Tests on noise barrier elements

| Titel | Title Experimentelle Untersuchungen zur Tragfähigkeit und Ermüdungsfestigkeit von Lärmschutzwandelementen | Experimental investigations on the load bearing capacity and fatigue resistance of noise barrier elements Auftraggeber | Client EUDUR-Bau GmbH & Co. KG, Herzebrock-Clarholz Zeitraum | Period Seit | since 03/2021 Leiter | Project manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Team | Team Dennis Birkner, M.Sc., Dipl.-Ing. Clara Schramm, Dr.-Ing. Torsten Hampel, Dipl.-Ing. (FH) Sabine Wellner, Tino Jänke, Heiko Wachtel, Bernd Wehner Projektpartner | Project partner Ingenieurbüro Prof. Dr.-Ing. Robert Hertle, Gräfelfing |

Report 2022

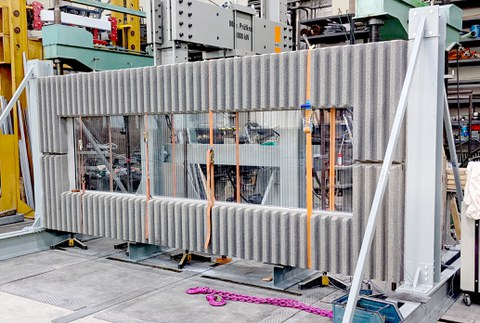

Noise barrier element in the test setup

As part of the application to the German Federal Railway Authority (EBA) for approval of noise barrier elements with transparent enclosures on high-speed railroad lines, the Institute of Concrete Structures of Technische Universität Dresden was commissioned by the company EUDUR-Bau GmbH & Co. KG. to carry out the necessary experimental investigations as a basis for the evaluation of the wall elements.

The significant loads on such noise protection wall elements result from the compression-suction effect of the train traffic. The associated dynamic factor increases disproportionately with increasing train speeds so that, in combination with very high numbers of load cycles, this results in fatigue loads that must be considered. The analytical verifications of fatigue for reinforced concrete components are generally to be carried out in accordance with DIN Technical Report 102. However, in the present case this is not possible for all required verifications. Therefore, a test program was coordinated in advance with the engineering office of Prof. Dr.-Ing. Robert Hertle in order to provide verification of the suitability of the EUDUR wall elements for the intended use.

Tests on full wall elements were carried out in the Otto Mohr Laboratory as part of the test program. These included a static test up to bending failure, natural frequency tests in the undamaged and in the cracked state, and a fatigue test in which a wall element was subjected to the decisive compression-suction load from train traffic for five million load cycles. In order to apply the required forces as evenly as possible to the wall elements, appropriate load distribution structures were designed. For the static test, the construction consisted of hinged connected steel profiles and, for the fatigue test, of an aluminum structure that surrounded the wall element for the application of the alternating load on both sides.

Together with accompanying small component tests and analytical and numerical verifications, the systematic evaluation of the tests carried out provide the basis for the technical approval of the wall element.