TP C3-V2.5A-I-b: Simulation des Verbundes zwischen Carbonstrukturen und Beton

Inhaltsverzeichnis

Projektdaten

|

Titel | Title |

Bericht aus dem Jahrbuch 2020

ENTWICKLUNG NEUER CARBONSTÄBE

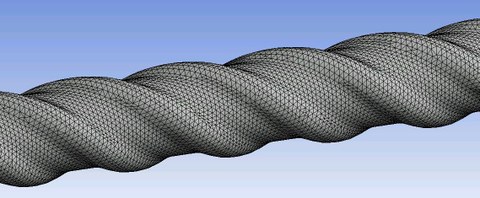

FE-Modell des helixförmigen Carbonstabs

Neben den textilen Gelegen aus Carbon haben sich auch nichtmetallische Stäbe mit hohen Tragfähigkeitspotentialen als mögliche Bewehrungsalterantive zu den herkömmlichen Stahlstäben hervorgetan. Wie bei den Carbongelegen können die Materialeigenschaften zwischen den verschiedenen Carbonstäben sehr stark schwanken, bedingt durch unterschiedliche Herstellverfahren, Tränkungen oder Geometrien. Besonders bei den möglichen Oberflächenausbildungen, beispielsweise nachträglich aufgebrachte oder eingefräste Profilierungen, variieren die Stäbe deutlich stärker als dies bei den verschiedenen Gelegen der Fall ist. Diese Maßnahmen dienen dazu, den Verbund zwischen dem Carbonstab und der Betonmatrix zu verbessern und damit die Tragfähigkeit der Bewehrung im Bauteil zu steigern. Zu beachten bei der Entwicklung einer solchen verbundverbessernden Maßnahme ist das bei Carbonwerkstoffen vorliegende anisotrope Materialverhalten. Zusätzlich, zu den aus dem Stahlbetonbau bekannten Verbundversagensarten, kann es auch zu einem Abscheren der Carbonprofilierung kommen, welches überwiegend durch die Scherfestigkeit der Tränkung gesteuert wird. Sehr gute Verbundergebnisse wurden mit nachträglich in den Stab eingefrästen Rippen erzielt, die aber ökologisch und ökonomisch durch „verlorenes“ Material nicht zielführend sind.

Aus diesem Grund wurde vom Intitut für Leichtbau u nd Kunstofftechnik der TU Dresden ein Verfahren entwickelt, bei dem pultrudierte Stäbe mit einer Thermoplastmatrix nachträglich durch eine eigens entwickelte Düse gezogen werden, um eine helixförmige Oberflächenprofilierung in den Stab einzuprägen. Der Vorteil bei diesem Verfahren besteht darin, dass die Garne dabei nicht beschädigt werden und außerdem keine geometrische Trennung der Profilierung von dem Stabkern besteht, wodurch ein hoher Ausnutzungsgrad des verwendeten Materials zustande kommen soll.

Da es bei ersten Verbundversuchen mit diesem Stab zu einem Ausdrehen aus dem Betonkörper kam, soll im nächsten Schritt seitens des Instituts für Massivbau eine numerische Untersuchung durchgeführt werden, um feststellen zu können, ob sich durch eine erhöhte Rauigkeit der Oberfläche oder geometrische Anpassungen eine Optimierung des Verbunds erzielen lässt. Variiert werden dabei u. a. die Rippenneigung oder auch die Rippenabmessungen.

Als Endprodukt soll ein Stab vorliegen, der durch verschiedene in diesem Projekt definierte Optimierungen ein gutes Verbundverhalten aufweist und durch dessen Herstellung kein Materialverlust entsteht.

Bericht aus dem Jahrbuch 2019

VERBUNDSIMULATION VON CARBONSTÄBEN

Verschiedene Geometrien von Carbonstäben

Carbonbewehrte Bauteile können extrem tragfähig sein. Die Forschung beschäftigt sich bisher größtenteils mit den textilen Carbongelegen, aber auch Carbonstäbe zeichnen sich durch ihre hohe Festigkeit in Längsrichtung aus. Die im Gegensatz zu Stahlstäben erhöhte Querdruckempfindlichkeit bringt jedoch auch einige Herausforderungen mit sich, insbesondere im Hinblick auf die Wahl geeigneter Verankerungen und Oberflächenprofilierungen.

Zur Etablierung von Carbonstäben ist im Bauwesen eine gezielte Ausnutzung ihres hohen Tragfähigkeitspotentials erforderlich, weshalb die bereits erarbeiteten grundlegenden Bewehrungsstabstrukturen weiterentwickelt und u. A. durch neue innovative Oberflächenstrukturierungen ergänzt werden.

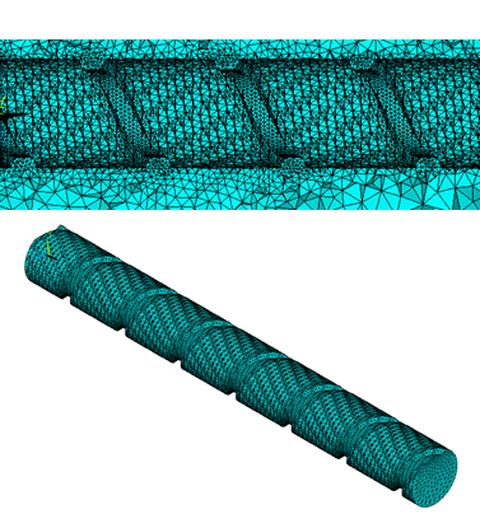

Dreidimensionale Modellierung eines Auszugversuchs und eines Carbonstabs

Im Vorhaben C3-V2.5A ist die Aufgabe des Instituts für Massivbau die numerische Simulation des komplexen Verbundverhaltens zwischen Carbonstäben und Beton. Hierbei steht insbesondere die konstruktive Gestaltung der Carbonstäbe für einen ausreichenden Form- bzw. Kraftschluss zur Sicherstellung der Verbundwirkung unabhängig vom Tränkungsmaterial im Mittelpunkt des Projektes. Dazu wurden ein von den Projektpartnern verwendeter Carbonstab ausgemessen und als 3D-Modell in ein Finite-Element-Programm eingearbeitet sowie eine zweidimensionale Vereinfachung des Versuchs erstellt, die deutlich weniger Rechenleistung benötigt. Anhand experimenteller Versuche der Projektpartner sollen die verschieden detaillierten FEM-Modelle kalibriert und validiert werden, sodass die Versuche nachgebildet werden können. Anschließend erfolgt eine ausführliche numerische Parametervariation, um weiterführende Erkenntnisse über das Verbundverhalten der gerippten Carbonstäbe mit dem umgebenden Beton und möglichen Versagensmechanismen zu erlangen. Darauf aufbauend kann das Verbundverhalten von Carbonstäben analog zum Stahlbetonbau klassifiziert werden.

Aus den Erkenntnissen dieser numerischen Simulationen soll es schlussendlich möglich sein, eine weitestgehend effiziente Oberflächenprofilierung der Carbonstäbe zu ermitteln, die eine großserienfähige Produktion und den wirtschaftlichen Einsatz ermöglichen.