Modelling steel fiber reinforced concrete composite under impact

Table of contents

Project data

|

Titel | Title |

Report from year book 2019

NUMERICAL MODELING OF DYNAMIC SPALLING ON PLAIN CONCRETE AND SFRC COMPOSITE

Test-specimen after a spallation test in the split Hopkinson bar

One of the direct tests to measure the dynamic tensile strength of brittle materials such as concrete, mortar and rock at medium strain rate is the spalling test using the modified split Hopkinson pressure bar facility (MSHPB). The setup consists of a projectile, an incident bar and the specimen. After the impact of the projectile, a compressive stress wave is generated and travels through the incident bar. When it reaches the specimen, part of it is transmitted into the specimen, while the rest is reflected back to the Hopkinson bar due to the impedance difference. When the transmitted compressive stress wave arrives at the free end of the specimen, it is reflected as a tensile stress wave. It leads to the fracture of the concrete specimen when the stress of the reflected tensile wave is equal to the dynamic tensile strength.

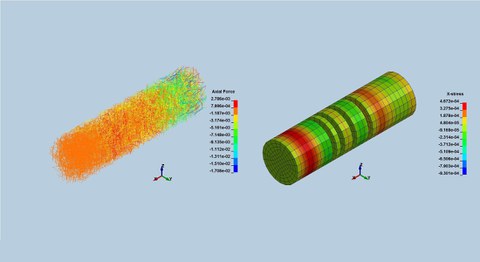

A three-dimensional finite element model of the complete modified split Hopkinson pressure bar (MSHPB) was defined, including the steel striker, the aluminium incident bar, and the cylindrical specimen. The numerical simulations were conducted using the LS-DYNA commercial software that is an explicit finite element code suitable to analyse dynamic problems with wave propagation involved.

Virtual test specimen in a numerical spallation test

The influence of steel fibre on the tensile strength enhancements and failure pattern was also investigated. Two different fibre ratios were assumed, namely, 0.5 and 2.5 % by volume fraction. SFRC specimens were constructed using straight and round steel fibres that were distributed randomly within the specimen domain. A Matlab code was developed to generate and export the generated fibres into LS-DYNA. Three different striking velocities were applied; they are 4.1, 7.6 and 11.1 m/s.

The results obtained from the numerical simulations are in good agreement with the experimental data in terms of the pull-back velocity of the free end of the specimen and the damage patterns as well the dynamic tensile strength. The effect of steel fibre addition in different ratios can be also seen in the damage process and the failure modes. In conclusion, adding a percentage of steel fibres to the plain concrete or cement-based significantly enhances some of the desired engineering properties.

Report from year book 2018

STAHLFASERVERSTÄRKTER BETON UNTER IMPAKT

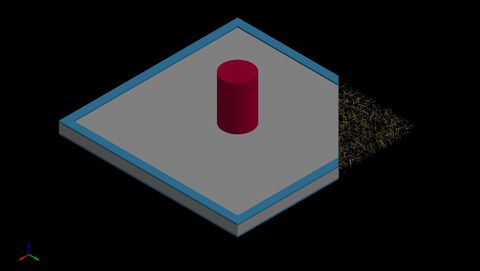

FEM-Modell für Impakt-Tests: Betonplatte mit einer Faserdosierung von 1 % Volumenanteil. Zur Stabilisierung der Probe sind oben und unten Stahlplatten angebracht

The properties of unreinforced concrete and cement-based matrix are well understood. One of the problems of a cement-based matrix is the inherently brittle failure that takes place under impact loading. Steel fibres were applied to enhance the ductility of concrete materials.

Ever since fibre reinforced concrete (FRC) has become a commonly used building material.

It is reported that the addition of steel fibres, typically from 20 to 50 kg/m3 in concrete, can significantly enhance many of the desired engineering properties of hardened concrete such as fracture toughness, flexural strength, resistance to fatigue, high-temperature behaviour as well as splitting. Impact tests are commonly used to investigate the dynamic material properties of the cement-based matrix or plain concrete. In this project, mesoscale numerical models are carried out to investigate the effect of fibre distribution and fibre content on the damage patterns of the concrete structures under various impact loading. The numerical study was conducted using LS-DYNA finite element software. A series of high-velocity impact tests on both, plain and steel fibre reinforced concrete (SFRC) are performed in this study with different fibre dosages and different velocities based on the free-fall formula.

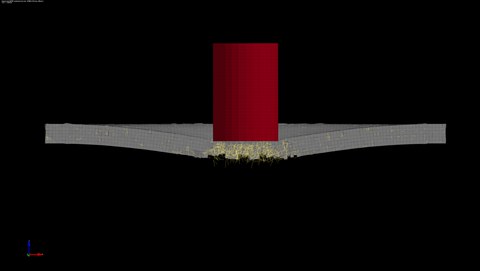

Schadensmuster im numerischen Modell, hier SFRC-Probe mit 3 % Volumenanteil der Faserdosierung und einer Geschwindigkeit von 19,68 m/s

Straight rounded steel fibres of 15 mm length and 1.0 mm diameter are randomly distributed into the concrete matrix using the Matlab programming tool. The steel fibres are modelled with a beam/truss element implemented in LS-DYNA.

The concrete matrix was modelled using eight-noded hexahedron element and the steel fibres were embedded and constrained to move along with these Lagrangian solid elements.

The results obtained from the numerical simulations agree with the experimental data in terms of the residual velocities of the projectile and the damage patterns as well. The effect of steel fibre addition in different percentages can be also seen in the damage process and the failure modes. In conclusion, adding a percentage of steel fibres to the plain concrete or cement-based significantly enhance the properties of this material.