RUBENS: Rapid and Unique Business Transformation by Extended Sensing for Next Generation Process Sites

Project Information

|

Project Manager: |

|

|

Staff: |

|

| Project duration: |

09/2022 - 07/2026 |

| Type of financing: |

Industrial Project |

| Funding agencies: |

LANXESS Deutschland GmbH, |

| Project partners: |

LANXESS Deutschland GmbH |

Project description

As a result of volatile markets, increasing demands on energy efficiency and changing customer needs, operators of chemical plants have the responsibility and pressure to continuously optimize existing processes. However, the limited information provided by existing EI&C instruments in brownfield plants is usually insufficient to derive measures and concepts for optimization purposes.

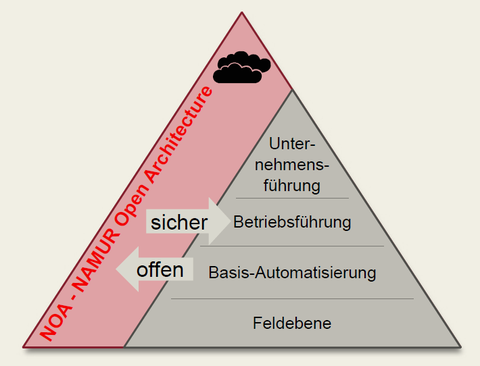

Shematic depiction of NOA

The use of new communication technologies such as APL (Advanced Physical Layer) with suitable interfaces is a promising remediation which provides a significantly higher amount of process data quickly and securely. For this reason, the first focus of the project is to examine how process data can be provided flexibly via the help of APL-devices and the second channel of the NAMUR Open Architecture (NOA) for monitoring and optimization purposes.

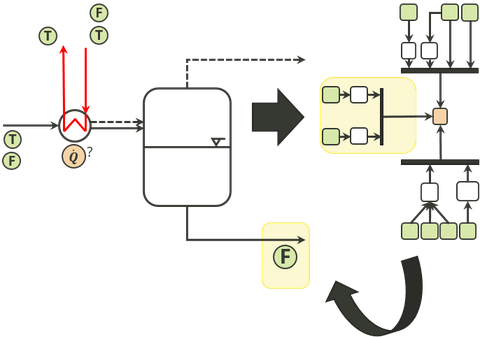

Shematic depiction of optimizing a soft sensor by adding new EI&C equipmentframework

Secondly, the project aims to investigate how model-based methods for online optimization (e.g. soft sensors) can be improved using data streams from the second channel and by introducing new EI&C technology. A main objective is to systematically derive valuable data streams from simulation and information models. Realization of required information streams can be achieved efficiently by using e.g. APL and NOA.

Throughout this project, methods and results are tested and validated in a large-scale chemical plant. APL-capable actuators and sensors as well as process nodes that combine control and measurement capability in a single instrument are deployed.

© TUD

© TUD

Research Assistant

NameMr M.Sc. Lukas Furtner

Hybrid Modeling, Simulation & Opimization Group

Send encrypted email via the SecureMail portal (for TUD external users only).

Process Systems Engineering Group

Process Systems Engineering Group

Visiting address:

Merkelbau Helmholtzstraße 14

01069 Dresden

Visiting address:

Barkhausen-Bau, BAR/E30 Helmholtzstr. 18

01069 Dresden