsstahl die Tragfähigkeit nicht negativ beeinflusst, sondern zu höheren Tragfähigkeiten als bei den Versuchskörpern mit übergreifendem herkömmlichem Bewehrungsstahl führt.

Bericht aus dem Jahrbuch 2021

Verankerung von FVK-Bewehrung

Biegeversuch an FVK-Stäben mit FOS

Faserverbundkunststoffe (FVK) ermöglichen im Bauwesen besonders effiziente, leichte und wirtschaftliche Bauteile. Durch ihre hohe Zugfestigkeit, Korrosionsunempfindlichkeit und geringe Wärmeleitfähigkeit können FVK-Bewehrungen insbesondere bei schlanken, hoch beanspruchten Betonbauteilen sowie in aggressiver Umgebung sinnvoll eingesetzt werden. Um das Potential dieser innovativen Werkstoffe im Bauwesen vollständig nutzen zu können, sind experimentell verifizierte Kenntnisse zum Verbundtragverhalten erforderlich. Zur Verankerung von FVK-Spanngliedern wird zudem eine Technologie benötigt, die das schnelle Verankern auf der Baustelle zulässt. In diesem Forschungsvorhaben werden daher neuartige, praxistaugliche Verankerungsmöglichkeiten für Bewehrung und Spannglieder aus FVK entwickelt. Die Grundlage dafür bilden experimentelle und numerische Untersuchungen.

Um das Verbundverhalten von FVK-Bewehrung und Beton im Rahmen der experimentellen Untersuchungen zu bewerten, wird neben der Verbundspannungs-Schlupf-Beziehung die Dehnungsentwicklung im Stab betrachtet. Zur Dehnungsmessung werden dabei faseroptische Sensoren (FOS) auf Basis von Rayleighstreuung verwendet. FOS sind bereits in großem Umfang auf Stahl- und Betonoberflächen eingesetzt worden. Für die Applikation auf FVK-Stäben gibt es dagegen nur wenige Untersuchungen. Mit dem Ziel Material- und Handlungsempfehlungen für einen zuverlässigen Einsatz von FOS auf FVK-Stäben zu formulieren, wurden daher Zug- und Biegeversuche an reinen FVK-Stäben sowie Ausziehversuche mit FOS durchgeführt. Es wurden zwei Arten von Fasercoatings (mit Acrylat- und Polyimidbeschichtung) und zwei Arten von Klebstoffen (Epoxid und Cyanacrylat + Silikon) zur Applikation verwendet, sodass insgesamt vier Fasercoating-Klebstoff-Kombinationen untersucht wurden. Zudem wurde die Art der Applikation (Klebung in einer Nut und auf der Staboberfläche) variiert. Mit den Untersuchungen wurde die Plausibilität und Zuverlässigkeit der verschiedenen Kombinationen geprüft, die Verbundspannungen zwischen den Stäben und dem Beton in den Ausziehversuchen gemessen und die Biege- und Zugfestigkeit der FVK-Stäbe ermittelt. Die Ergebnisse dieser Untersuchungen dienen als Grundlage für die weiterführenden Vier-Punkte-Biegeuntersuchungen an Betonbauteilen mit FVK-Bewehrung bzw. -spanngliedern.

Bericht aus dem Jahrbuch 2020

Gut verankert

Numerische Untersuchung von Verankerungen von FVK-Stäben

Faserverbundkunststoffe (FVK) werden in vielen Bereichen der Technik äußerst erfolgreich eingesetzt und ermöglichen auch im Bauwesen besonders effiziente, leichte und wirtschaftliche Bauteile. So zeichnen sich FVK-Bewehrungen durch hohe Zugfestigkeiten, Korrosionsunempfindlichkeit und sehr geringe Wärmeleitfähigkeit aus. Insbesondere bei schlanken, hoch beanspruchten Betonbauteilen sowie in aggressiver Umgebung können FVK-Bewehrungen sinnvoll eingesetzt werden.

Um das Potential dieser innovativen Werkstoffe nutzen zu können, sind experimentell verifizierte Kenntnisse zum Verbundtragverhalten erforderlich, um Verankerungs- und Übergreifungslängen sicher und wirtschaftlich bemessen zu können. Zur Verankerung von FVK-Spanngliedern wird zudem eine Technologie benötigt, die das schnelle Verankern auf der Baustelle zulässt. Eine sichere und effiziente Verankerung von (vorgespannten) FVK-Bewehrungen ermöglicht es weitere Anwendungsgebiete für diese korrosionsbeständige und äußerst zugfeste Art des Bewehrens zu erschließen.

In diesem Forschungsvorhaben werden daher neuartige, praxistaugliche Verankerungsmöglichkeiten für Bewehrung und Spannstäbe aus FVK entwickelt. Hierzu werden experimentelle und numerische Untersuchungen an Bewehrung aus glasfaserverstärkten Kunststoffen (GFK) sowie an Spannstäben aus kohlefaserverstärkten Kunststoffen (CFK) durchgeführt.

Bei der schlaffen GFK-Bewehrung liegt der Fokus auf der Untersuchung und Optimierung des Verbundverhaltens, um vergleichsweise kurze Verankerungs- und Übergreifungslängen sicher realisieren zu können. Verglichen mit Verankerungs- und Übergreifungsbereichen von Stabstahlbewehrung sind diese häufig überdimensioniert, was einen wirtschaftlichen Einsatz von FVK-Bewehrung und mitunter die konstruktive Durchbildung erschwert.

Für CFK-Spannglieder wird eine neuartige lokale Verankerung durch einen Polymerwerkstoff entwickelt und untersucht. Der Einsatz herkömmlicher Stahlkeile, wie sie bei der Verankerung von Stahlspanngliedern eingesetzt werden, ist aufgrund der Querdruckempfindlichkeit anisotroper CFK-Spannstäbe nicht effizient möglich. Vor diesem Hintergrund wird ein „weicherer“ Polymerwerkstoff zum Verkeilen der Stäbe eingesetzt und die Querpressung an der Verankerungsstelle soweit reduziert, dass ein Versagen der Stäbe ausgeschlossen werden kann. Gleichzeitig kann eine hohe Verankerungswirkung erzielt und eine hohe Praktikabilität der Verankerungstechnologie auf der Baustelle gewährleistet werden.