Carbon reinforcement for water impermeable normal concrete

Table of contents

Project data

|

Titel | Title |

Report in the yearbook 2011

Carbon Reinforcement for Water Impermeable Normal Concrete

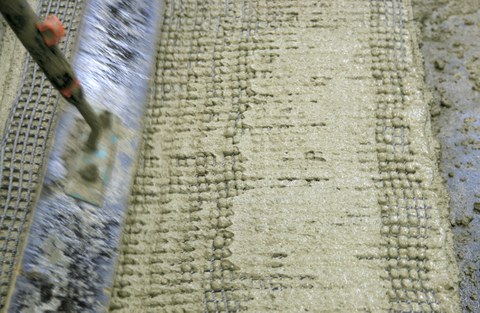

Overlapping joint SGL-GRID 400

This project is an industrial cooperation with the Quinting Zementol GmbH to prove the ability of carbon textiles to design a more water resistant concrete construction. The carbon textile structures are applied as an additional reinforcement in the concrete cover and are therefore located relatively close to the surface. A special manufacturing method of the company made such constructions possible.

The application of carbon reinforcement approximately 5 mm under the concrete surface helps to gain better control of the cracking energy. The carbon fibres absorb a main part of the cracking energy due to the more beneficial static lever arm. The absolute crack width can be reduced radically and therefore the water resistance of such a concrete construction is clearly improved.

To determine the parameters of the carbon textiles, the main testing is done by 4 point bending tests. A special 2D photogrammetry system is used to monitor the cracking itself and the developing of the crack width. Three cameras looking at different parts of the monitoring field make it possible to observe the influence of carbon textiles on crack behaviour and development. The quantity of the crack width is calculated in a second step by means of the taken photos.

With textile structures of approximately 600 g/m ² (SGL GRID 600) it is possible to

limit the crack width under service load from 0.3-0.4 mm to 0.1-0.15 mm. The same can be achieved with a 400 g/m² textile structure (SGL GRID 400) by an additional sanding of the textile.

Along with these laboratory experiments technical installation tests on construction sites and efficiency analyses have been made. It could be shown that the textile can be installed by the special method of the Quinting Zementol GmbH in a firm position. A good bond between concrete matrix and textile could be reached. This demonstrates that textile structures can be put into a normal concrete with a usual aggregate size from

16 to 32 mm and a special fine grained concrete is not necessarily in each application case.

Constructive requirements, such as overlap lengths, can be designed without difficulties. The method is suitable for the use on a construction site and its rough conditions. The chosen carbon textiles are robust enough for this field of application. The project was completed at the end of 2011, a final report is available (in German).

Report in the yearbook 2010

Carbon Reinforcement for Water Impermeable Normal Concrete

Assembling the textile Carbon reinforcement

The project is an industry cooperation promoted by the AiF. The qualification of a additional textile reinforcement layer is examined to get a more or better water impermeable concrete construction. To do this, a carbon textile is put into the 4 to 5 cm strong concrete cover that normally protects the steel reinforcement. This is an additional reinforcement layer in the concrete cover that will be laying very close to the surface. It can be assumed that this reinforcement, close to the surface, will take a lot of the cracking energy, not only due to bending. So the crack wide will be reduced significantly and it will help to get a more water impermeable concrete.

It is another effect that the so done more compact concrete material in the concrete cover will probably allow to reduce the thickness of this concrete cover by getting the same protection effect to the steel reinforcement.

Processing

The procedure of installation is nearly the same as working with normal concrete with maximal aggregate 32 to 64 mm. The textile carbon reinforcement is put onto the surface and worked in 5 to 7 mm. There is no special matrix to get an optimal interaction between the filament of the carbon reinforcement and the concrete matrix, like used in TRC.

The working in of the textile reinforcement is done by a special procedure of the company, Quinting Zementol GmbH. A light modified normal concrete is used, but this modification is done at the building side. Currently the qualification and performance of the construction is tested by 4 point bend tests. A special 2D photogrammetry system was developed to monitor the cracking process.

Results

The textile carbon reinforcement can be installed in the required depth in laboratory and at field work. In the 4 point bend test a positive influence of the textile reinforcement is clearly shown. Installation tests on a building site also have been done successfully.